Process for aging meat duck after butchering

A processing technology, meat duck technology, applied in the direction of processed meat, poultry processing, slaughtering, etc., can solve the problem of low proportion of deacidified livestock meat, etc., and achieve the effects of improving eating quality, water retention, and absorption utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

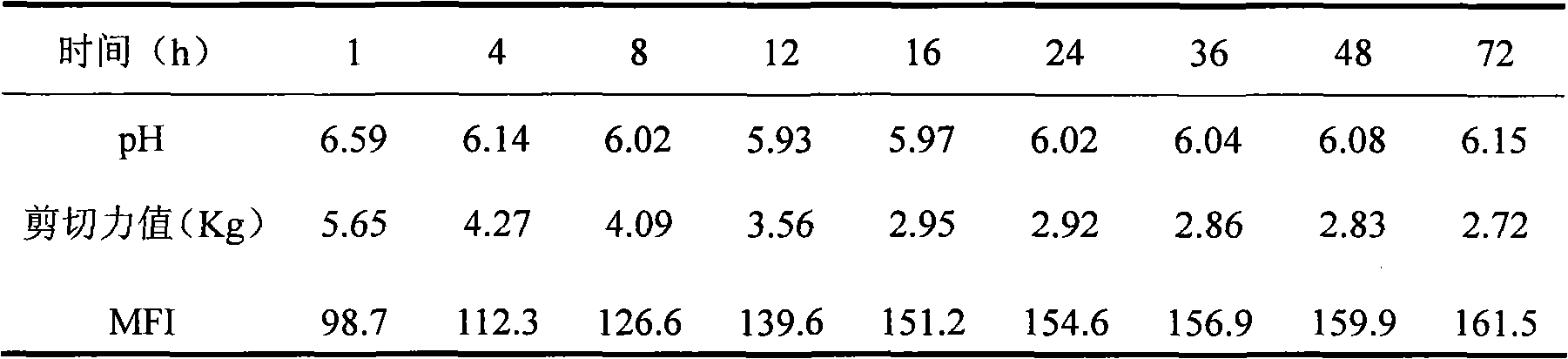

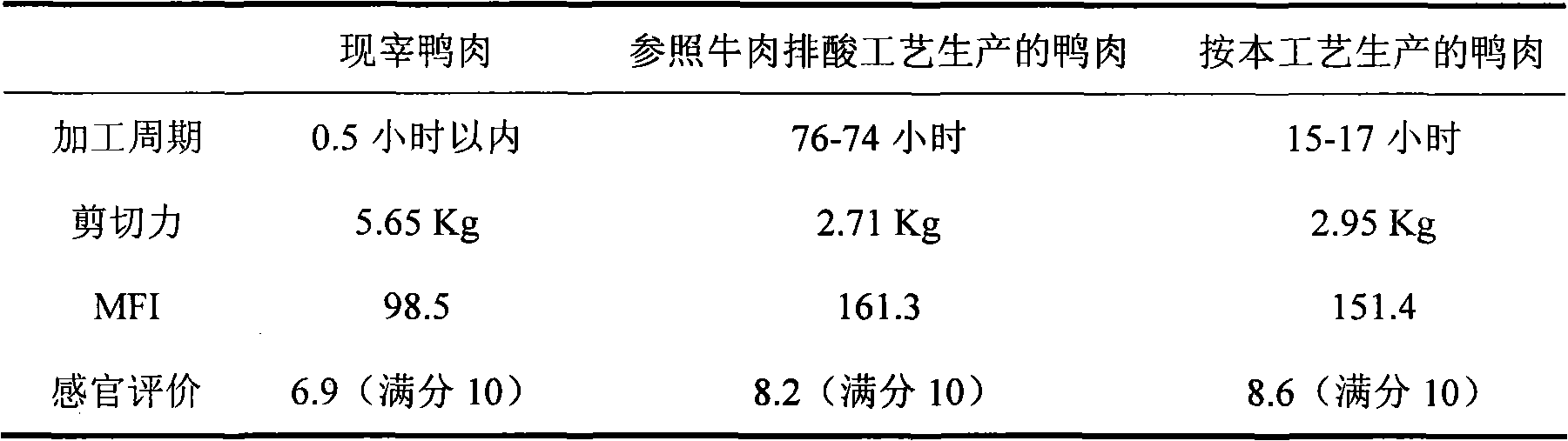

Embodiment 1

[0027] Sheldon ducks with an individual gross weight of 2.5-3.0kg are selected, and the raw ducks are slaughtered, bled, depilated, eviscerated, and the tail is removed to obtain bare ducks. Wash the blood and debris on the surface, hang and drain for 40 minutes, and place it in a pre-cooling workshop at 10°C for 30 minutes; pass the bare duck through the spray tunnel through the rotary rail, use an atomizing nozzle, and use 1.5% lactic acid solution (water temperature 10°C) Spray evenly on the surface of the bare duck (about 10 minutes). After spraying, it is directly transported to the acid discharge workshop; the acid discharge is carried out in two stages. The first stage: the workshop temperature is 7°C, the humidity is 75%, and the time is 2 hours. The second stage: the workshop temperature is 4°C, the humidity is 90%, and the time is 14 hours; after acid discharge, it can be divided (the temperature of the divided workshop is 6°C), after vacuum packaging, refrigerated st...

Embodiment 2

[0029] Muscovy ducks with an individual gross weight of 3.5-4.0kg are selected, and the raw ducks are slaughtered, bled, depilated, eviscerated, and the tail is removed to obtain bare ducks. Wash the blood and debris on the surface, hang and drain for 40 minutes, and place it in a pre-cooling workshop at 10°C for 30 minutes; pass the bare duck through the spray tunnel through the rotary rail, use an atomizing nozzle, and use 1.5% lactic acid solution (water temperature 10°C) Spray evenly on the surface of the bare duck (about 10 minutes). After spraying, it is directly transported to the acid discharge workshop; the acid discharge is carried out in two stages. The first stage: the workshop temperature is 8°C, the humidity is 73%, and the time is 3.0 hours. The second stage: the workshop temperature is 4°C, the humidity is 85%, and the time is 14 hours; after acid discharge, it can be divided (the division workshop temperature is 6°C), after vacuum packaging, refrigerated storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com