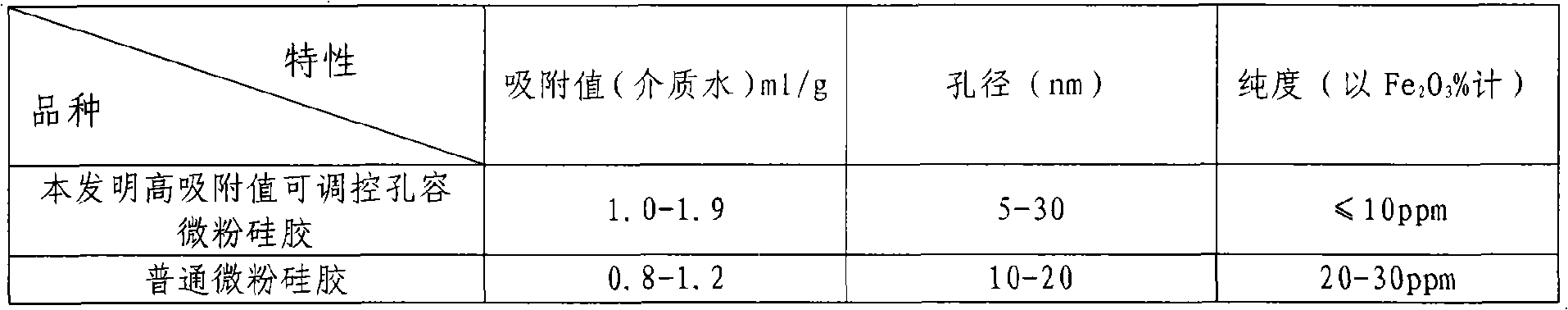

Method for preparing superfine silica gel powder with high adsorptive value and adjustable pore volume

A technology of micropowder silica gel and high adsorption, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as unstable quality, high price, poor performance of micropowder silica gel, achieve single pore size distribution, increase adsorption value, The effect of uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0018] The preparation method is specifically as follows: add a certain amount of additives to the sulfuric acid solution with a concentration of 22% as required, pour it into the acid metering tank, add a certain amount of additives to the sodium silicate solution with a concentration of 18% as required, and pour it into the acid metering tank. Put the two solutions into the alkali metering tank, pass the two kinds of solutions through the conventional granulation equipment, and under the pressure of 0.5MPa, synthesize and react at the temperature of 45-55°C to form gel particles. Add aging agent at a ratio of 1:100, and perform aging at a temperature of 35-45°C. The aging time is 3-6 hours. The temperature is 35-45°C, and the acid treatment time is 3-5 hours. After the acid treatment, the acid treatment solution is released, poured into 70-80°C water and washed 5 times in a string of four. After washing, put the gel particles into the The drying tunnel is used for drying, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com