Novel method for vulcanizing rubber-insulated electric wires and cables

A technology of insulated wires, wires and cables, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as the promotion and application of advanced technology and equipment bound by high-temperature rapid vulcanization systems, to reduce service life, easy to implement, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

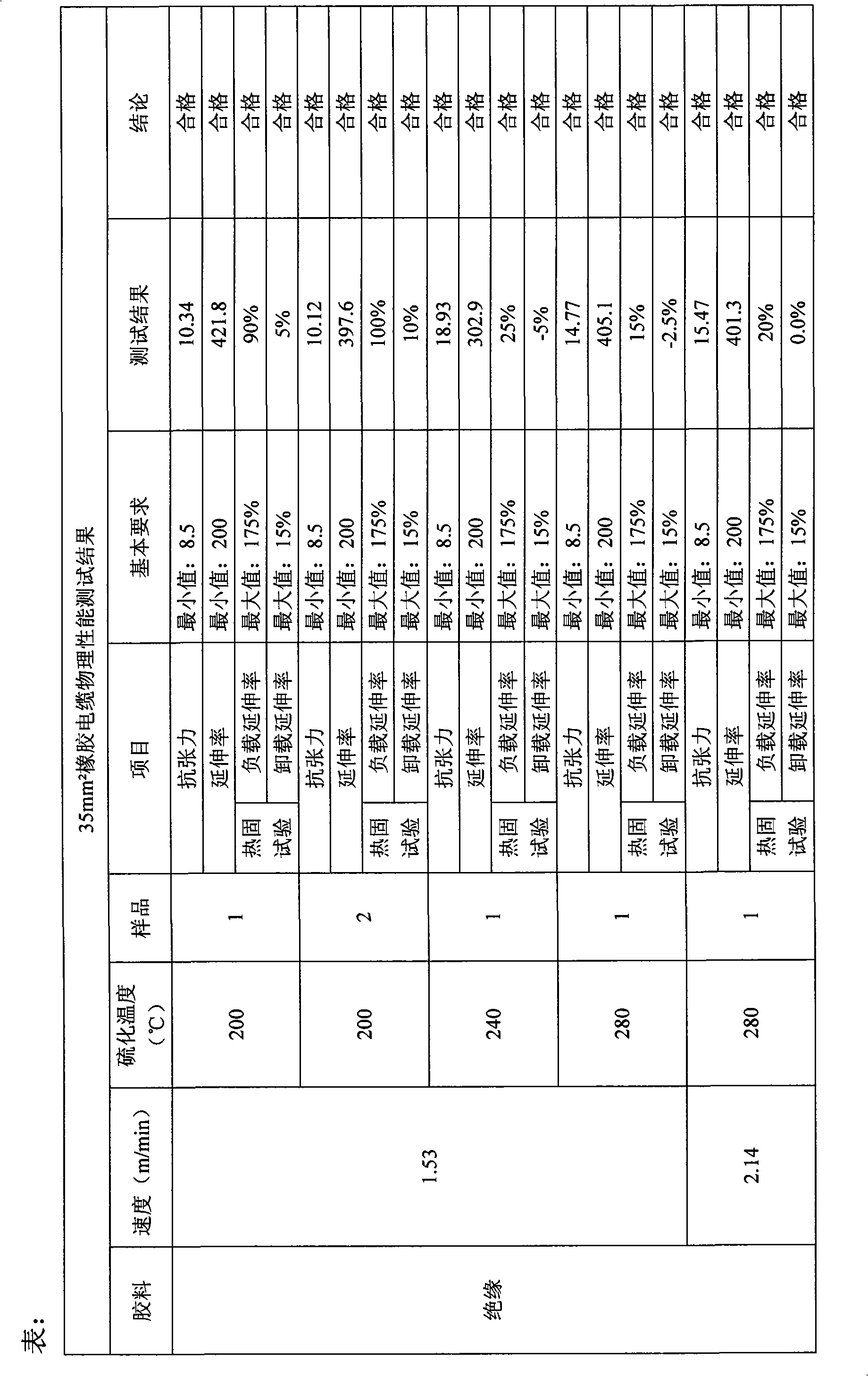

Image

Examples

Embodiment 1

[0015] Introduce nitrogen gas with a pressure of 0.5MPa into the vulcanization pipeline or container, and conduct electric radiation heating on the wire and cable through the vulcanization pipeline or container, and the electric radiation temperature is 240°C to complete the vulcanization process of rubber insulated wire and cable;

[0016] In this embodiment, the electrothermal radiation heating realizes short-circuit heating of the pipeline through a dry-type transformer, and then heats the vulcanization medium nitrogen.

Embodiment 2

[0018] Introduce nitrogen gas with a pressure of 0.6MPa into the vulcanization pipeline or container, conduct electric radiation heating on the wire and cable through the vulcanization pipeline or container, and the electric radiation temperature is 300°C, and complete the vulcanization process of rubber insulated wire and cable;

[0019] In this embodiment, the electrothermal radiation heating is to realize short-circuit heating of the pipeline through a dry-type transformer, and then heat the vulcanization medium nitrogen.

Embodiment 3

[0021] Introduce nitrogen gas with a pressure of 0.7MPa into the vulcanization pipeline or container, and conduct electric radiation heating on the wire and cable through the vulcanization pipeline or container, and the electric radiation temperature is 400°C to complete the vulcanization process of rubber insulated wire and cable;

[0022] In this embodiment, the electrothermal radiation heating realizes short-circuit heating of the pipeline through a dry-type transformer, and then heats the vulcanization medium nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com