Worm-wheel stroke internal combustion engine

An internal combustion engine and turbine technology, applied in combustion engines, engine components, machines/engines, etc., can solve the problems of accelerating component wear, affecting engine service life, and high energy consumption, improving energy conversion rate, avoiding high-frequency jitter, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

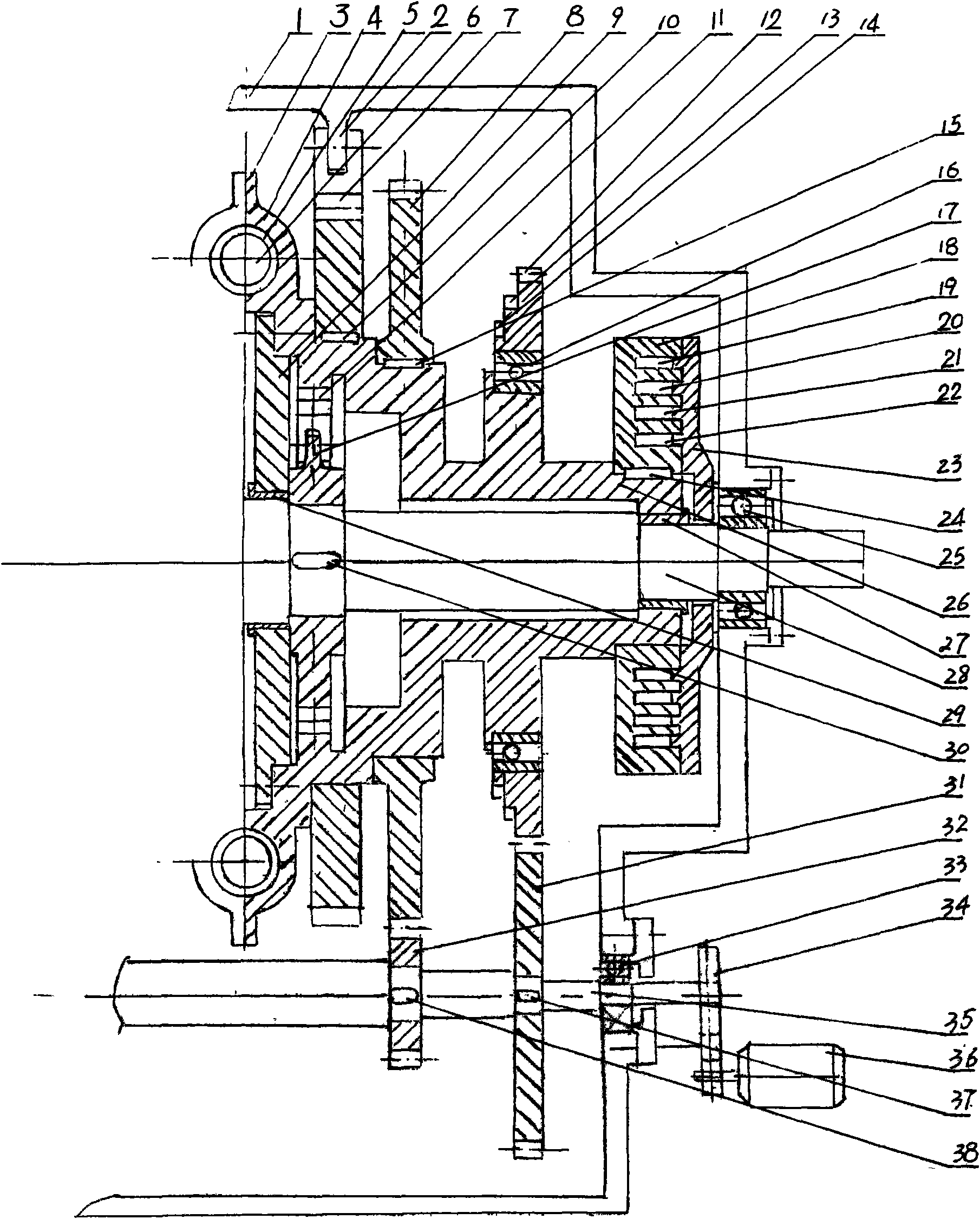

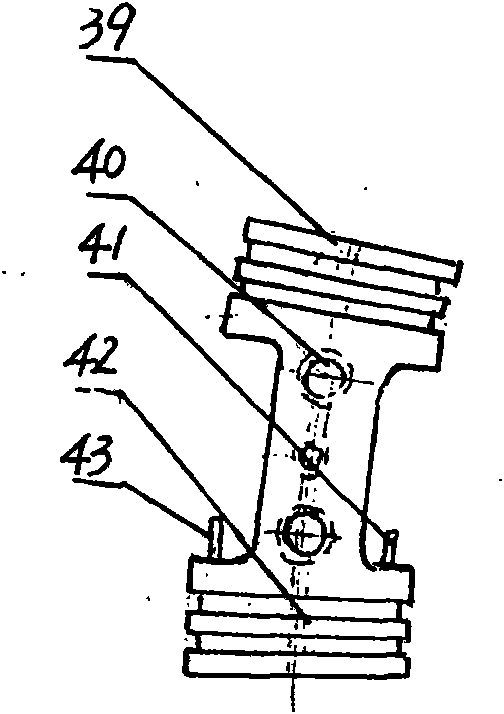

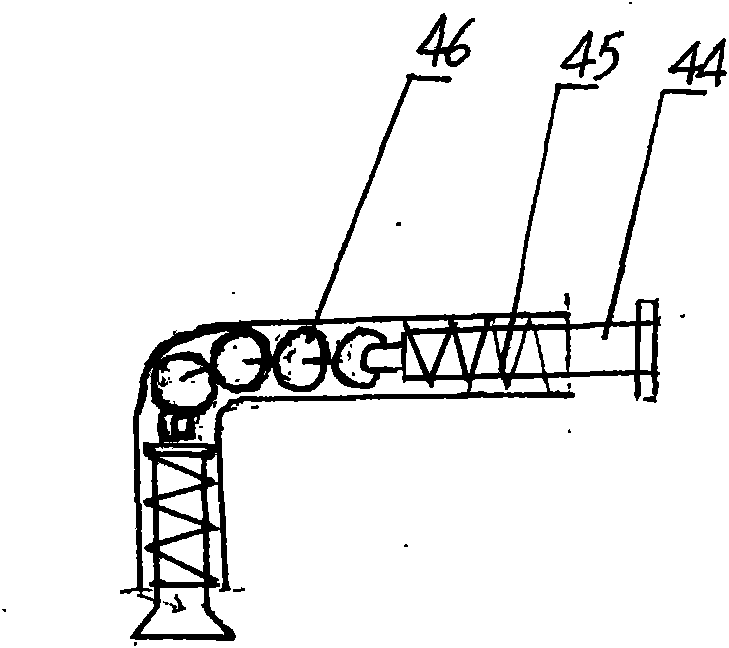

[0012] like Figure 1 to Figure 3 As shown, the present invention includes body shell 1, cylinder block 4, 5, cylinder head 6, transmission component connecting member and oil, water, gas supply pipe and exhaust pipe, is characterized in that two symmetrical semi- Body, two half bodies are connected through the main shaft 28, and the underside of the half body is provided with an auxiliary shaft 35 parallel to the main shaft. On the auxiliary shaft, a middle gear 31 meshing with the main shaft gear 12 and an arc gear 31 are bonded by keys 37 and 38. The pinion 32 meshed with the shaped ratchet gear 8, the so-called arc ratchet gear is provided with tooth segments in sections, and the number of tooth segments depends on the number of cylinder heads. For example, four cylinder heads are four sections, and eight cylinder heads are eight sections. Sections, and so on, the main and auxiliary shafts are socketed with the body shell through bearings 25, 33, and the outer end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com