Thermal power measurement device

A technology for measuring devices and thermal power, applied in the directions of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of large signal and error of the device, no temperature equalization system installed in the calorimetric device, and low accuracy of ambient temperature control, and achieve Effects of reduced position dependence, good contact, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

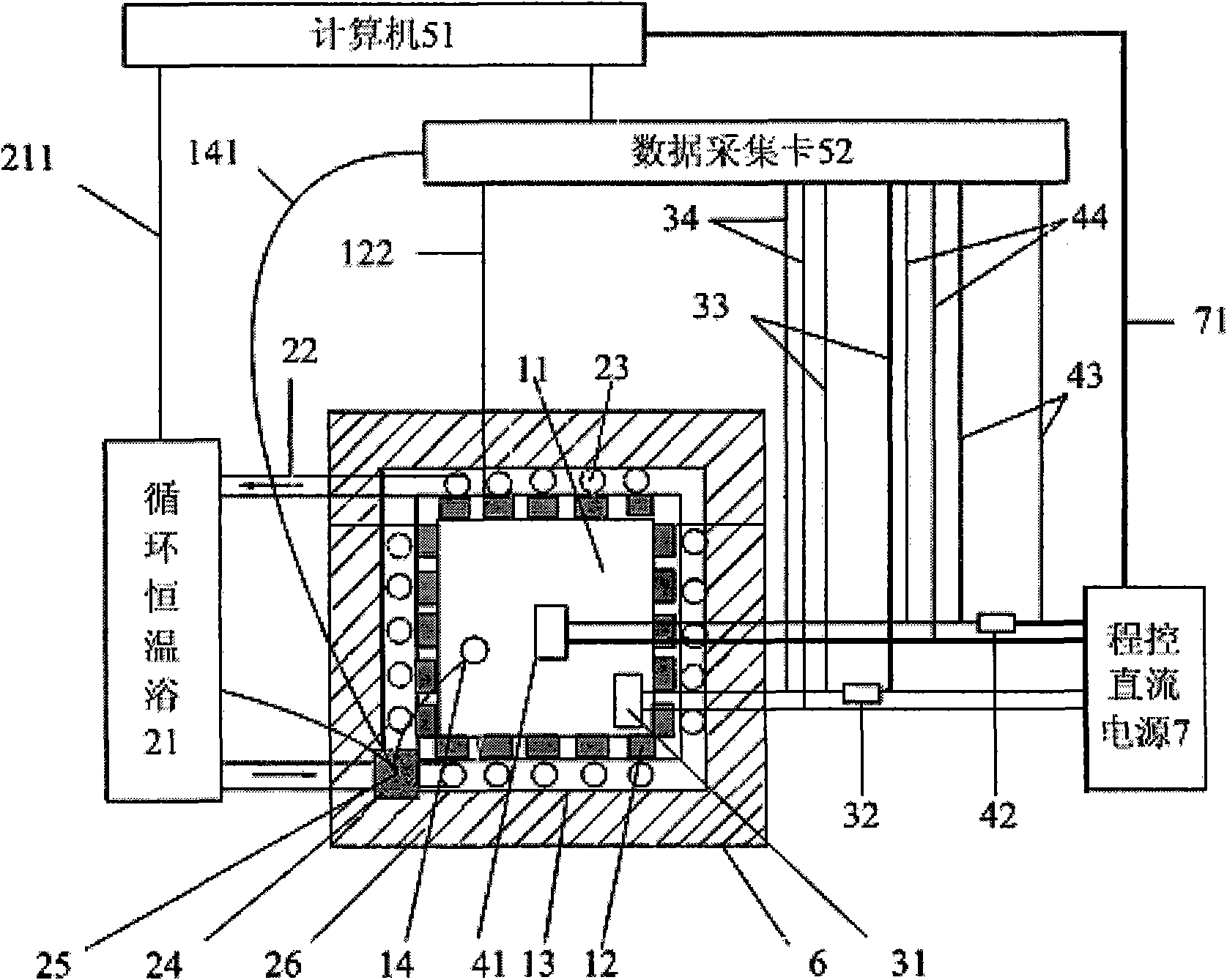

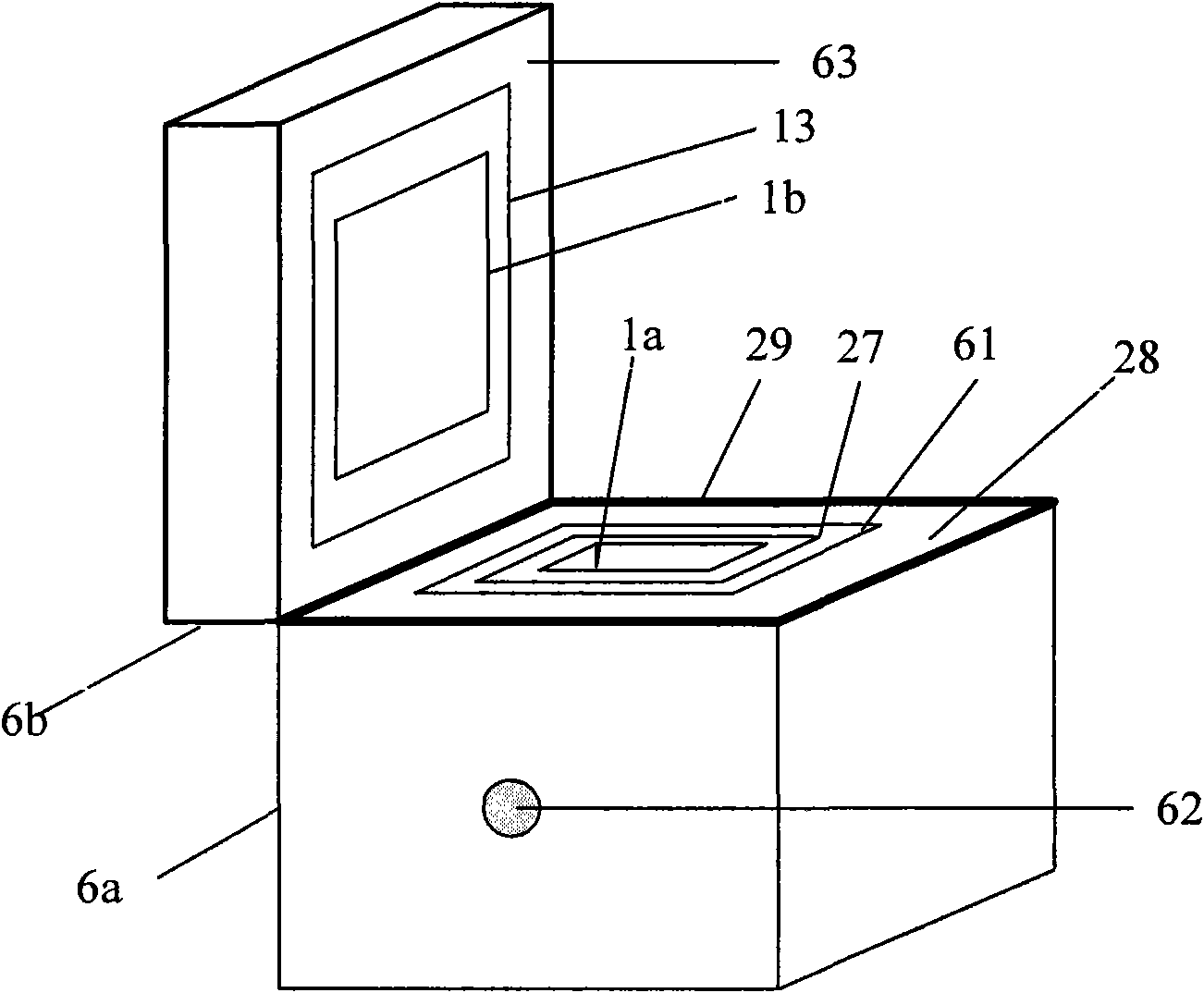

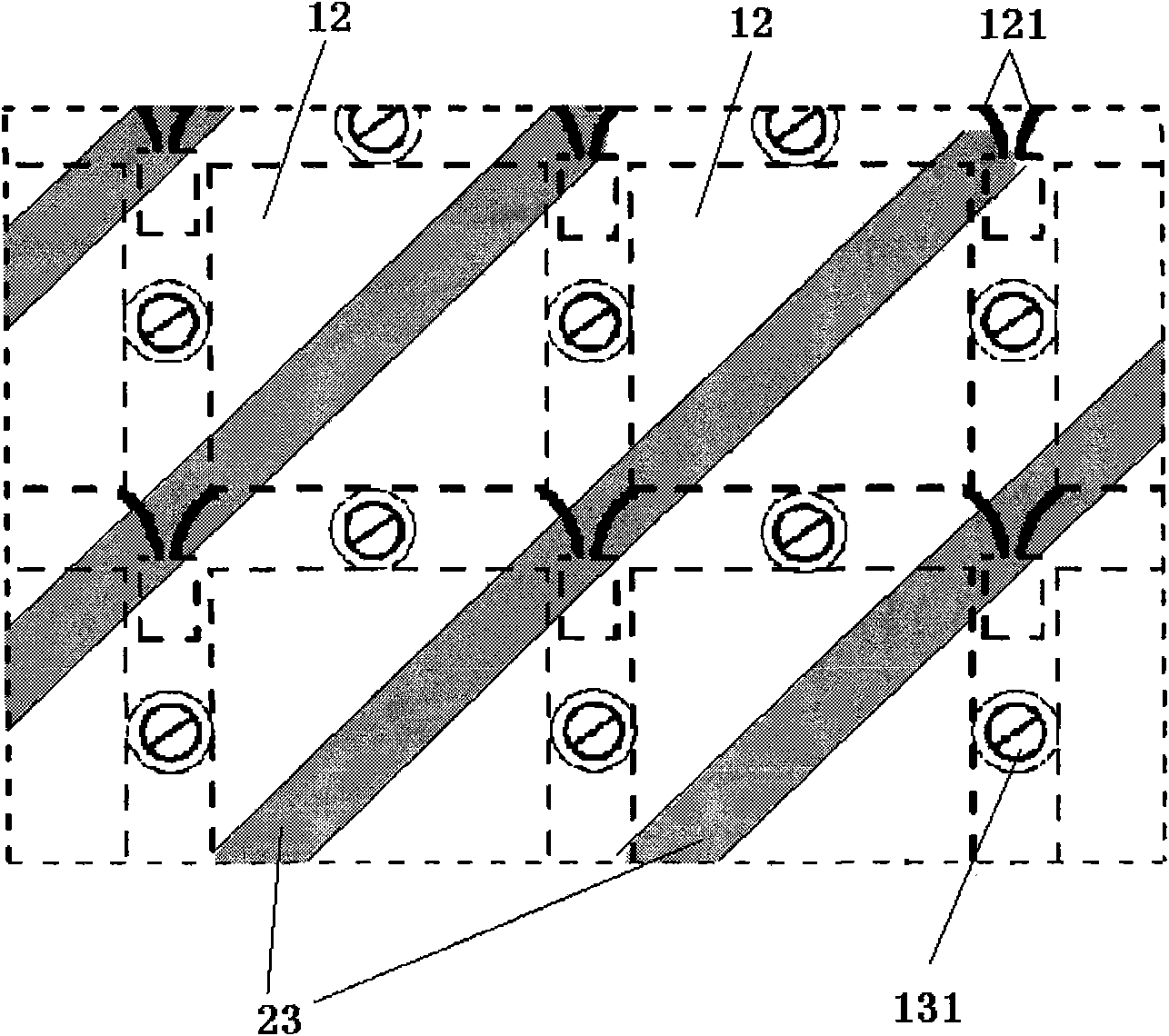

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a calorimeter 1 , a constant temperature insulation system 2 , a temperature uniform system 3 , a calibration system 4 , a signal processing and control system 5 and a box body 6 . Among them, the calorimeter 1 is a three-layer nested compound chamber structure as a whole, which includes a lower cylinder body 1a and an upper top cover 1b; the box 6 is wrapped outside the calorimeter 1, including the box body 6a and the box body The cover 6b corresponds to the upper and lower structure of the calorimeter 1 . The signal processing and control system 5 includes a computer 51 and a data acquisition card 52 . The calorimeter 1 is divided into a sample chamber 11 , a semiconductor thermoelectric module 12 and an outer wall 13 from the inside to the outside. The sample chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com