Method for monitoring steel bar corrosion state in concrete by stages and sensor

A steel corrosion and concrete technology, applied in transmittance measurement, phase influence characteristic measurement, optical test flaws/defects, etc., can solve the problem that the corrosion state of steel bars cannot be truly reflected, so as to overcome the influence of unstable light source and prolong the effective working time. , the effect of ensuring reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

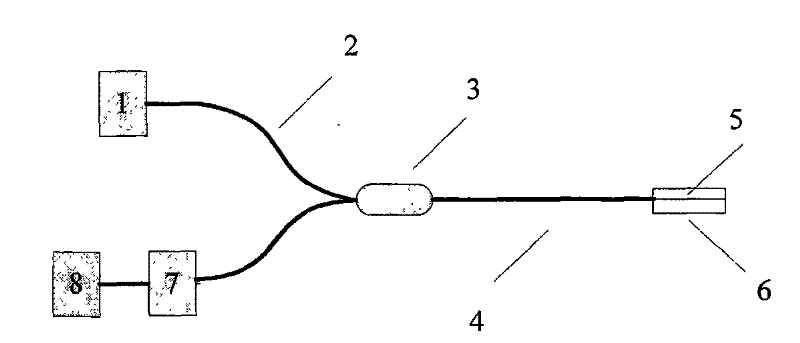

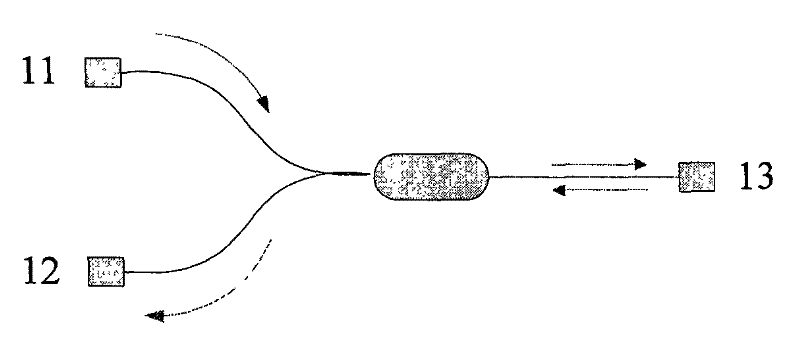

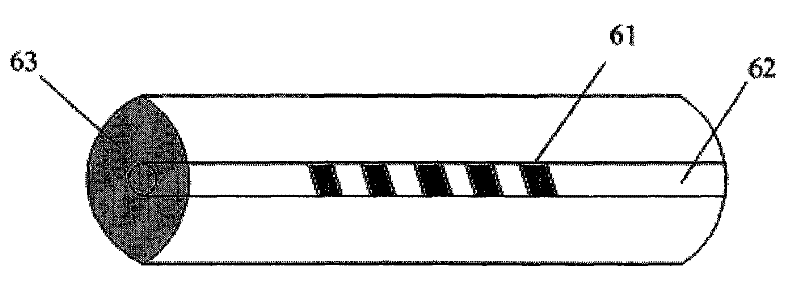

[0031] Depend on figure 1 It can be seen that the concrete composition of the long-period fiber grating steel bar corrosion sensor system of the present invention is that broadband light source 1 (can adopt LG150 type broadband light source), enters Y-type fiber coupler 2 (such as figure 2 shown) to the input end of the Y-type fiber coupler 2, and then through the coupler joint 3, through the sensing fiber 4 to the terminal reflective long-period fiber grating steel bar corrosion sensor probe 5, and the environment to be measured in Cl - The content interaction produces the coupling effect between the core and the cladding, and after passing through the reflective metal film on the end face of the core in the probe 5, the reflected light is formed and enters the spectrometer 7 through the reflective end of the Y-shaped fiber coupler 2 (AQ6317 spectrometer can be used ), and then processed by the computer 8 to output the relationship curve between the reflected light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com