TFT-LCD array substrate structure and manufacturing method thereof

An array substrate structure and thin-film transistor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of low jump voltage, small storage capacitance, and affecting the display quality of thin-film transistor liquid crystal displays, etc., to achieve Reduced jump voltage, increased storage capacitance, and improved display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

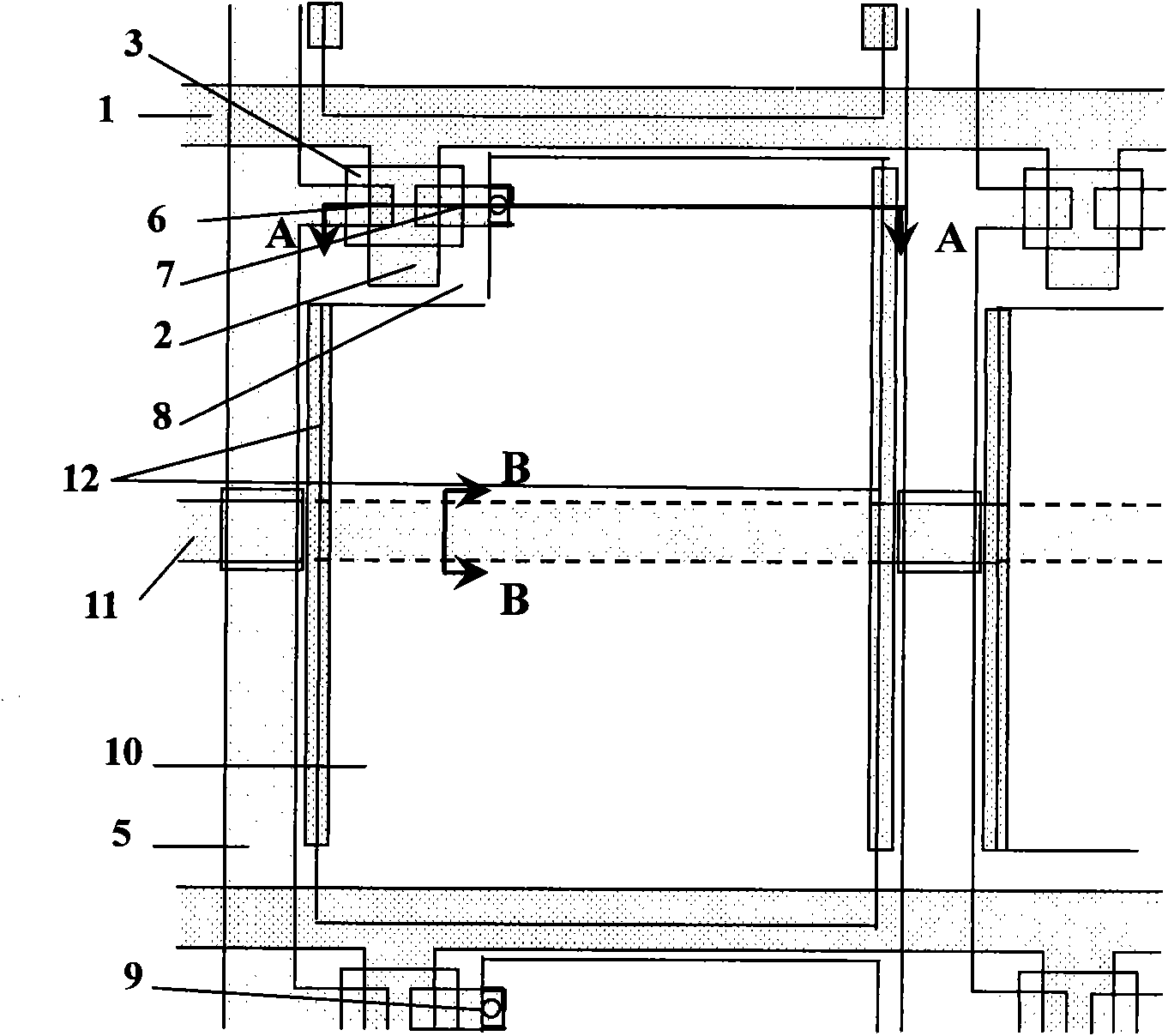

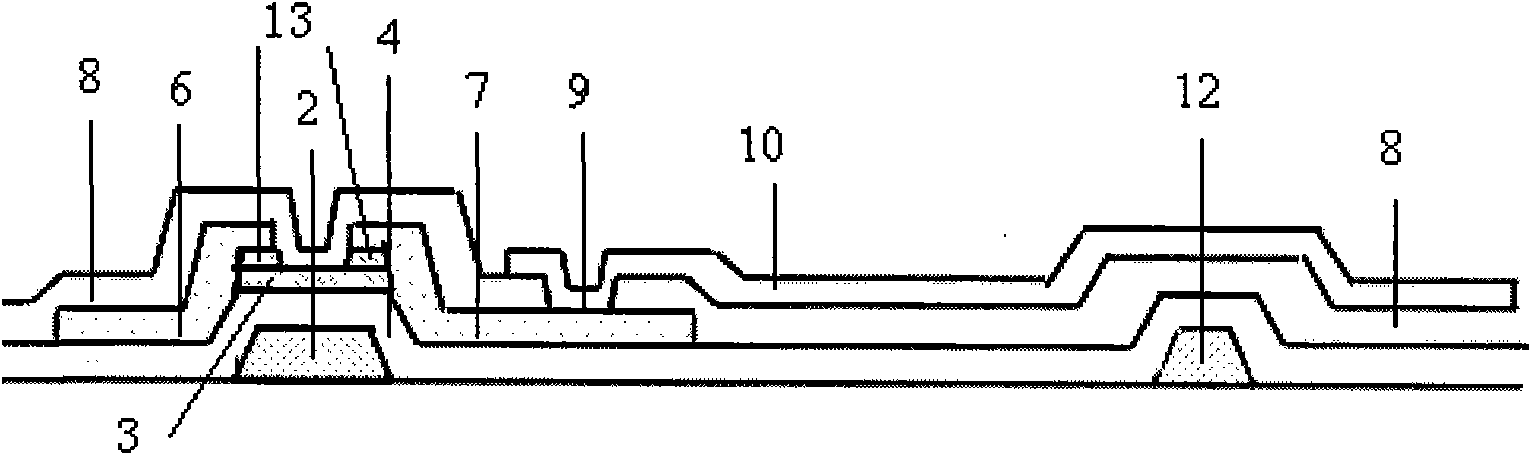

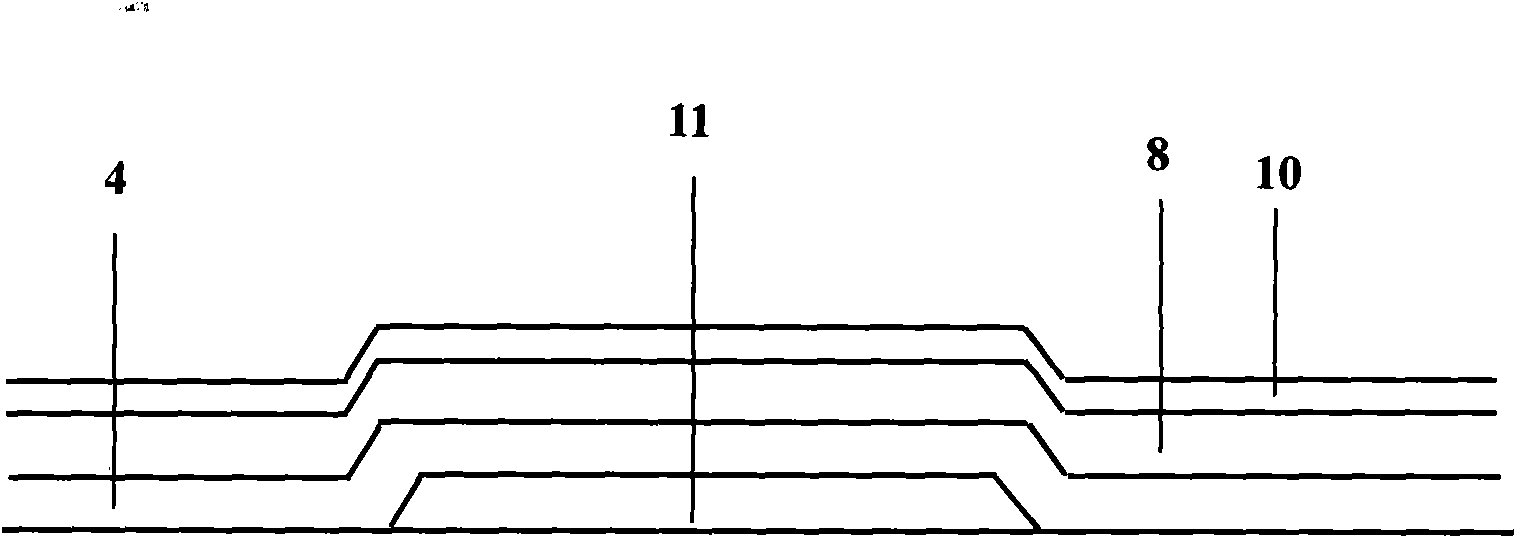

[0042] In order to solve the problem of poor display quality of liquid crystal display panels in the prior art, the present invention provides a thin film transistor liquid crystal display array substrate structure. Such as image 3 , Figure 3a As shown, the array substrate structure includes: gate scanning lines 1 and data scanning lines 5 formed on the substrate, and pixel electrodes 10 are formed in pixel regions defined by adjacent gate scanning lines 1 and data scanning lines 5, And form a thin film transistor at the intersection; the composition structure of the thin film transistor is as follows from bottom to top: gate electrode 2, gate insulating layer 4, transparent conductive layer (not marked in the figure), source electrode 6 and drain electrode 7, Ohmic contact layer 13 , semiconductor layer 3 , passivation layer 8 . The structure of the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com