Magnetron driving power supply

A technology for driving power supply and magnetron, which is applied in the direction of improving the efficiency of home appliances, microwave heating, sustainable buildings, etc. Small size, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

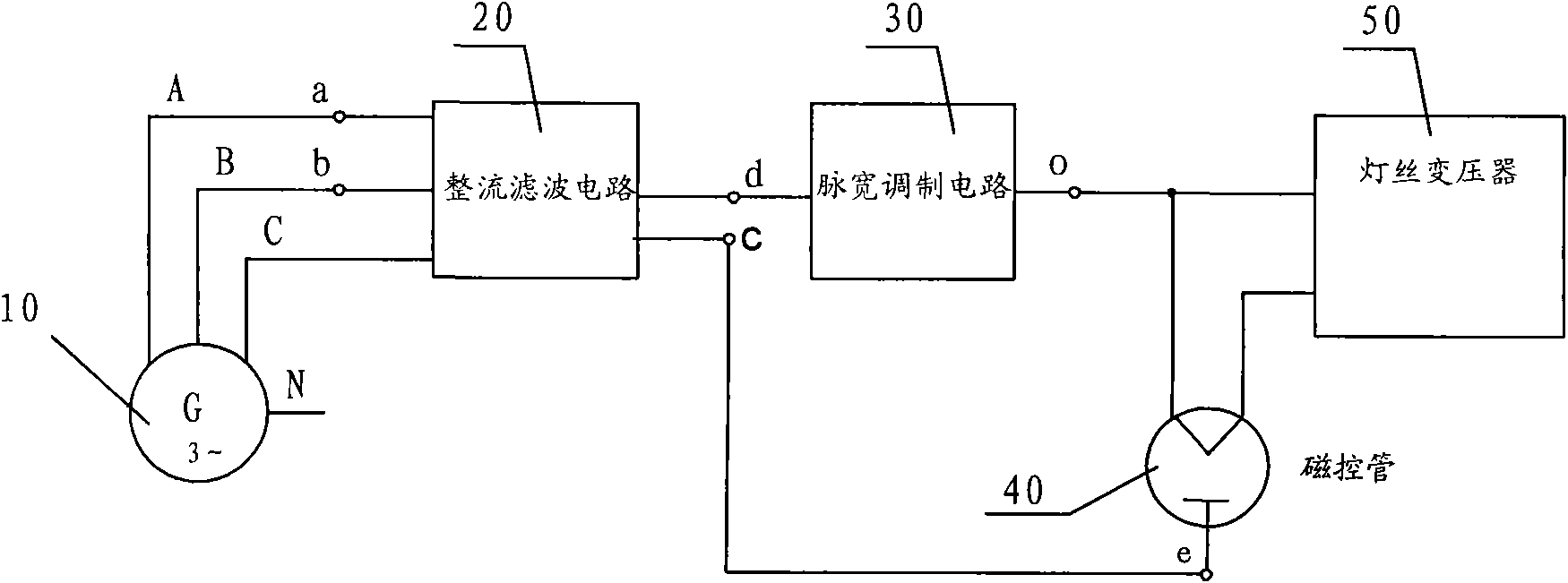

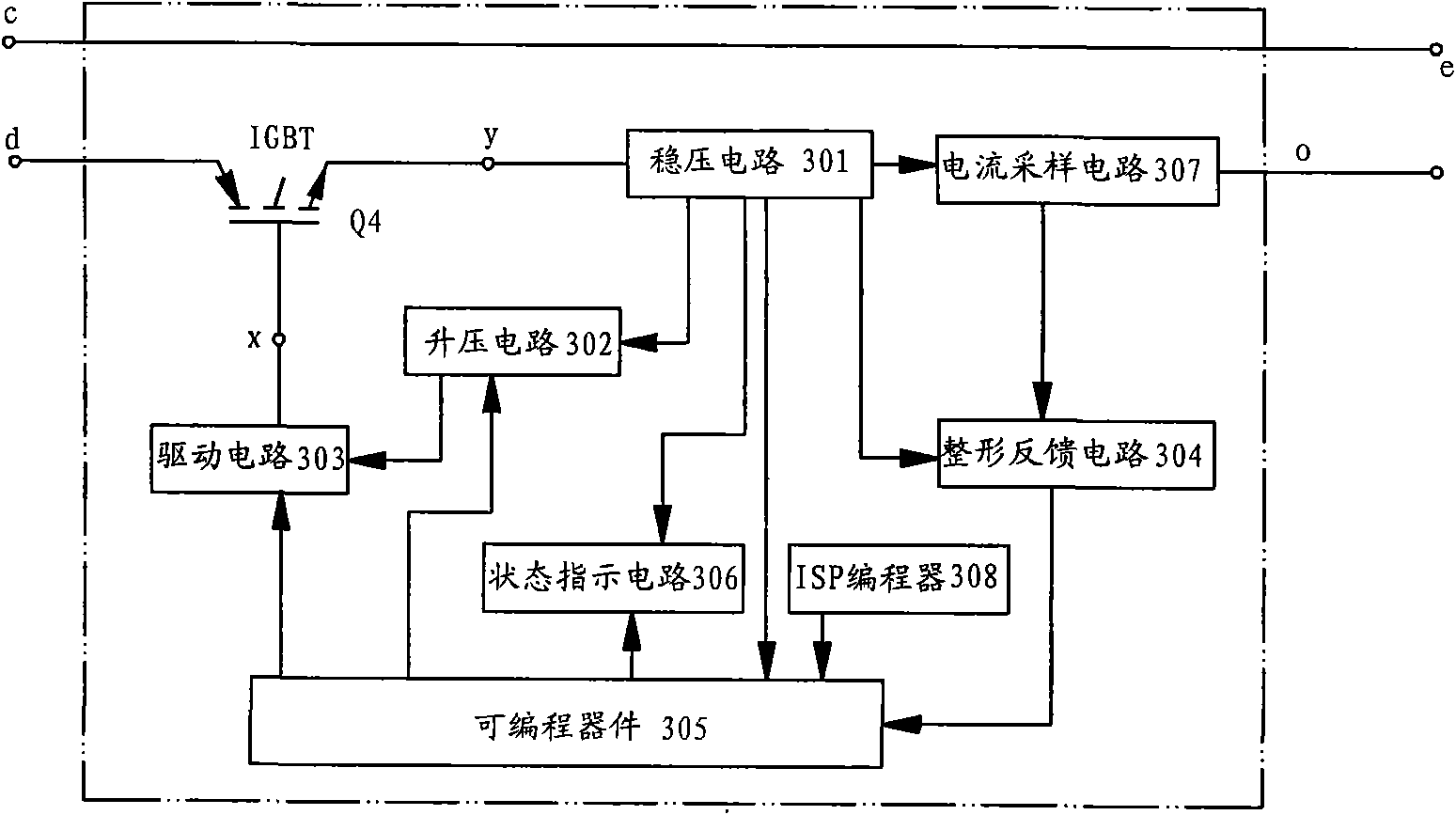

[0024] see Figure 1-Figure 7 , the magnetron drive power supply includes a high-voltage three-phase generator set 10, a rectifier filter circuit 20, a pulse width modulation circuit 30, and more than one magnetron 40, a filament transformer 50, and the high-voltage power generated by the high-voltage three-phase generator set 10. After being rectified and filtered by the filter circuit 20, it is input to the pulse width modulation circuit 30. After the output of the pulse width modulation circuit, it is respectively input to the magnetron 40 and the filament transformer 50. After the filament transformer is transformed, it is input to the magnetron. The final output current is a pulse current with a fixed cycle and a variable duty cycle.

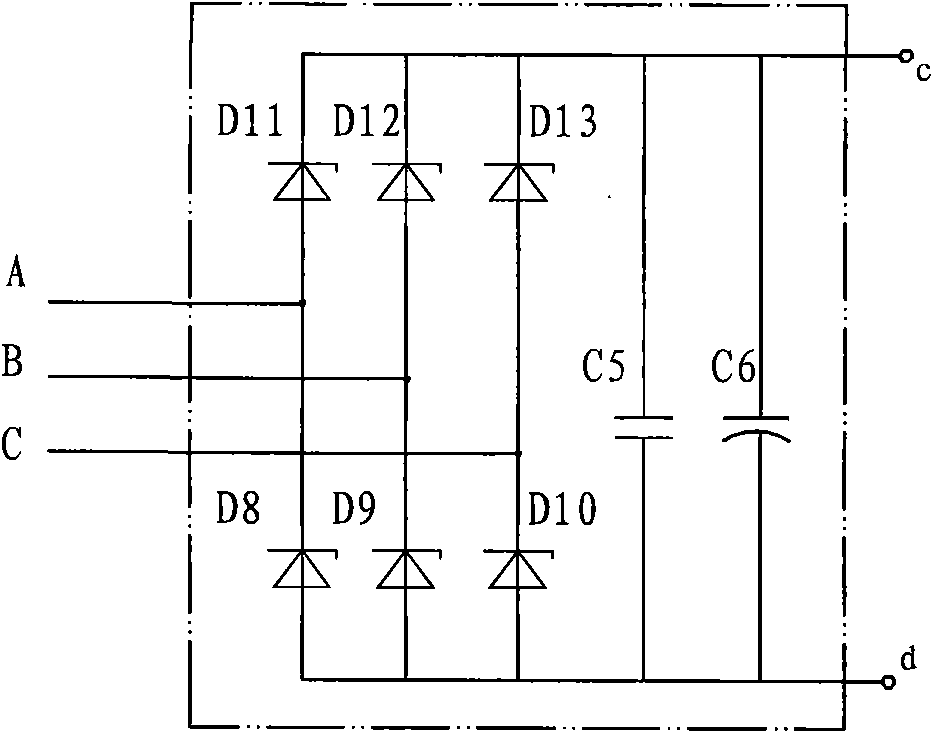

[0025] The rectification filter circuit 20 includes diode D8, diode D9, diode D10, diode D11, diode D12, diode D13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com