Method of honeycomb molding pretreatment for burning and system for honeycomb molding pretreatment for burning

A molded body and pretreatment technology, which is applied to ceramic molding machines, furnace types, and drying solid materials, etc., can solve problems such as slowing down the heating rate, damage, and large environmental loads, and achieves suppression of deformation, suppression of deformation, and short drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

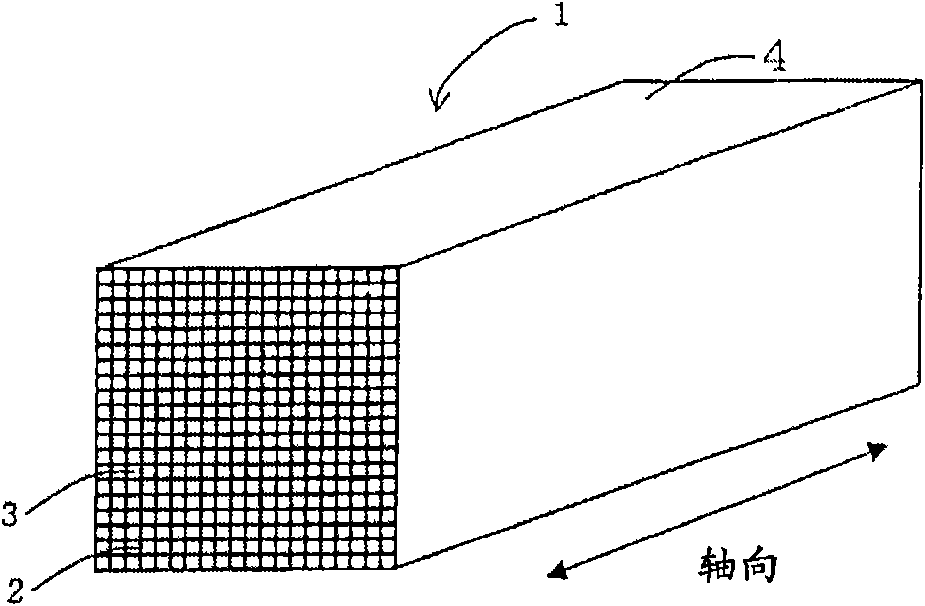

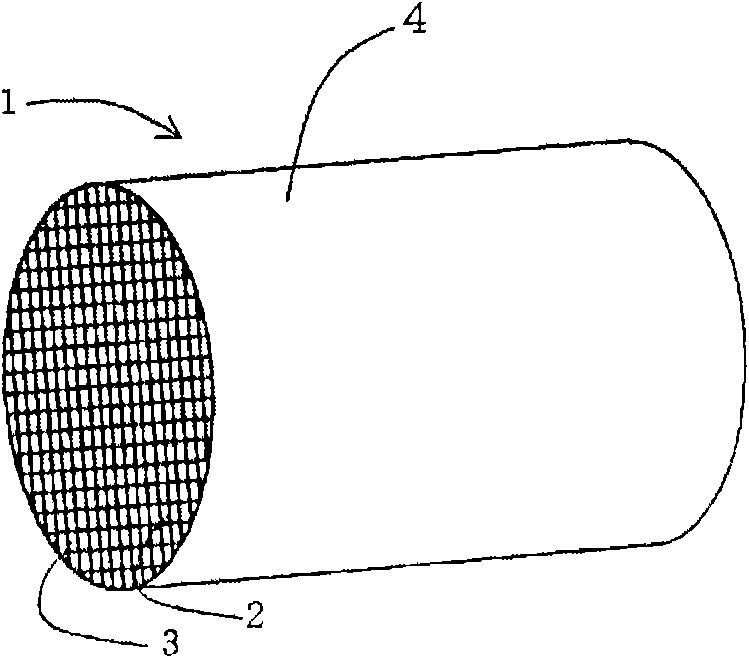

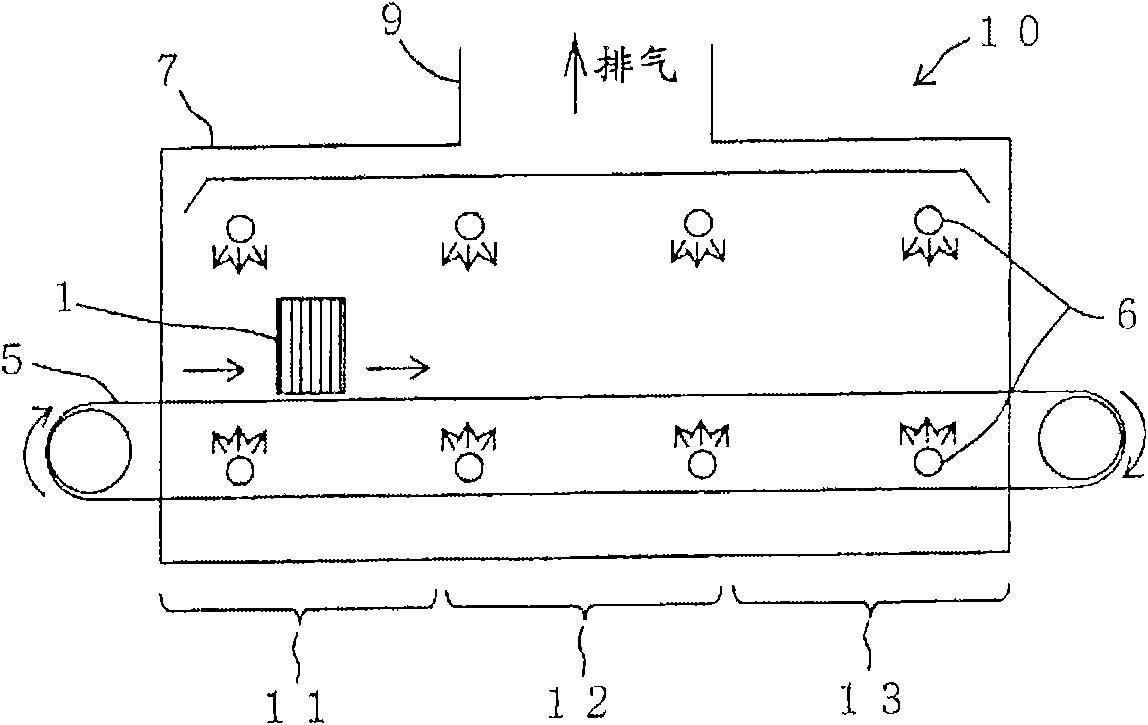

[0100] Prepare figure 2 The honeycomb molded body 1 (outer diameter x flow path length: 80mm x 100mm, cell density: 50 cells / cm 2 , Partition wall thickness: 0.3mm). For prepared honeycomb moldings, use image 3 In the continuous processing apparatus 10 having the configuration shown, pre-firing treatment (drying) was performed under the conditions shown in Table 1. Here, the lengths in the traveling direction of the zone (1) 11, the zone (2) 12, and the zone (3) 13 in the continuous processing apparatus 10 are 1.0 m, 1.0 m, and 1.0 m, respectively. In addition, the conveying speed in the continuous processing apparatus 10 was 0.33 m / min. Table 1 shows the mass (initial mass (g)) before the firing pretreatment of the honeycomb formed body, the mass (g) after the treatment, and the mass reduction rate (%). In addition, in Figure 5 Shows a graph plotting the relationship between superheated steam temperature (region (2)) (°C) and mass reduction rate (%). As shown in Tabl...

Embodiment 9~12

[0108] A honeycomb formed body (dried body) (outer diameter x flow path length: 150 mm x 200 mm) obtained by drying under the same conditions as in Example 3 except that the treatment time was 40 mm was prepared. The prepared honeycomb formed body was subjected to pre-firing treatment (degreasing) under the conditions shown in Table 3. Table 3 shows the mass (initial mass (g)) before the firing pretreatment of the honeycomb formed body, the post-treatment mass (g), and the mass reduction rate (%). In addition, in Image 6 Represents a graph plotting the relationship between superheated steam temperature (°C) and mass reduction rate (%). As shown in Table 3, regardless of the conditions, the mass of the treated honeycomb formed body decreased, and its color changed from white to gray. In addition, the honeycomb formed body obtained by processing under the conditions of Examples 9 and 10 was in a slightly brittle state, and a certain amount of care was required in handling. O...

Embodiment 13

[0112] Prepare figure 2 Honeycomb molded body with the shape shown, made of ceramic raw materials and binders and other molding aids (outer diameter x flow path length: 113mm x 210mm, cell density: 93 cells / cm 2 , Partition wall thickness: 0.1mm). For prepared honeycomb moldings, use Figure 7 with Figure 8 The drying device 21 of the honeycomb formed body of the shown configuration performs drying. Here, the superheated steam inlet 25 provided in the lower part of the honeycomb formed body 41 is not used. Microwaves with a frequency of 2.45 GHz were irradiated for 300 seconds at an output density of 5 kW / kg. The temperature of the superheated steam atmosphere in the processing chamber 22 was 130°C. In addition, the conveying speed of the belt conveyor 28 was 0.32 m / min. For the honeycomb formed body in the drying process, the temperature change was measured at the center point A (inner A) of the upper end surface and the position B (peripheral portion B) at 10 mm from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com