New preparation technology and new applications of syringa amurensis rupr bar extract components

A technology of extracting and extracting Martini, which is applied in botany equipment and methods, medical preparations containing active ingredients, chemicals for biological control, etc., can solve the problem of anti-inhibiting components of unexploded Martini bark extract Bacteria research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Take 5kg of the bark of Cinnamon chinensis, pick out the sundries, wash with water, dry or dry in the air, pulverize, extract with 8 times the amount of 10% ethanol at room temperature for 10h, and then ultrasonic for 1h, the temperature is 30°C and the power is 80W, then filter once with silk cloth and filter paper to obtain the filtrate;

[0020] (2) The filter residue of the bark of Cinnamomum chinensis after (1) treatment repeats (1) step each once with 8 times of amount and 6 times of amount of 10% ethanol respectively, obtains filtrate respectively, merges three times of filtrate;

[0021] (3) The above-mentioned (2) filtrate is reclaimed ethanol to obtain the bark extract of Cinnamon chinensis, and the yield is 23%.

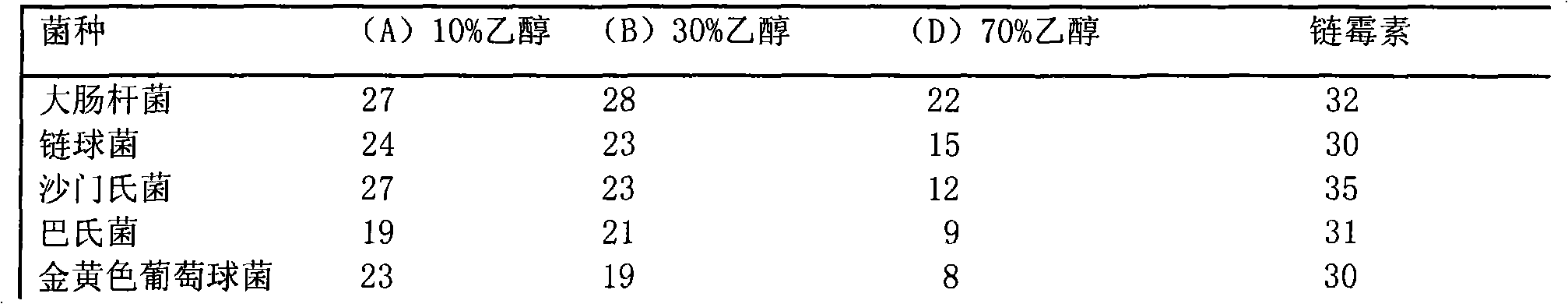

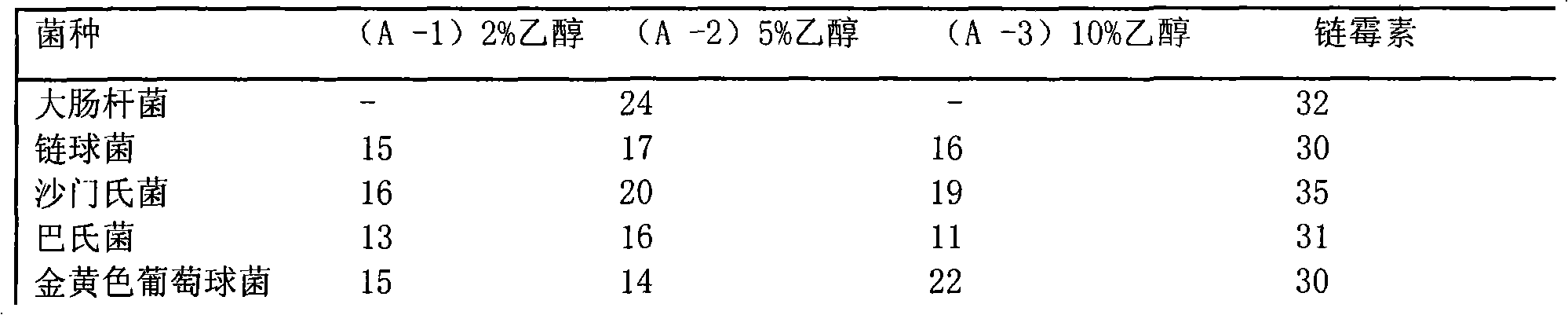

[0022] (4) the above-mentioned (3) bark extract of Pamarinosa bark, upper D 101 Too porous resin column, with H 2 O is eluted successively with 10%, 30%, 50%, and 70% ethanol after removing impurities to obtain macroporous resin ethanol elutio...

Embodiment 2

[0025] (1) Take 10kg of the bark of Cinnamon chinensis, pick out the sundries, wash with water, dry or dry in the air, pulverize, extract with 10 times the amount of 10% ethanol at room temperature for 12h, then ultrasonic for 1h, the temperature is 30°C and the power is 80W, then filter once with silk cloth and filter paper to obtain the filtrate;

[0026] (2) The filter residue after the treatment of the bark of Cinnamon chinensis through (1) repeats the steps of (1) once with 8 times of amount and 6 times of amount of 10% ethanol respectively, obtains the filtrate respectively, and merges the filtrate three times;

[0027] (3) Recover ethanol from the filtrate of (2) above to obtain the bark extract of Cinnamomum officinalis with a yield of 26%.

[0028] (4) the above-mentioned (3) bark extract of Pamarinosa bark, upper D 101 Macroporous resin column, with H 2 O is eluted successively with 10%, 30%, 50%, and 70% ethanol after removing impurities to obtain macroporous resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com