Vanadium titano-magnetite flotation method

A technology of vanadium-titanium magnetite and vanadium-titanium magnet, which is applied in flotation, solid separation, etc., and can solve problems such as excessive sulfur and phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

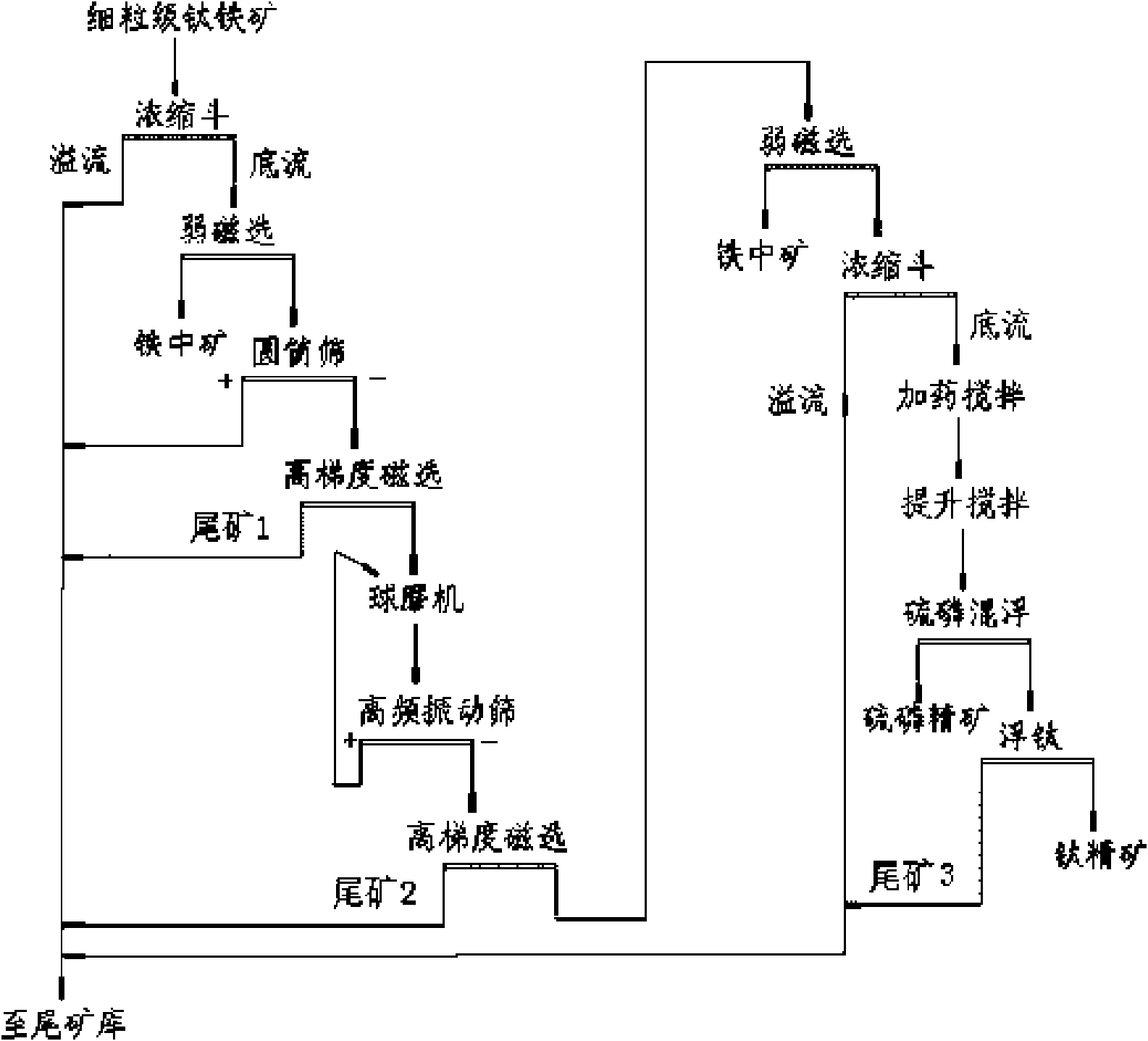

Image

Examples

Embodiment 1

[0018] TiO 2 100 tons of fine-grained vanadium-titanium magnetite (-200 mesh, 55%) with a content of 8.5% (wt), after settling in the thickening hopper, 10 tons of mud overflowed, and 90 tons of underflow passed through a 1200Gs weak magnetic separator for magnetic separation Obtain 3t of iron medium ore with a TFe content of 35%. After the remaining ore is screened through a cylindrical sieve, the obtained 86t of undersize is sent to the first stage of high gradient magnetic separator for magnetic separation to obtain tailings 1 and 68t of TiO 2 The magnetically separated ilmenite with a content of 13% is subjected to closed-circuit grinding and screening by a ball mill and a high-frequency vibrating screen, and the undersieve is sent to the second stage of high-gradient magnetic separator for magnetic separation to obtain tailings 2 and 34t TiO 2 The magnetically separated ilmenite with a content of 20% is magnetically separated by a 1200Gs weak magnetic separator to obtain...

Embodiment 2

[0021] TiO 2 100 tons of fine-grained vanadium-titanium magnetite (-200 mesh, 55%) with a content of 9.0% (wt), after being concentrated in a thickening hopper, 10 tons of mud will overflow, and 90 tons of underflow will pass through a 1200Gs weak magnetic separator for magnetic separation Obtain 3t of iron ore with a TFe content of 35%. After the remaining ore is sieved through a cylindrical sieve, the obtained 86t of undersieve enters the first stage of high gradient magnetic separator for magnetic separation to produce 70t of TiO 2 The magnetically separated ilmenite with a content of 13% is subjected to closed-circuit grinding and screening by a ball mill and a high-frequency vibrating screen, and the underscreen material enters the second stage of high-gradient magnetic separator for magnetic separation to produce 36t TiO 2 Magnetically separated ilmenite with a content of 20% is magnetically obtained by a 1200Gs weak magnetic separator to obtain 1t of iron ore, and the r...

Embodiment 3

[0024] TiO 2 100 tons of fine-grained vanadium-titanium magnetite with a content of 9.5% (wt) (-200 mesh accounts for 60%), after being concentrated in a thickening hopper, 10 tons of mud is overflowed, and 90 tons of bottom flow is magnetically separated by a 1200Gs weak magnetic separator Obtain 3t of iron ore with a TFe content of 35%. After the remaining ore is sieved through a cylindrical sieve, the obtained 86t of undersize enters the first stage of high-gradient magnetic separator magnetic separation to produce 73t of TiO 2 The magnetically separated ilmenite with a content of 13% is subjected to closed-circuit grinding and screening by a ball mill and a high-frequency vibrating screen, and the underscreen material enters the second stage of high-gradient magnetic separator for magnetic separation to produce 39t TiO 2 The magnetically separated ilmenite with a content of 20% is magnetically separated by a 1200Gs weak magnetic separator to obtain 1t of iron ore, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com