High-precision drive and control integration motor

A high-precision, controller technology, applied in the direction of controlling mechanical energy, using feedback control, electromechanical devices, etc., can solve the situation of strong impact and strong vibration, without considering the influence of the control accuracy of the deceleration mechanism, and it is difficult to meet the industrial control environment. and other problems, to achieve the effect of suppressing backlash nonlinearity, high integration, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

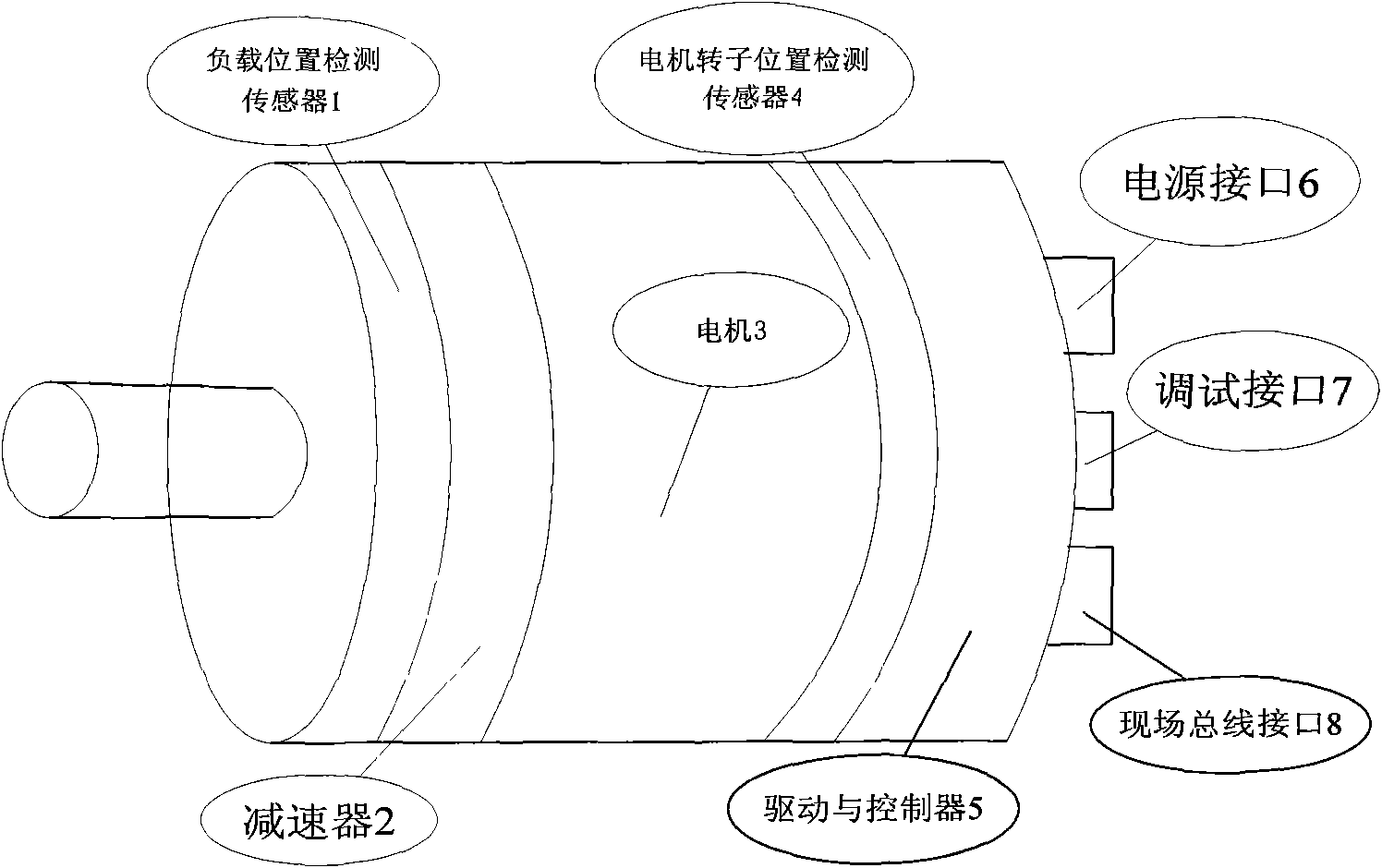

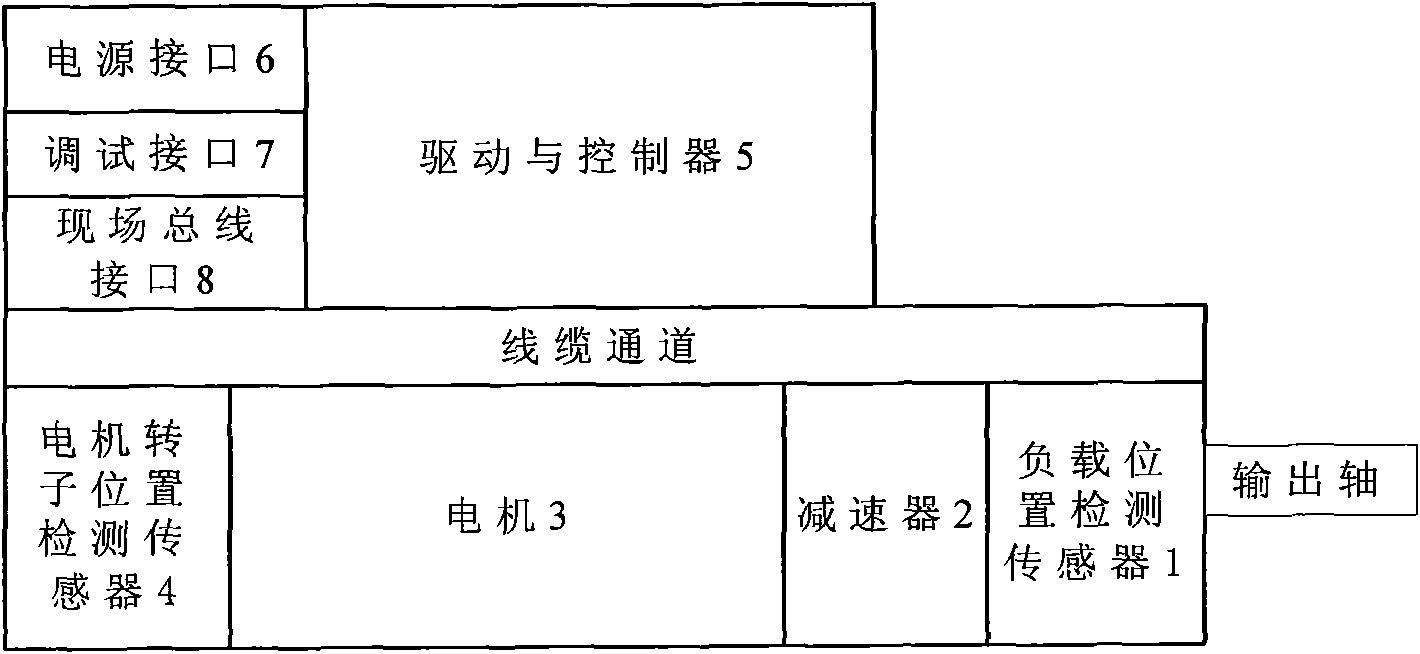

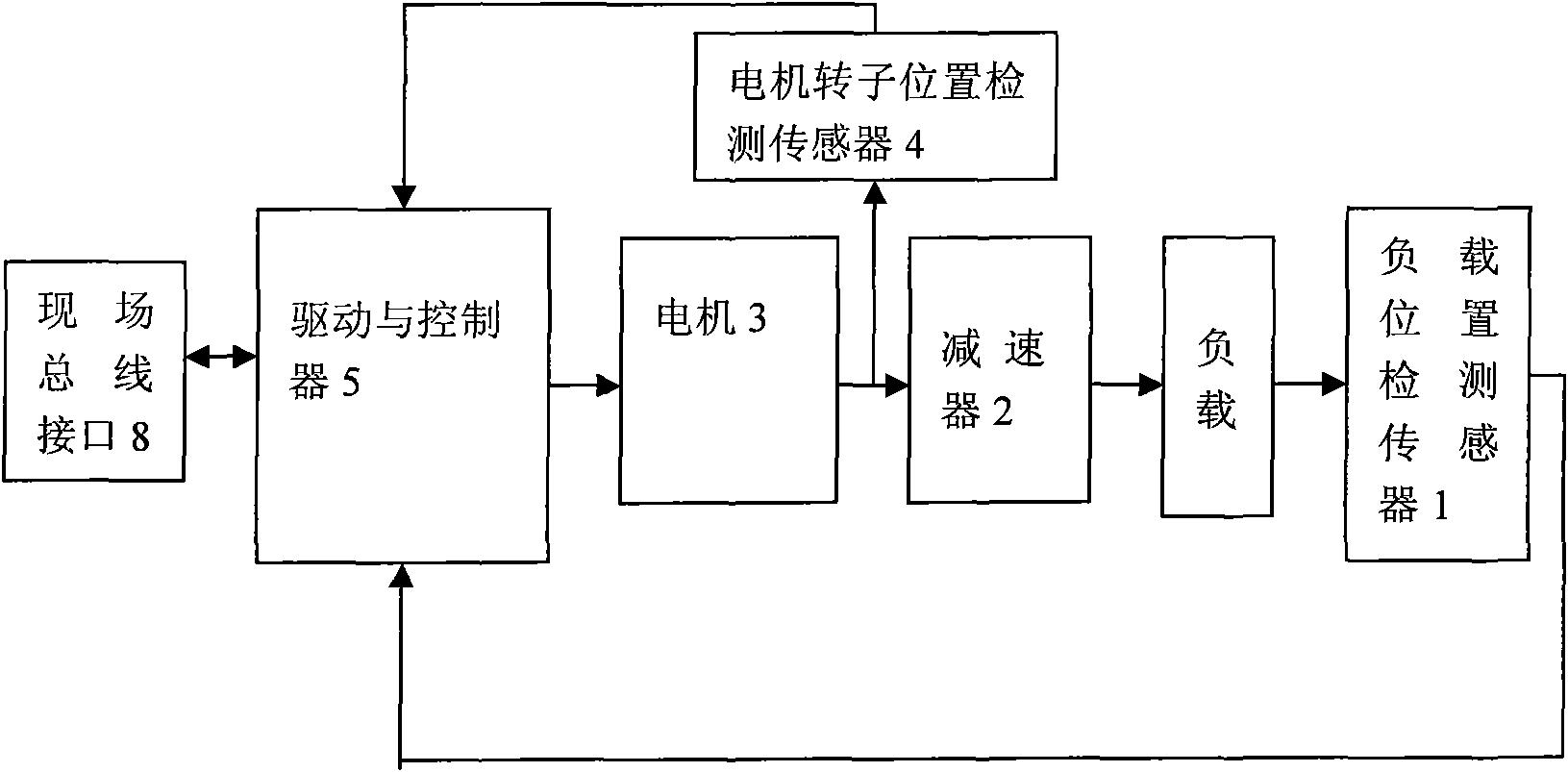

[0019] to combine figure 1 and figure 2 , the high-precision drive and control integrated motor of the present invention includes a power interface 6, a load position detection sensor 1, a reducer 2, a motor 3, a motor rotor position detection sensor 4, a debugging interface 7 connecting the drive and the controller 5, and the on-site The bus interface 8 is integrated, that is, the output shaft connected to the load position detection sensor 1 is directly connected to the load, and the two sides of the motor 3 are respectively coaxially connected to the motor rotor position detection sensor 4 and the reducer 2. The load position detection sensor 1 and The load is coaxially installed, and the signals of the load position detection sensor 1 and the motor rotor position detection sensor 4 are led to the drive and controller 5 by shielded wires.

[0020] The motor 3 is a high-performance, maintenance-free AC permanent magnet synchronous motor or servo motor, which has the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com