Wavelike finned type cold accumulation heat exchanger

A heat exchanger and wave-shaped technology, applied in the field of heat exchangers, can solve problems such as structure and size that cannot meet technical requirements, and achieve the effects of improving heat exchange effect, uniform heat transfer, and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

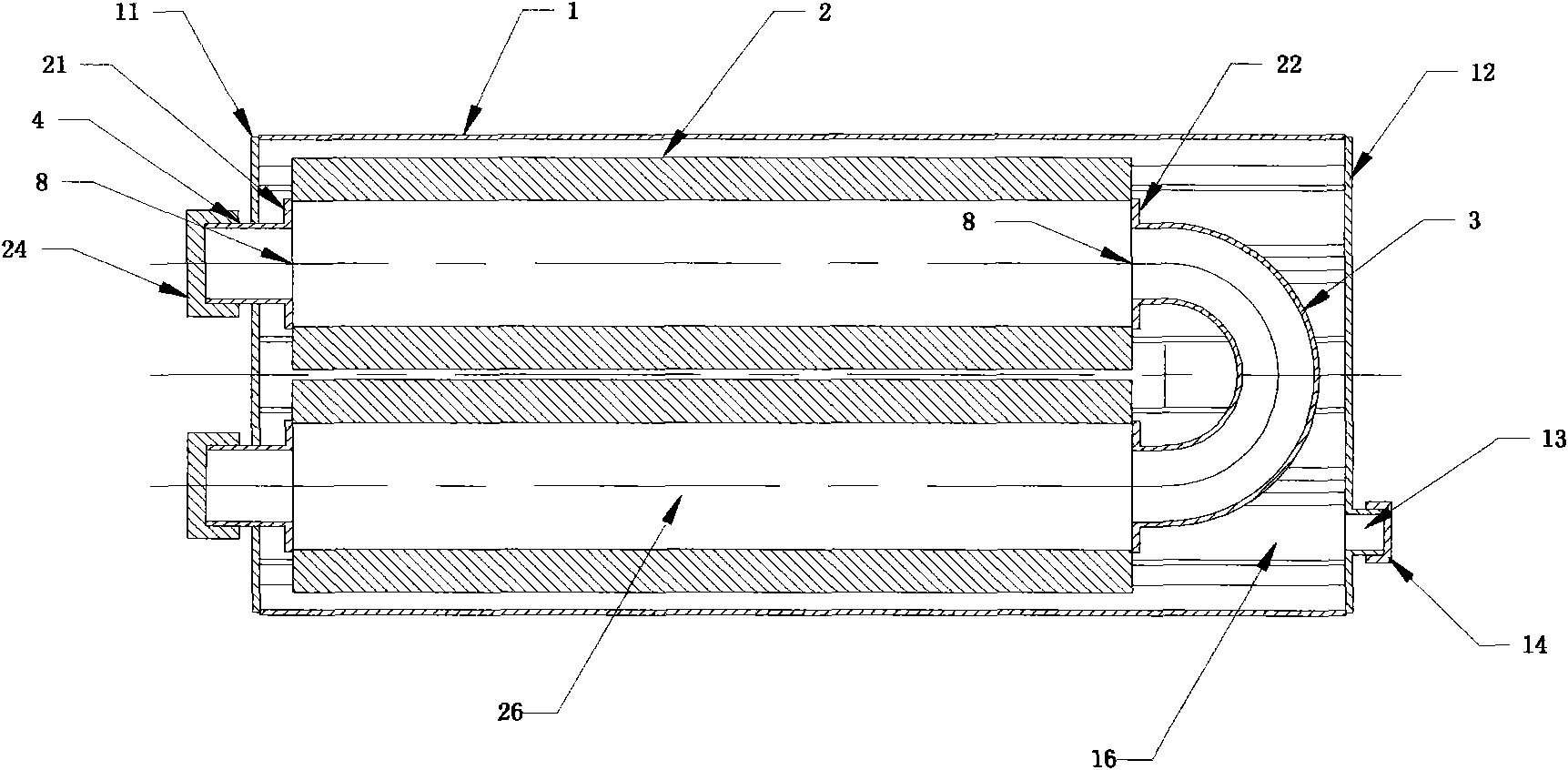

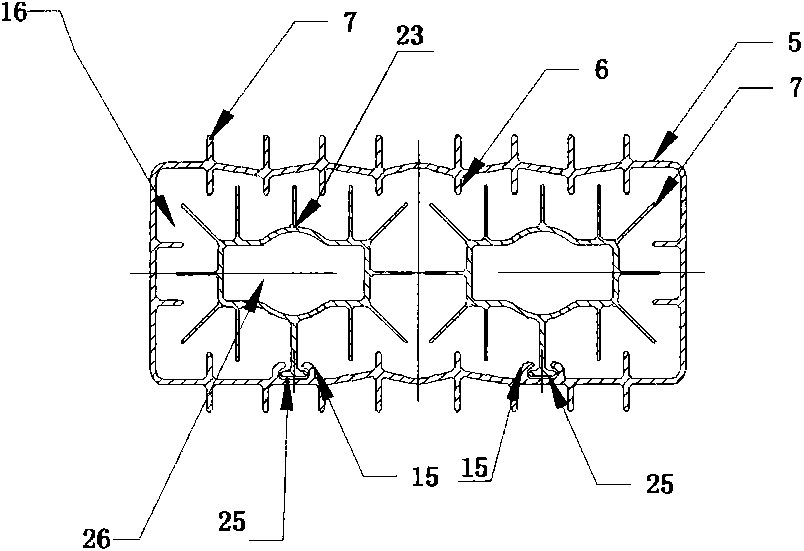

[0021] Such as figure 1 , 2 As shown, the present invention discloses a heat exchanger, wherein figure 2 for figure 1 The A-A cross-sectional view includes an outer pipe 1, an inner pipe 2, an elbow 3, and a joint 4. Wherein the front end of the outer tube 1 is welded with an outer tube front seal 11, the rear end is welded with an outer tube rear seal 12, the rear seal 12 of the outer tube is provided with a perfusion hole 13, and the perfusion hole 13 is provided with a rear cover 14. The inner tube 2 is located side by side in the inner cavity of the outer tube 1. The inner tube 2 has an inner tube front sealing piece 21 welded on the front end surface, and an inner tube rear sealing piece 22 welded on the rear end surface. There are two inner tubes 2, which can also be There are three or four and more than all can, the openings at both ends of the elbow 3 are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com