Air energy drying box

A technology of air energy drying and box door, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of high investment cost, large volume, equipment power consumption, energy consumption, etc., to reduce manufacturing costs, The effect of reducing equipment size and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

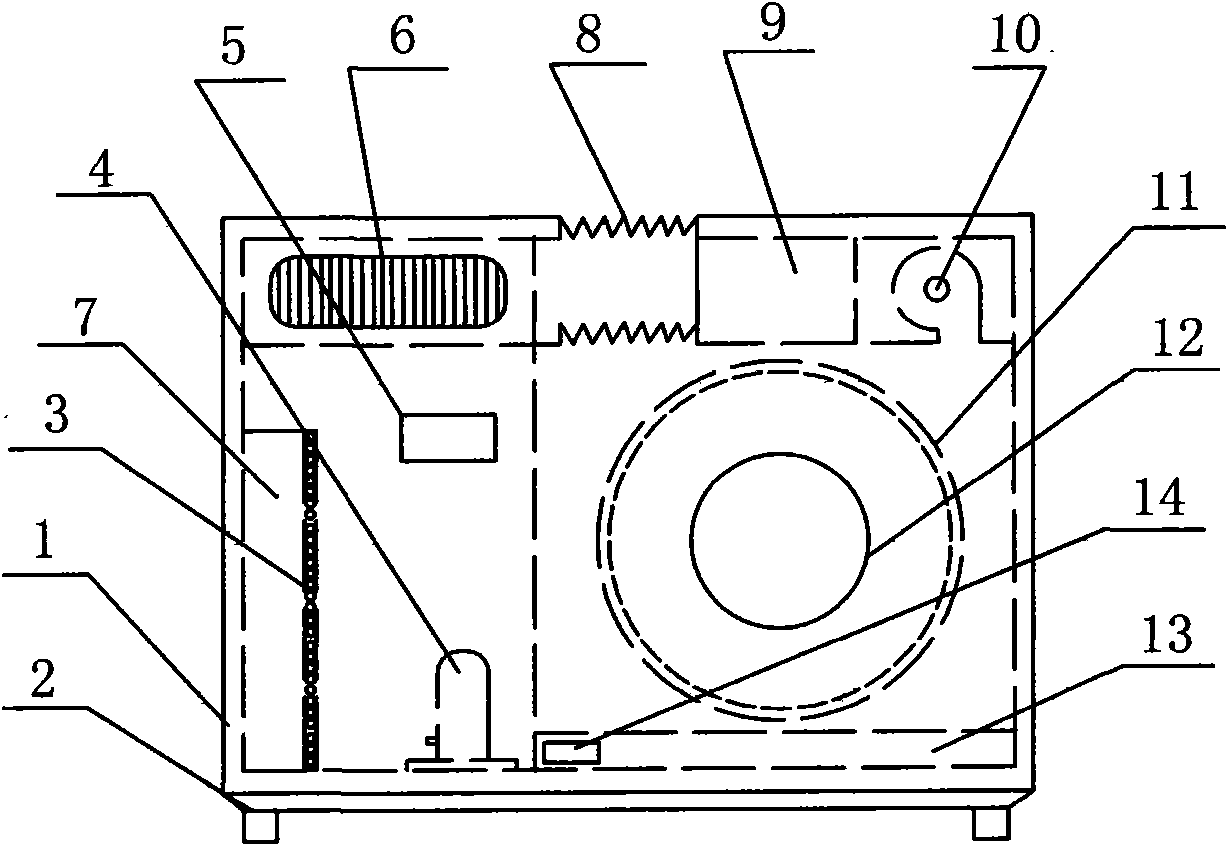

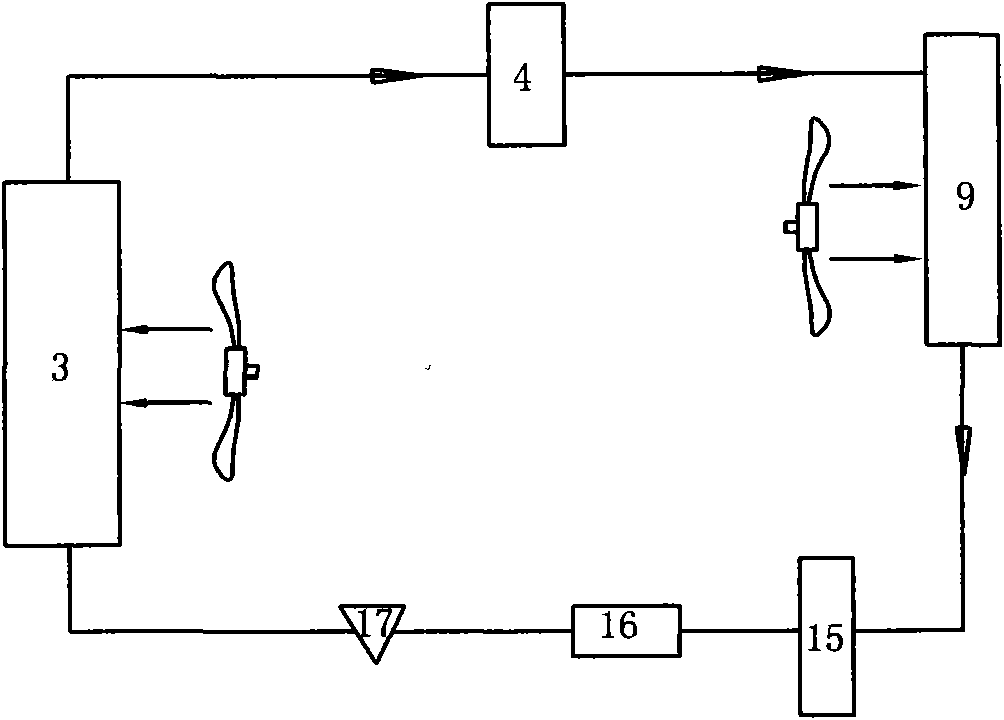

[0020] like figure 1 As shown, an air energy drying box includes a casing 1 and a base 2. A visible door 12 and a sewage and moisture discharge port 14 are arranged on one surface of the casing. The wheel 11 is provided with a dirt filter chamber 13 at the lower end of the rolling wheel, and the dirt filter cavity communicates with the sewage discharge and moisture discharge port 14; the heating system is arranged in the box body of the drying box, and the heating system is mainly composed of a compressor 4, an evaporator 3, a Heater 9, hot air blower 10, temperature control and humidity control electric air valve 8 and controller 5; the output end of evaporator 3 is connected with compressor 4, the output end of compressor 4 is connected with heat exchanger 9, and the heat exchanger The output end of 9 is connected to the evaporator 3, and a liquid reservoir, a filter and a throttling device are also arranged between the heat exchanger and the evaporator.

[0021] The casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com