Room temperature catalytic oxidation carbon monoxide catalyst and preparation method thereof

A technology for catalytic oxidation and carbon monoxide, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as short life, narrow applicable concentration range of CO catalytic purification, complex structure, etc., and achieve renewable The effect of regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Measure 0.0333mL of PdCl with a concentration of 0.423mol / L 2 Dilute HCl aqueous solution and dilute it to 0.5mL with deionized water to prepare impregnation solution;

[0020] 2) Add 0.5 g of 20-30 mesh γ-Al 2 o 3 Immerse the carrier in the above prepared impregnating solution, mix the carrier and the impregnating solution evenly, and immerse at 45°C for 2 hours to make a mixed impregnating solution;

[0021] 3) Dry the mixed impregnation solution at 120°C for 2 hours to prepare a catalyst for the catalytic oxidation of carbon monoxide at room temperature, in which PdCl 2 The content is 0.5% (wt).

[0022] The catalytic performance of the prepared catalyst was evaluated according to the aforementioned test conditions, and the conversion rate of the catalyst to a small amount of carbon monoxide was 98.4%.

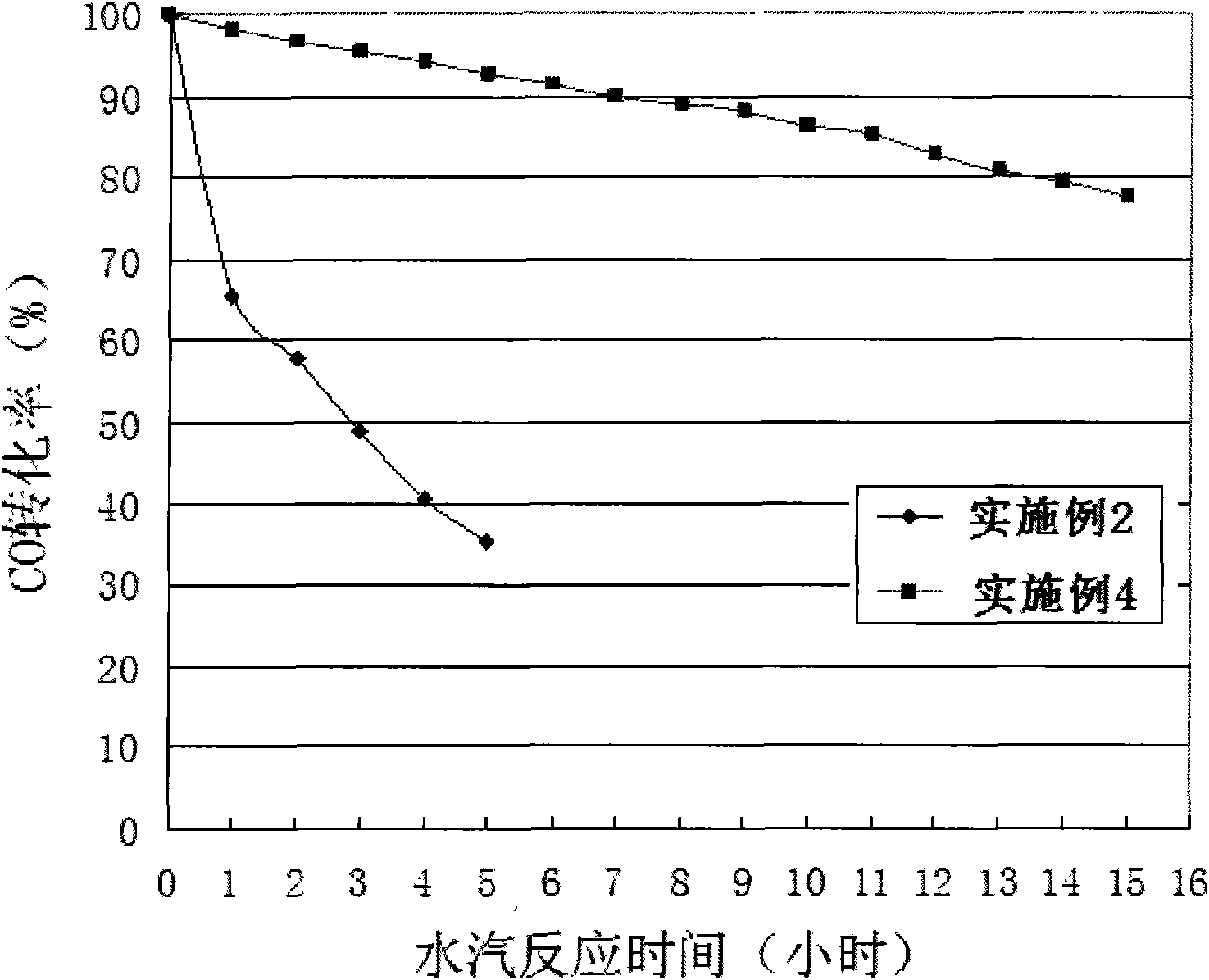

Embodiment 2

[0024] 1) Measure 0.0667mL of PdCl with a concentration of 0.423mol / L 2 Dilute HCl aqueous solution and dilute it to 0.5mL with deionized water to prepare impregnation solution;

[0025] 2) Add 0.5 g of 20-30 mesh γ-Al 2 o 3 Immerse the carrier in the above prepared impregnating solution, mix the carrier and the impregnating solution evenly, and immerse at 10°C for 2 hours to make a mixed impregnating solution;

[0026] 3) Dry the mixed impregnation solution at 120°C for 2 hours to prepare a catalyst for the catalytic oxidation of carbon monoxide at room temperature, in which PdCl 2 The content is 1.0% (wt).

[0027] The catalytic performance of the prepared catalyst was evaluated according to the aforementioned test conditions, and the conversion rate of the catalyst to a small amount of carbon monoxide was 99.7%.

Embodiment 3

[0029] 1) Measure 0.0333mL of PdCl with a concentration of 0.423mol / L 2 Dilute HCl aqueous solution and dilute it to 0.5mL with absolute ethanol to prepare impregnation solution;

[0030] 2) Add 0.5 g of 20-30 mesh γ-Al 2 o 3 Immerse the carrier in the prepared impregnating solution, mix the carrier and the impregnating solution evenly, and immerse at 80°C for 2 hours to make a mixed impregnating solution;

[0031] 3) Dry the mixed impregnation solution at 120°C for 2 hours to prepare a catalyst for the catalytic oxidation of carbon monoxide at room temperature, in which PdCl 2 The content is 0.5% (wt).

[0032] The catalytic performance of the prepared catalyst was evaluated according to the aforementioned test conditions, and the conversion rate of the catalyst to a small amount of carbon monoxide was 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com