Method for refining zinc by using slag containing zinc

A technology for zinc slag and filtering slag, which is applied in the field of recovering zinc in zinc-containing slag materials, can solve problems such as waste, pollution of land resources and water resources, harmful natural environment, etc., and achieves easy implementation, simple steps, and reduced waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

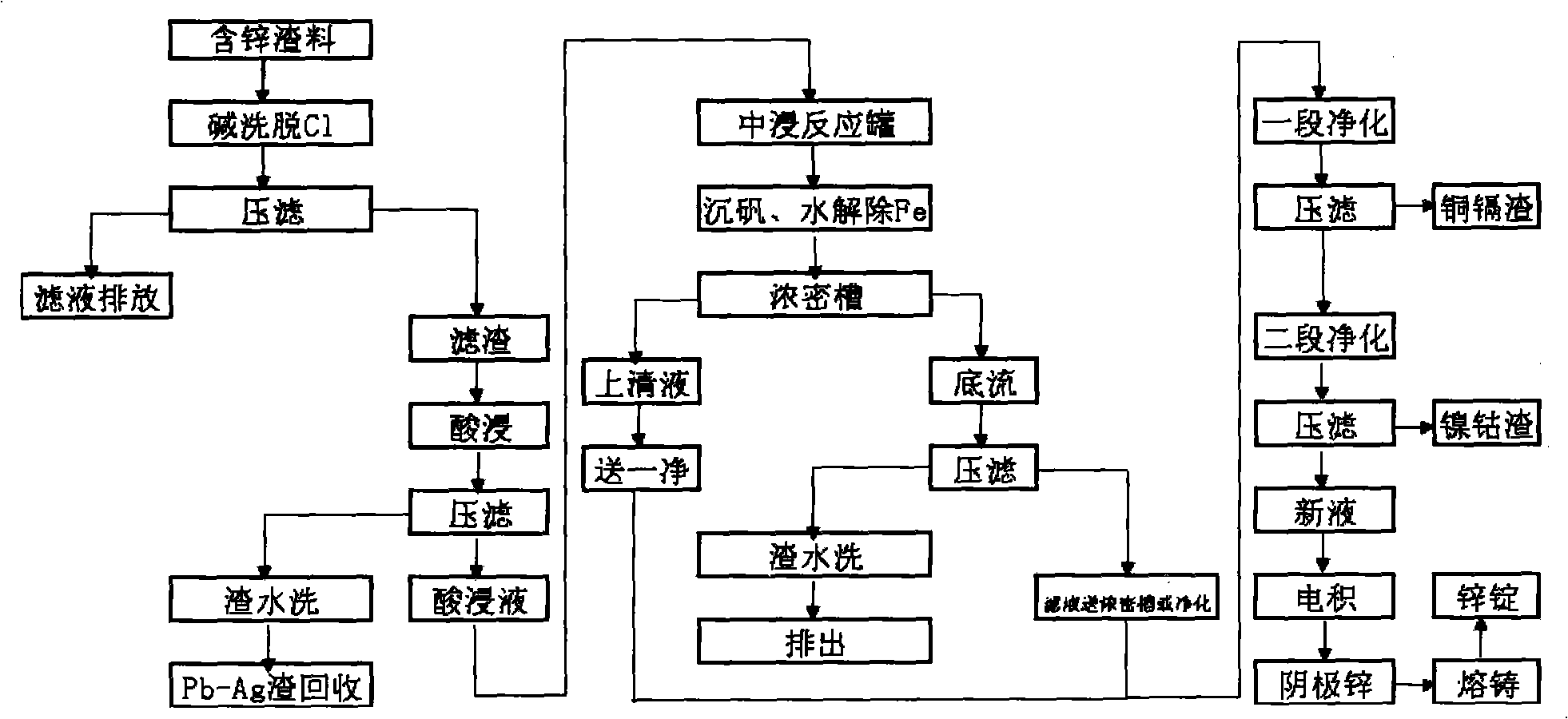

Image

Examples

Embodiment 1

[0021] Concrete process is (purification electrowinning step is the same as prior art, omits):

[0022] 1. Alkaline washing to remove chlorine

[0023] 1. Raw materials: zinc-containing slag, soda ash (Na 2 co 3 ),water

[0024] 2. Process purpose: The chlorine content in the zinc-containing slag material exceeds the standard, and directly putting it into production will cause a large amount of chlorine in the liquid to be enriched, which will seriously affect the electrolysis production. The purpose of alkali washing is to remove the chlorine adsorbed in the zinc-containing slag to meet the process requirements of electrolytic production.

[0025] 3. Process conditions: A. Control the liquid-solid ratio to 6-7:1, that is, every 6M 3 ~7M 3 Add 1 ton of zinc-containing slag to the water; B, temperature 70°C to 75°C; C, stirring reaction time: 1 hour to 2 hours; D, Na 2 co 3 The added amount is 4wt% of the amount of ZnO in the zinc-containing slag material.

[0026] 4. O...

Embodiment 2

[0040] Concrete process is (purification electrowinning step is the same as prior art, omits):

[0041] 1. Alkaline washing to remove chlorine

[0042] 1. Raw materials: zinc-containing slag, soda ash (Na 2 co 3 ),water.

[0043] 2. Process purpose: The chlorine content in the zinc-containing slag material exceeds the standard, and directly putting it into production will cause a large amount of chlorine in the liquid to be enriched, which will seriously affect the electrolysis production. The purpose of alkali washing is to remove the chlorine adsorbed in the zinc-containing slag to meet the process requirements of electrolytic production.

[0044] 3. Process conditions: A. Control the liquid-solid ratio to 7-8:1, that is, every 7M 3 ~8M 3 Add 1 ton of zinc-containing slag to the water; B, temperature 75°C to 80°C; C, stirring reaction time: 2 hours to 3 hours; D, Na 2 co 3 The added amount is 4wt% of the amount of ZnO in the zinc-containing slag material.

[0045] 4. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com