TPE material magnetic gasket for refrigerator and freezer and manufacture method thereof

A manufacturing method and refrigerator technology are applied in the field of thermoplastic elastomer and TPE material magnetic door seals, which can solve the problems of shortened service life, poor sealing, low mechanical strength, etc. The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

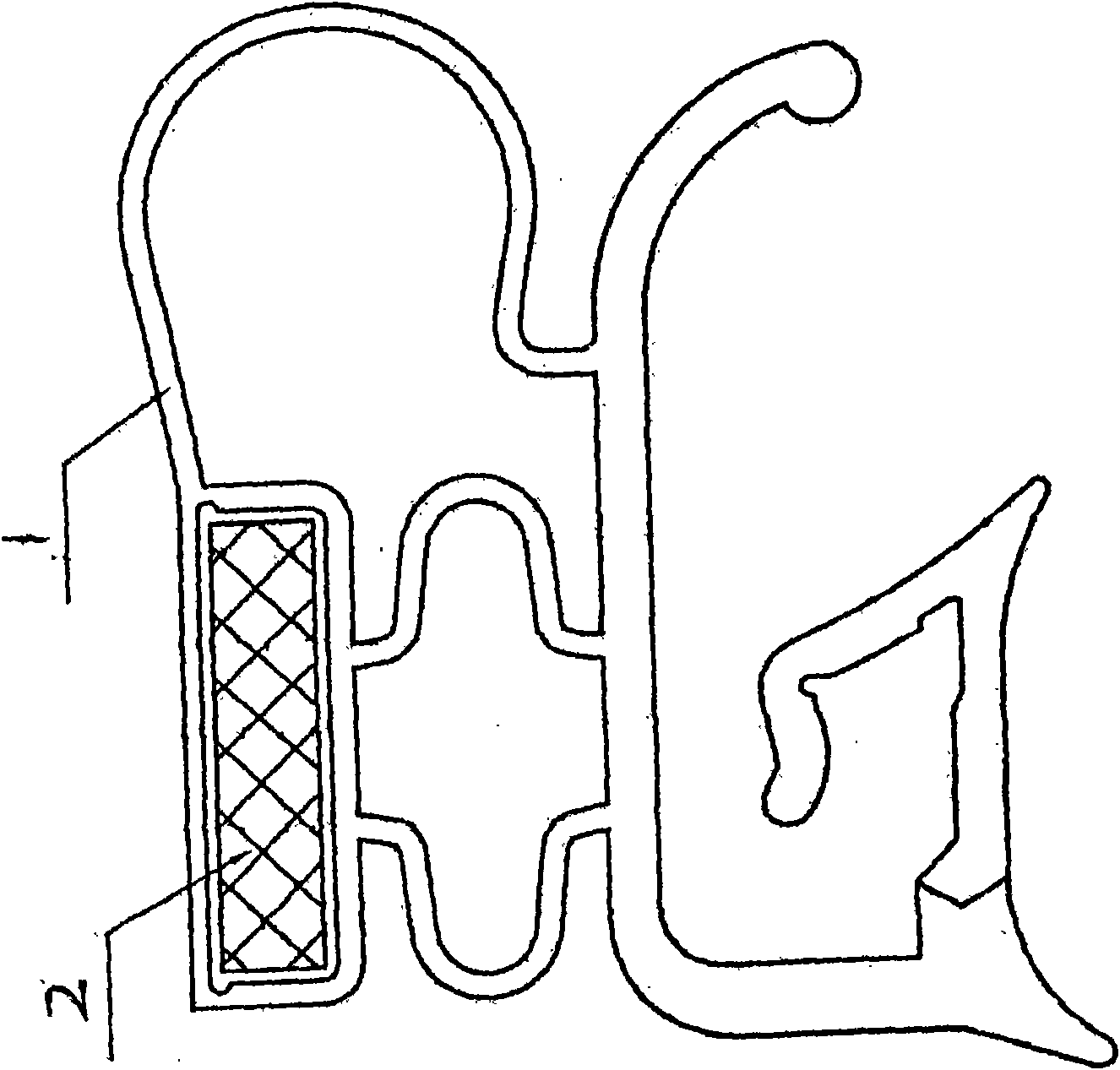

[0033] like figure 1 Shown is a magnetic door seal made of TPE material for refrigerators and freezers. The material of the magnetic door seal made of TPE is a thermoplastic elastomer blended with SEBS / PP, and its structure includes a TPE elastomer door seal rubber sleeve 1. The TPE elastomer door seal rubber sleeve 1 is pierced with a magnetic strip 2, and the TPE elastomer door seal rubber sleeve 1 is mainly composed of the following raw materials by weight:

[0034] SEBS 40-45 copies;

[0035] PP 15-18 parts;

[0036] PE 3-5 copies;

[0037] 25-30 parts of white oil;

[0038] 5-8 parts of CaCO3;

[0039] Lubricant 1.3-1.5 parts;

[0040] Antioxidant 0.2-0.8 parts;

[0041] Appropriate amount of pigment.

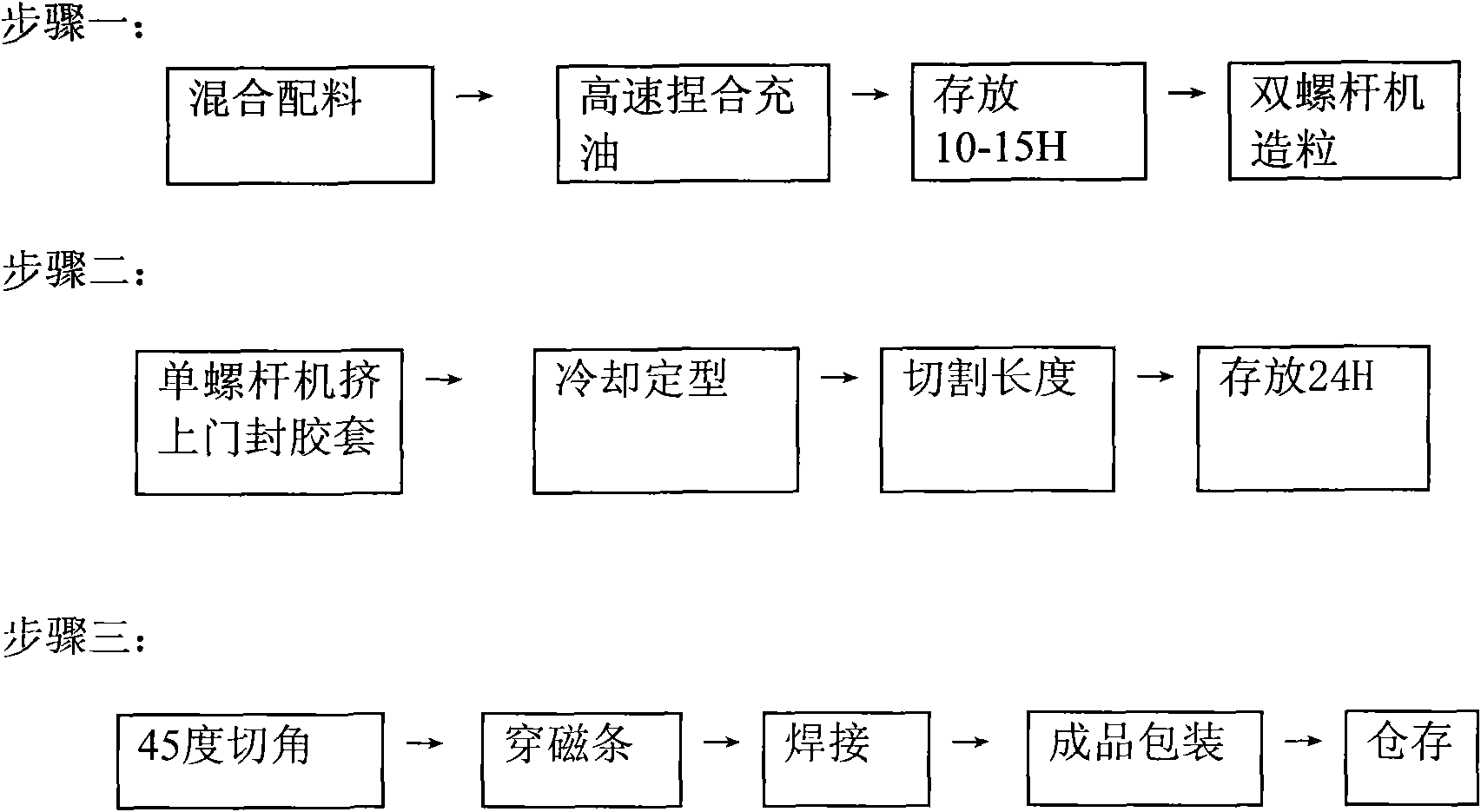

[0042] like figure 2 As shown, a method for preparing the above-mentioned magnetic door seals made of TPE material for refrigerators and freezers comprises the following steps:

[0043] Step 1: After mixing the raw materials of the above-mentioned TPE elastomer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com