Sealing tooth staggered type squeeze oil film damper

A technology of extruding oil film damping and sealing teeth, which is applied in the direction of liquid shock absorber, spring/shock absorber, vibration suppression adjustment, etc., can solve the problem of stable and reliable working open damper, underutilized axial length, design and high manufacturing difficulty, to achieve full utilization of the axial length, good sealing effect, and improved damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Since the structural parameters such as the shape and quantity of the sealing teeth vary with the actual situation, in order to facilitate a clear understanding of the present invention, the sealing teeth whose shape is an isosceles triangle are given as examples below for illustration.

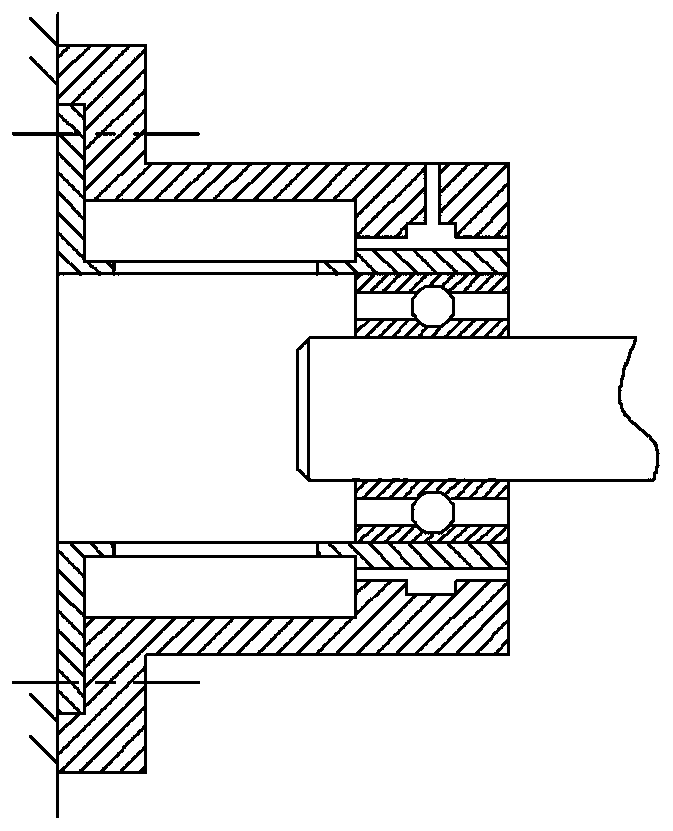

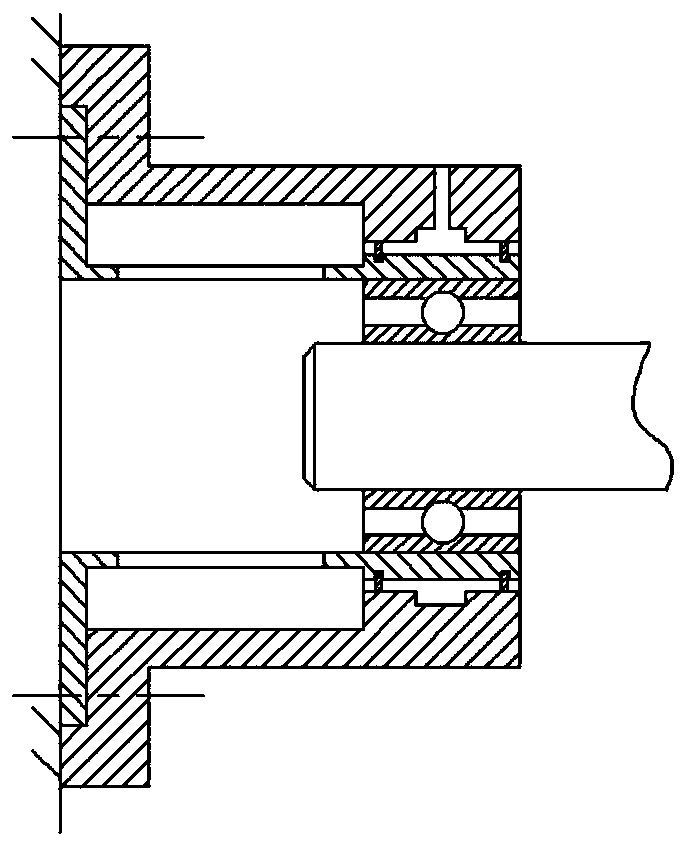

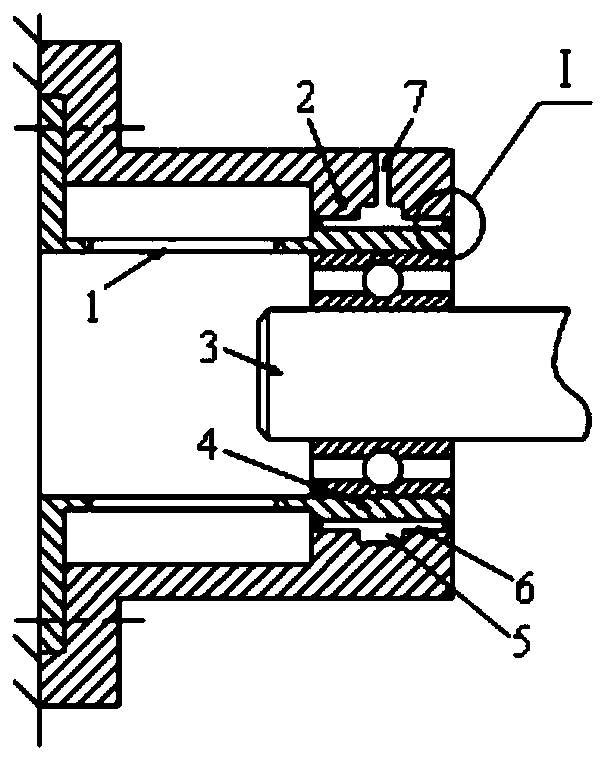

[0041] A staggered seal tooth squeeze oil film damper, its structure schematic diagram is as follows image 3 shown. The head of the elastic support 1 is used as the inner ring of the damper 4, and the inner ring of the bearing housing is used as the outer ring of the damper 2, and the two are in clearance fit. Lubricating oil is injected into the gap through the oil supply hole 7 and the oil supply groove 5 to form an oil film 6 . The schematic diagram of the local structure of part I is as follows: Figure 4 As shown, the two ends of the damper inner ring 4 and the damper outer ring 2 are processed inner ring sealing teeth 9 and outer ring sealing teeth 8, both of which are isoscel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com