Method for preparing medical high-activity silicon oil

A high-activity, silicone oil technology, applied in the field of medical high-activity silicone oil preparation, can solve the problems of inability to meet the biological performance requirements of medical devices, poor surface adhesion of medical devices, poor sliding performance, etc., to achieve improved lubrication performance and low cost , Improve the effect of lubricating performance and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

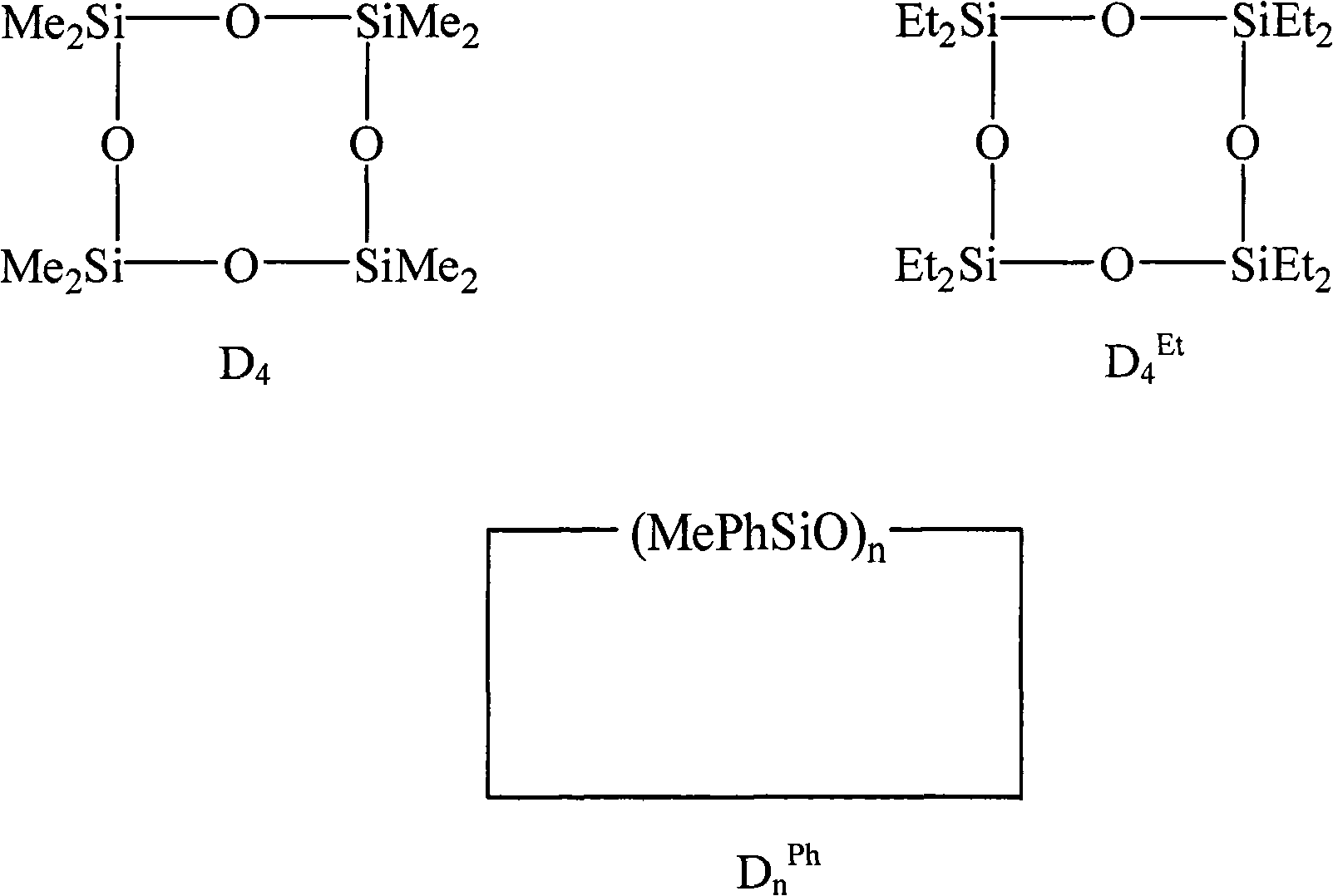

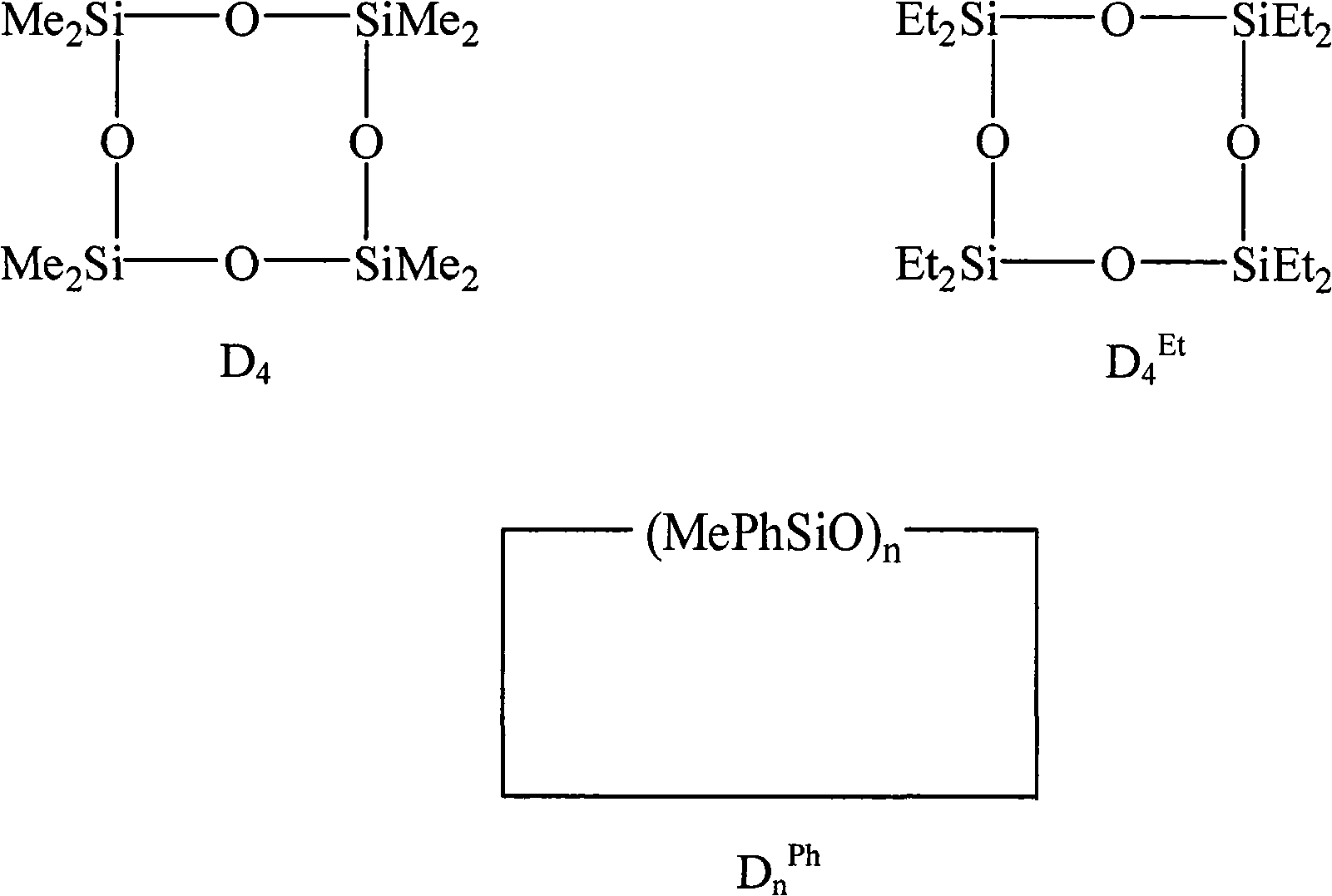

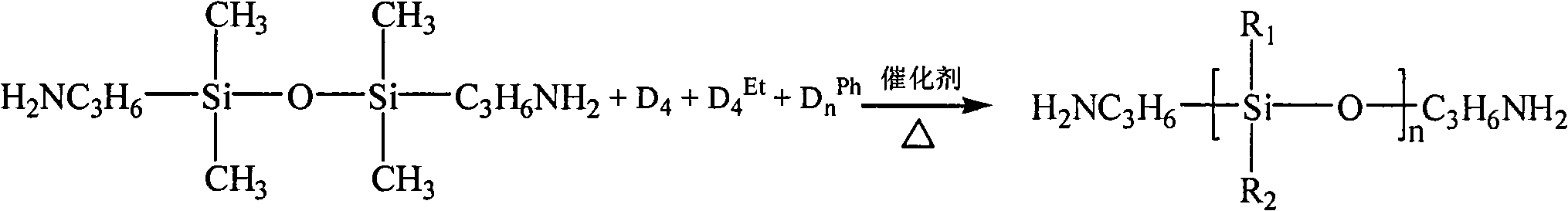

Method used

Image

Examples

Embodiment 1

[0030] in N 2 Under protection, add 21.9g of polymerized monomers to a 500mL dry three-necked bottle D 4 , 32.6g D 4 Et , 54.5g D n Ph , 6.0g aminopropyl tetramethyldisiloxane, 1.8g (CH 3 ) 4 NOH and 15g of cyclohexyl-18-crown-6 (cyclic polyether) were injected with high-purity nitrogen gas for 20 minutes and stirred and mixed uniformly. Under the condition of 30-40°C / 0.095MPa, use ultrafiltration equipment equipped with modified polysulfone ultrafiltration membrane to remove particulate impurities and heat sources in the material. Control the reaction temperature of the mixed liquid at 100°C, polymerize for 3 hours, then raise the temperature to 180°C to degrade the catalyst, and reduce the pressure to 0.095MPa to remove low molecular weight compounds. Cool to 50°C, add 0.6g aminopropyltriethoxysilane, 0.3g aminopropyltrimethoxysilane and stir for 1h, cool to room temperature, the product is colorless and transparent medical high-activity silicone oil, viscosity (25°C)...

Embodiment 2

[0032] Adopt the method identical with embodiment 1, with 19.8g D 4 , 28.5g D 4 Et , 51.7g D n Ph , 8.0g aminopropyl tetramethyldisiloxane, 1.5g (CH 3 ) 4 NOH and 12g of cyclic polyether were reacted at 90°C for 2h, after the polymerization and treatment were completed, the viscosity of the obtained highly active medical silicone oil was 10000mpa.s.

Embodiment 3

[0034] Adopt the method identical with embodiment 1, with 25.6gD 4 , 36.8gD 4 Et , 37.6gD n Ph , 4.0g aminopropyl tetramethyldisiloxane, 1.2g (CH 3 ) 4 NOH and 17g of cyclic polyether were reacted at 110°C for 2 hours. After the polymerization and treatment were completed, the obtained highly active medical silicone oil had a viscosity of 20,000mpa.s.

[0035] Application Test and Results

[0036] 1. Source of test samples

[0037] According to the embodiment of the product of the present invention, the medical high-activity silicone oil produced

[0038] 2. Siliconized disposable syringe barrel test:

[0039] 2.1 Siliconized 20ml syringe dilution ratio:

[0040] Solvent: medical high active silicone oil=100g: 10g

[0041] 2.2 Siliconization method: spraying

[0042] 2.3 Comparison of test results with national standards:

[0043] Syringe

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com