Method for preparing walnut oil and formulated product taking walnut oil as stroma

A technology of walnut oil and walnut kernels, which is applied in the field of formula products, can solve the problems of waste of resources, easy wear and tear of press machines, and dark oil color, etc., and achieve the effect of increasing pressing hardness, increasing oil yield, and preventing oil color from being too dark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

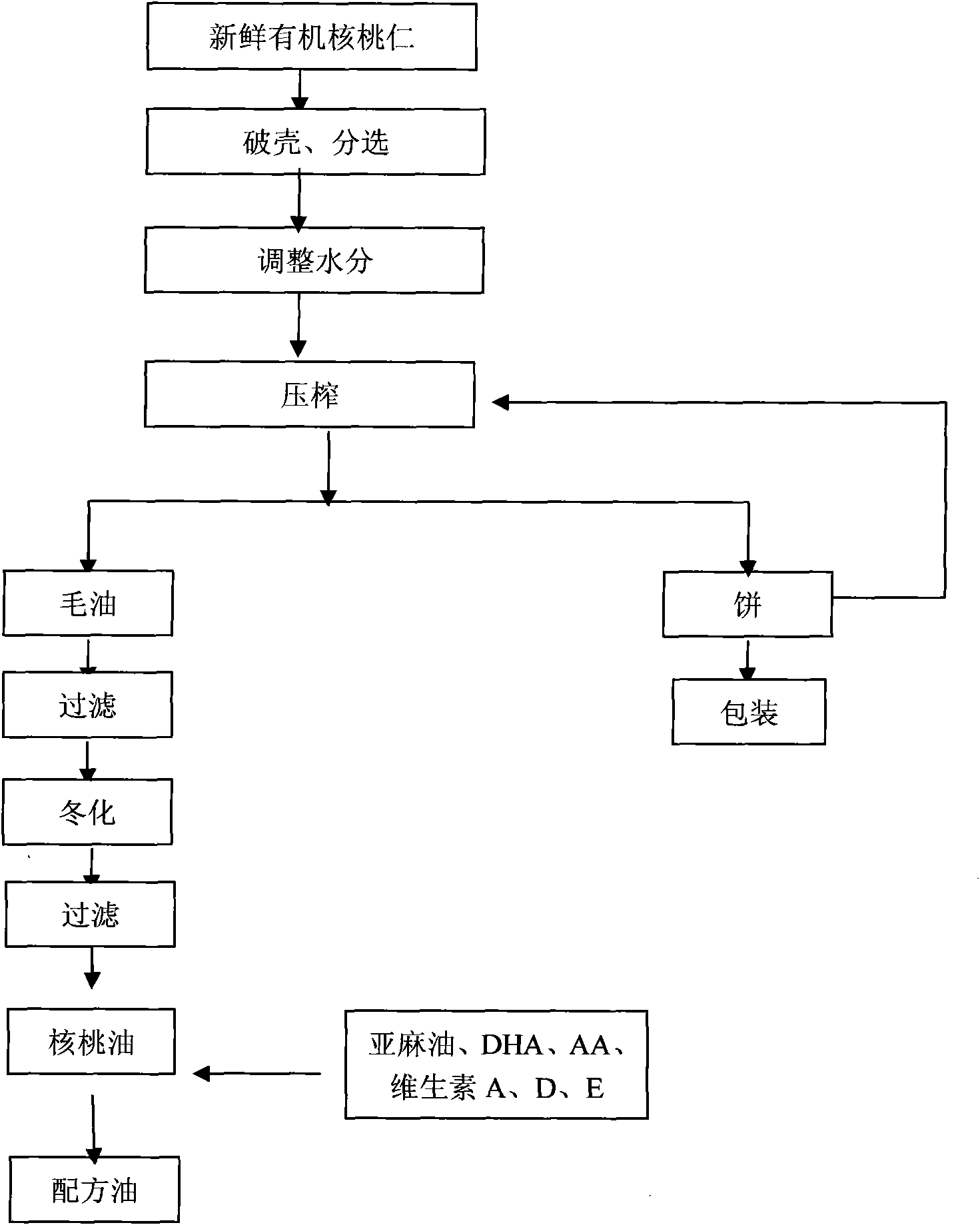

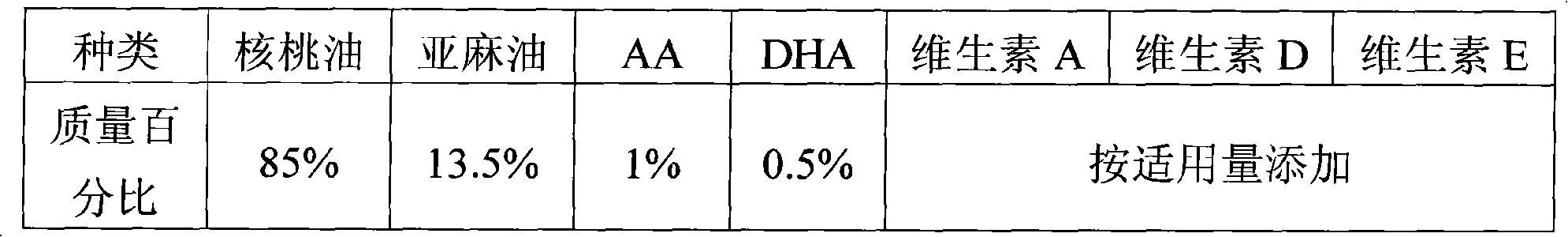

Method used

Image

Examples

Embodiment 1

[0033] 1. Select high-quality and qualified walnuts, and remove moldy and deteriorated walnuts. Broken the shell manually, separated the shell and kernel;

[0034] 2. Evenly sprinkle purified water into the walnut kernels, and adjust the water content to 8%;

[0035] 3. Turn on the heating system of the pressing machine, adjust the adjusting screw of the pressing machine, and slowly adjust the thickness of the cake to 3-4mm; the pressing temperature is controlled at 120°C;

[0036] 4. Mix the molded cake and walnut kernels evenly at a ratio of 1:3, adjust the water content to 8%, and squeeze. Pack the biscuit mixture after being squeezed 3 times by machine;

[0037] 5. The crude oil is added with a filter aid accounting for 1% of the total oil weight, stirred to disperse evenly in the crude oil, pumped into the plate and frame filter, and circulated and filtered until clarified, with a filtration pressure of 0.3Mpa;

[0038] 6. Cool the oil to about 0°C, keep it warm for 15...

Embodiment 2

[0047] 1. Select high-quality and qualified walnuts, and remove moldy and deteriorated walnuts. Broken the shell manually, separated the shell and kernel;

[0048] 2. Sprinkle pure water evenly in the walnut kernels, and adjust the water content to 15%;

[0049] 3. Turn on the heating system of the pressing machine, adjust the adjusting screw of the pressing machine, and slowly adjust the thickness of the cake to 4-5mm; the pressing temperature is controlled at 140°C;

[0050] 4. Mix the molded cake and walnut kernels at a ratio of 1:5, adjust the water content to 15%, and press. Pack the biscuit mixture after being squeezed 3 times by machine;

[0051] 5. Add filter aids accounting for 1.5% of the total oil weight to the crude oil, stir to disperse evenly in the crude oil, pump it into the plate-and-frame filter, and carry out circulating filtration until clarification, with a filtration pressure of 0.3Mpa;

[0052] 6. Cool the oil to about 0°C, keep it warm for 30 hours, ...

Embodiment 3

[0055] 1. Select high-quality and qualified walnuts, and remove moldy and deteriorated walnuts. Broken the shell manually, separated the shell and kernel;

[0056] 2. Sprinkle pure water evenly in the walnut kernels, and adjust the water content to 5%;

[0057] 3. Turn on the heating system of the pressing machine, adjust the adjusting screw of the pressing machine, and slowly adjust the thickness of the cake to 1-3mm; the pressing temperature is controlled at 160°C;

[0058] 4. Mix the molded cake and walnut kernels at a ratio of 1:0.5 evenly, adjust the water content to 5%, and press. Pack the biscuit mixture after being squeezed 3 times by machine;

[0059]5. Add filter aids accounting for 1.4% of the total oil weight to the crude oil, stir to disperse evenly in the crude oil, pump it into the plate-and-frame filter, and carry out circulating filtration until clarification, with a filtration pressure of 0.3Mpa;

[0060] 6. Cool the oil to about 0°C, keep it warm for 5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com