Method for producing ONO structure

A wet etching and oxide film technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as poor etching uniformity, photoresist peeling, and increase in size, and achieve control of lateral etching. etch, eliminate peeling problems, improve window performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

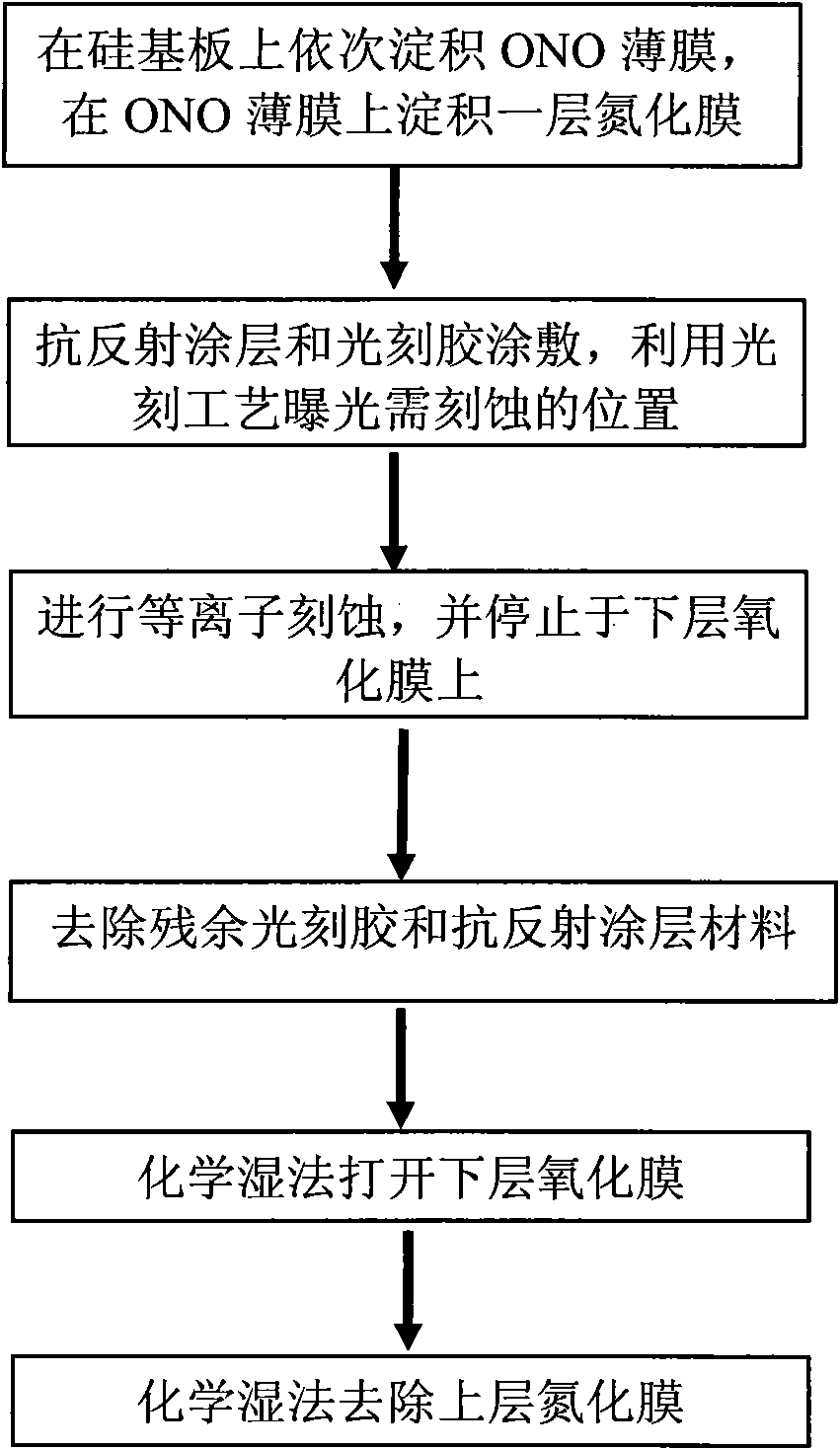

[0022] In order to avoid stripping of the photoresist, the present invention uses a nitride film as a hard mask layer in the last step of etching the oxide film. After all the patterns are defined, the nitride film layer is stripped off to form an ONO structure. Process flow of the present invention such as figure 2 shown.

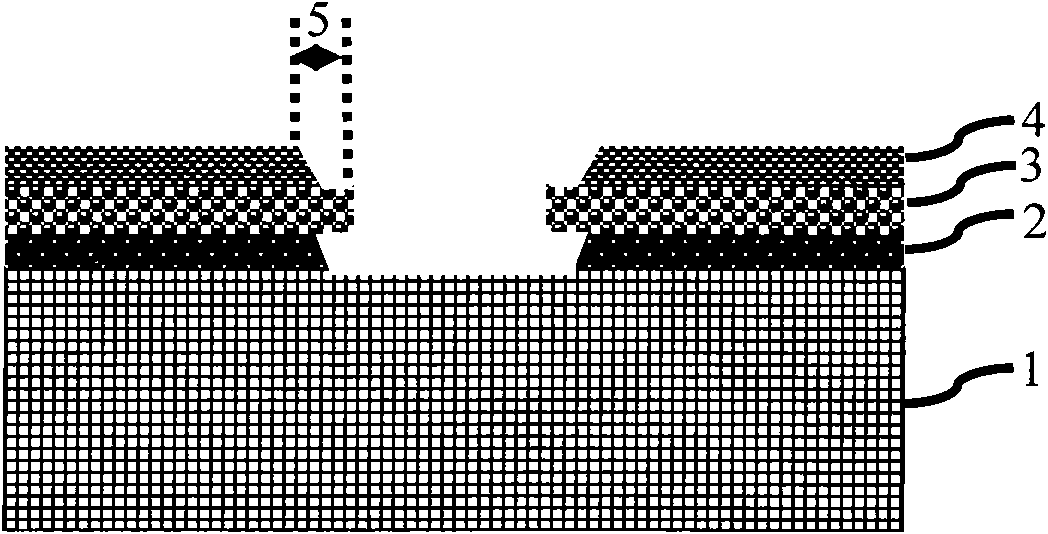

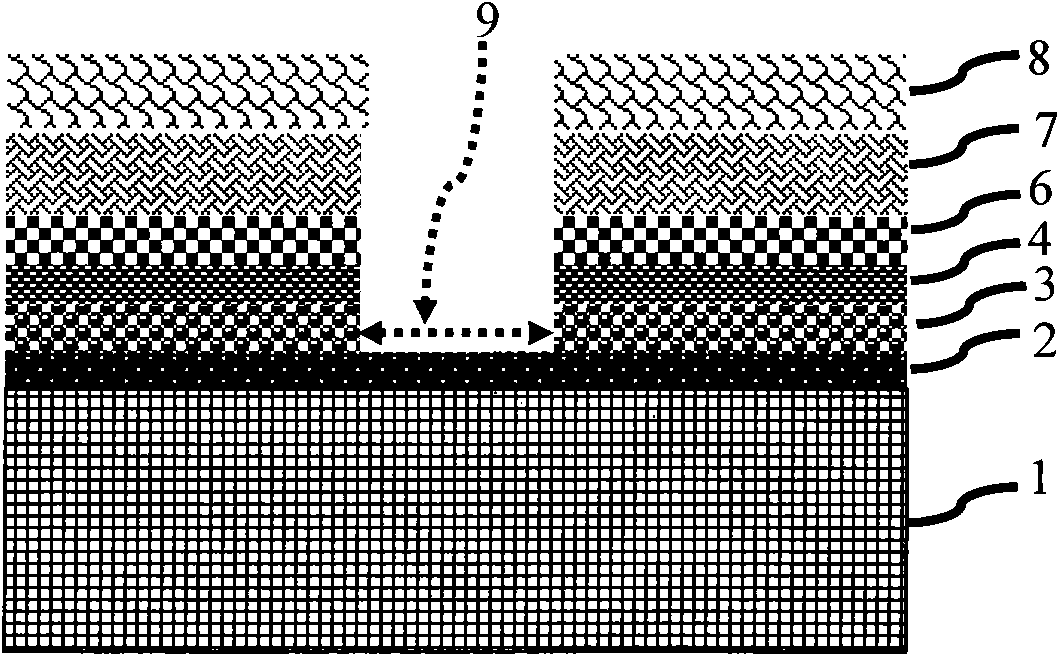

[0023] In the first step, the lower oxide film 2 , the middle oxide nitride film 3 , the upper oxide film 4 and the nitride film 6 are grown sequentially on the silicon substrate 1 . When NONO is grown, the thickness of the nitride film 6 should be less than 200 angstroms, so as to reduce inter-film stress and shorten the final removal time of the nitride film.

[0024] In the second step, the pattern on the photomask is transferred into the photoresist 8 by photolithography. In order to make up for the loss of size 5 caused by the subsequent etching process and chemical wet process, the line size will be compensated during photolithography. After expo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com