Method for detecting nickel-hydrogen battery separator wet electric resistance and device thereof

A nickel-metal hydride battery, resistance detection technology, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of difficult operation, low detection efficiency, poor sample clamping stability, etc., to improve the detection rate and accuracy. Improve the effect of simple and convenient detection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

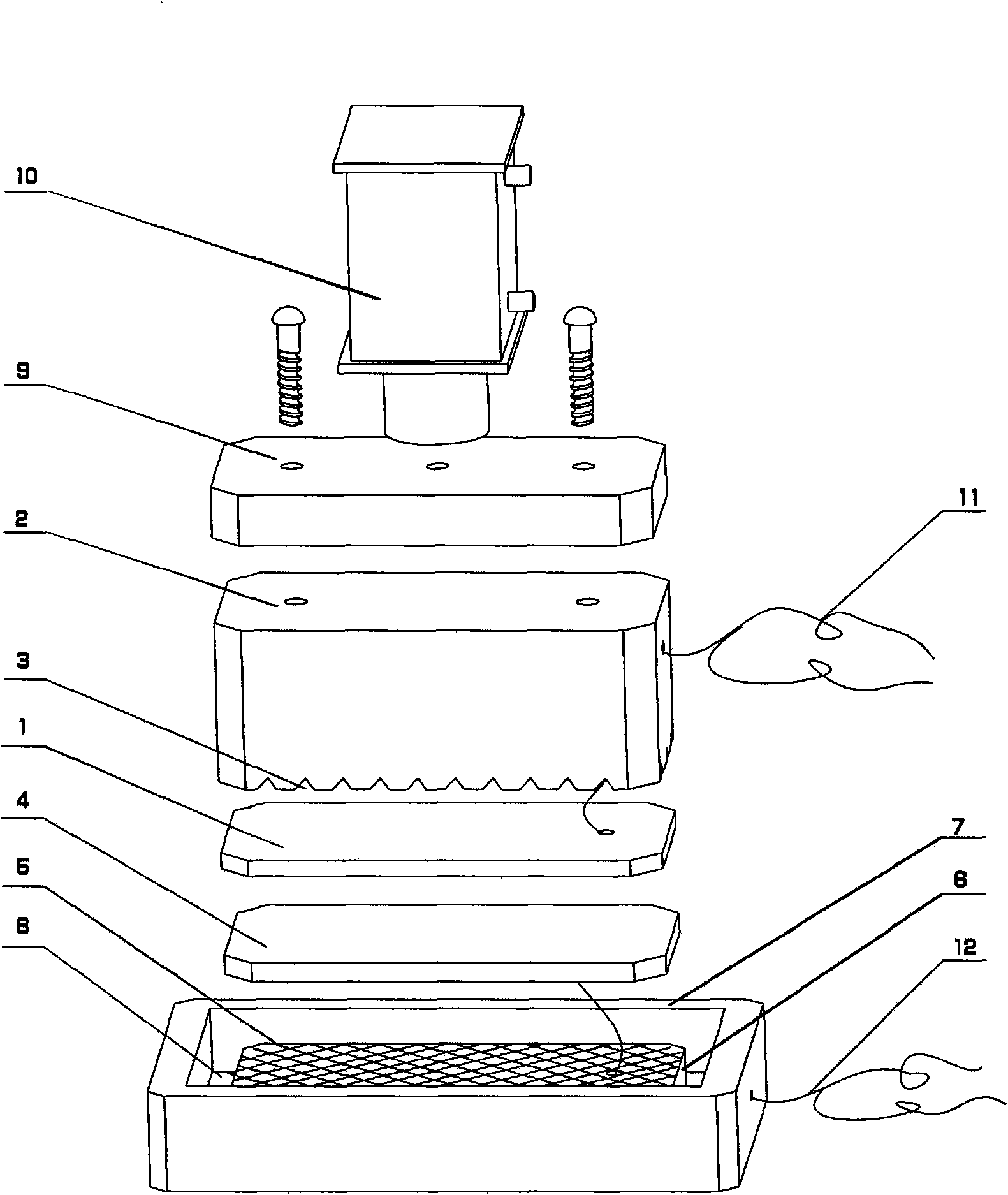

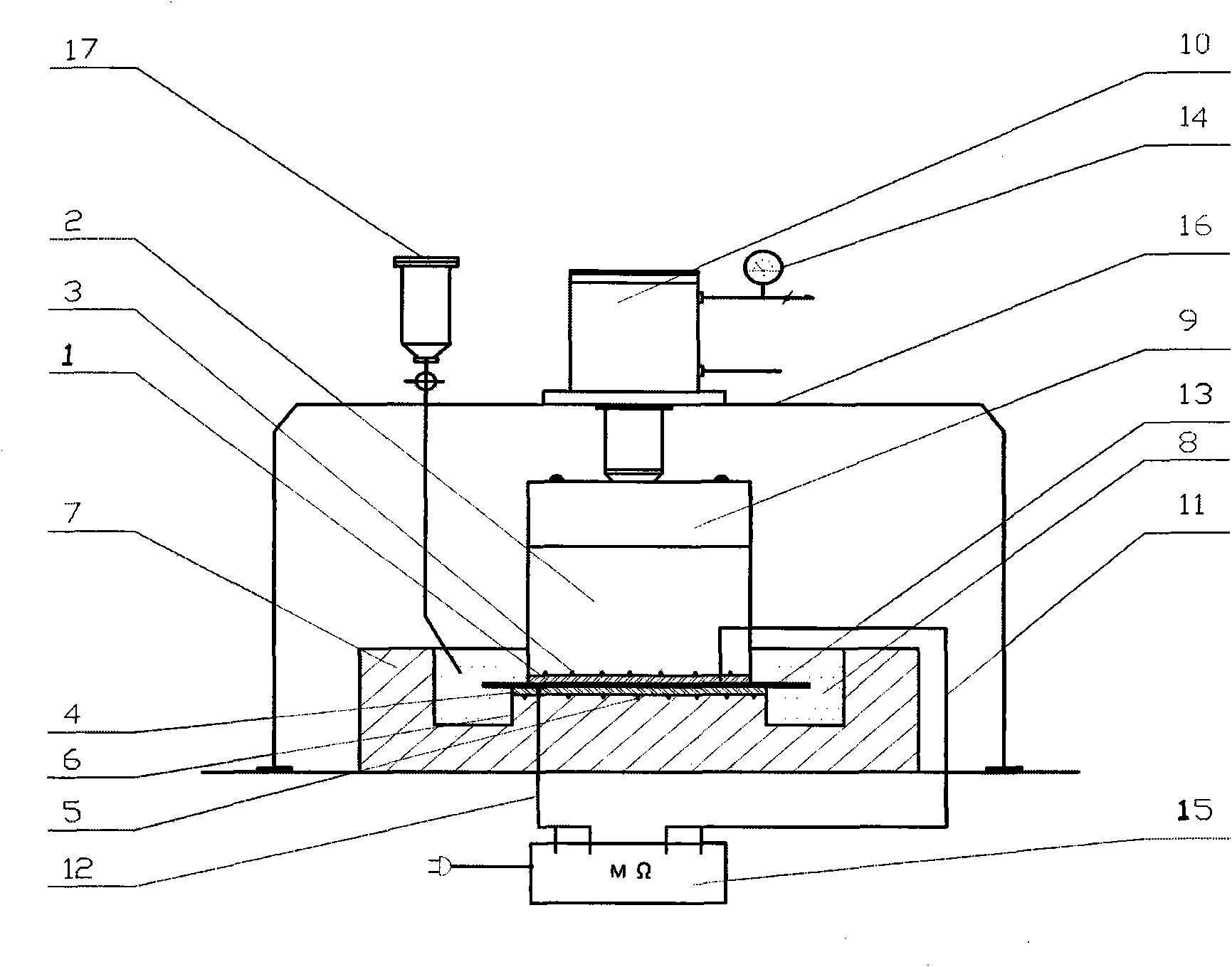

[0031] The invention provides a method and device for detecting wet resistance of a nickel-hydrogen battery diaphragm, and specific embodiments are as follows:

[0032] 1. The size of the porous electrode of this detection device is designed with reference to the size of the positive and negative plates of a nickel-hydrogen battery:

[0033] Upper electrode plate: width: 42 mm, length: 95 mm;

[0034] Lower electrode plate: width: 52 mm, length: 105 mm;

[0035] The nickel-metal hydride battery special foamed nickel metal sheet with a compacted thickness of 0.6 mm is cut and processed, and nickel wire leads are spot-welded to form a three-dimensional mesh porous electrode plate.

[0036] 2. The upper electrode support is made of hard fluoroplastics. The size of the support is 42 mm in width, 95 mm in length and 30 mm in thickness; the lower end is processed with a 1.5x1.5 mm V-shaped shallow groove, which is distributed at 45 degrees to form a diversion. groove. A porous upper ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com