Preparation method for fabry-perot sensor based on corroded high doping optical fiber

A manufacturing method and high-doping technology, applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of poor mechanical strength, small fiber diameter, and difficult welding of Philips sensors, and achieve low cost, reduce corrosion, and reduce corrosion. The effect of reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

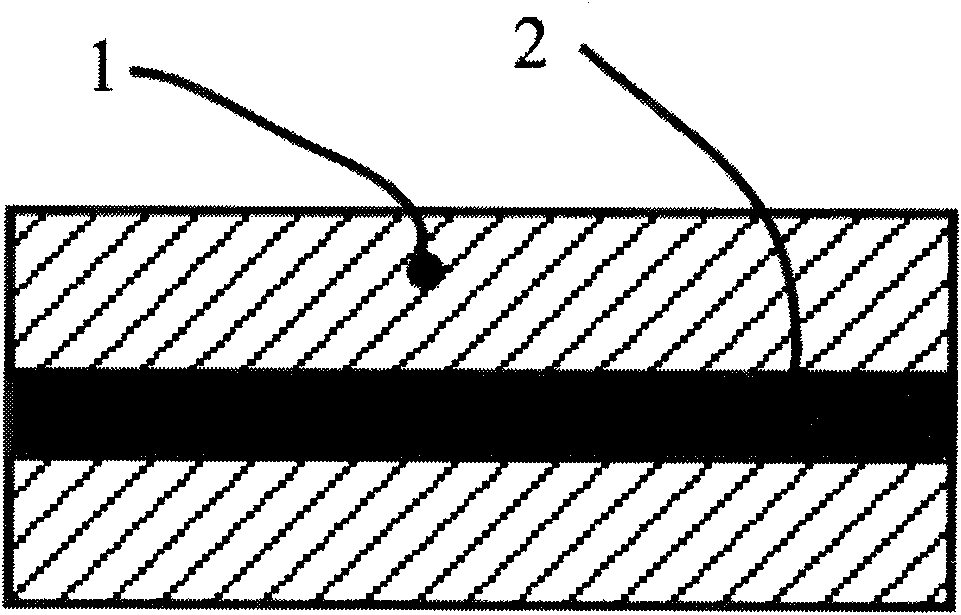

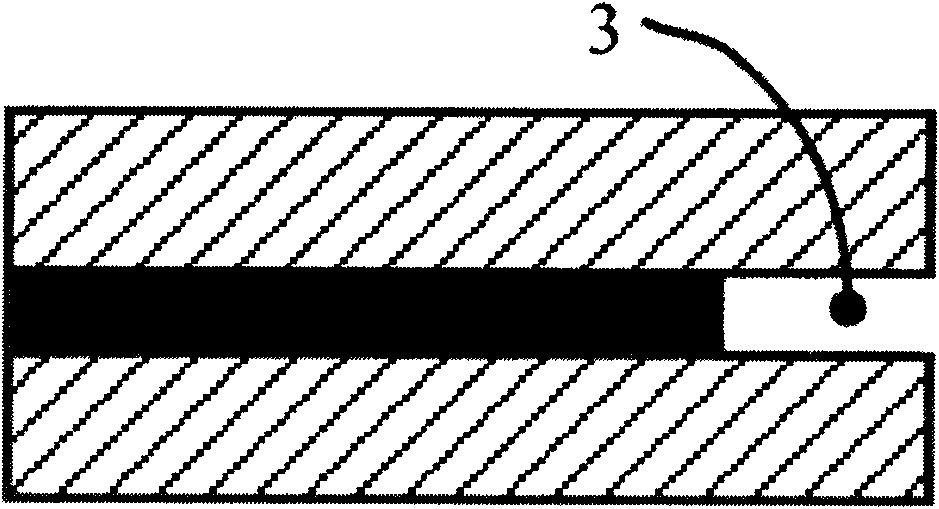

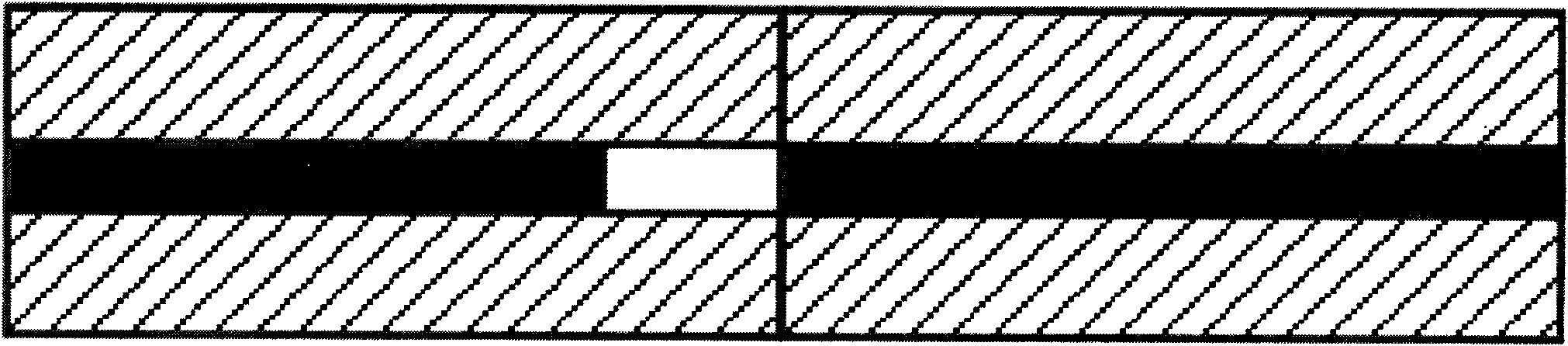

[0023] The schematic diagram of the manufacturing method of fiber Fabry Perot sensor based on corrosion of highly doped fiber is as follows Figure 1 ~ Figure 3 Shown. First, a 40% mass ratio of hydrofluoric acid solution and a 35% mass ratio of hydrochloric acid solution were made into an etching solution with a total volume of 60 mL at a volume ratio of 3:1. The highly doped fiber uses the erbium-doped single-mode fiber of Nufern, the model is EDFC-980-HP. Cut the end face of the erbium-doped fiber flat, such as figure 1 As shown above, put the corrosive liquid into the corrosive processing. After 25 minutes, take out the corroded erbium-doped fiber and soak it in deionized water for about 20 minutes to wash away the remaining corrosive liquid, and then place it in a dust-free environment to dry or blow it dry with a hair dryer for later use. The core part of the fiber end face will be corroded into a micro-hole, and the three-dimensional profile of the actually corroded fiber e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com