High-strength gas flue

A high-strength, flue gas technology, used in vertical pipes, building components, buildings, etc., can solve the problems of difficulty in reaching national industry standards, difficult maintenance of flue gas ducts, easy damage to transportation and installation, etc., and achieve light weight. , low cost, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

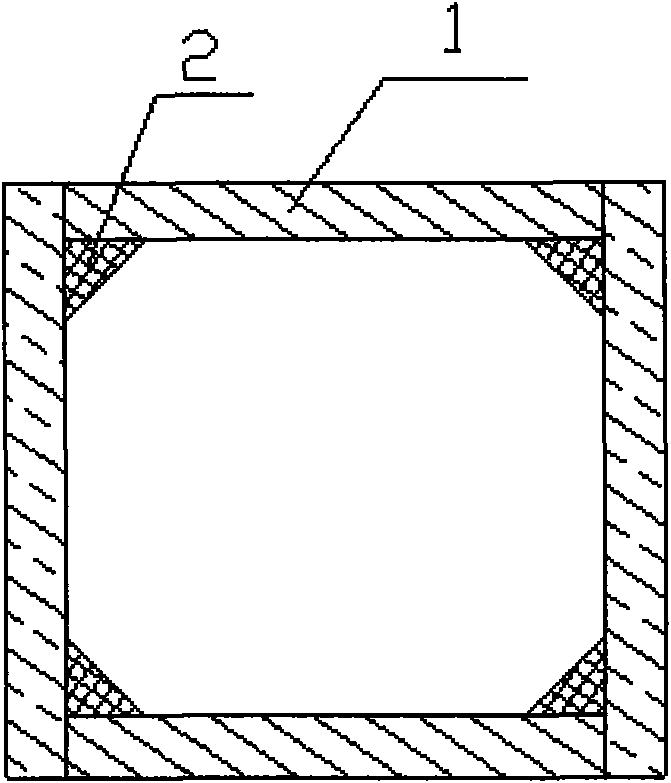

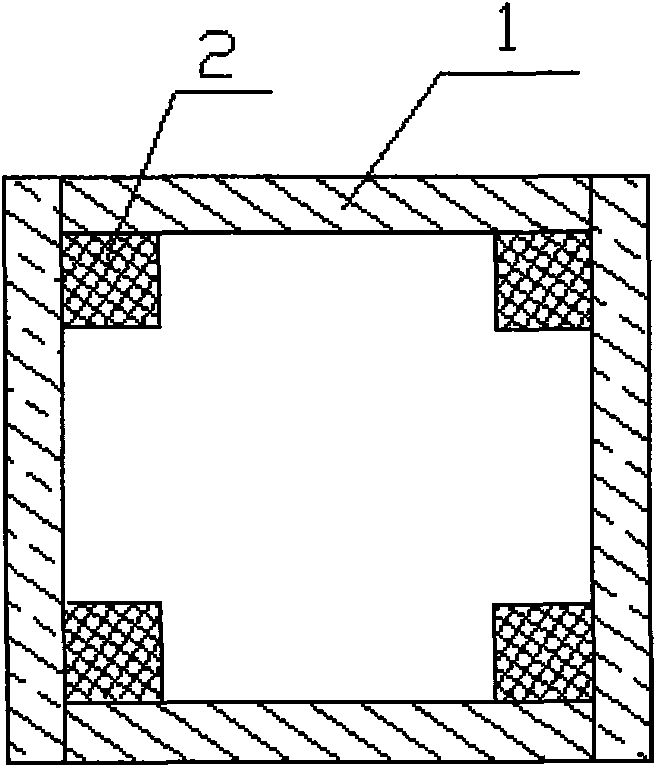

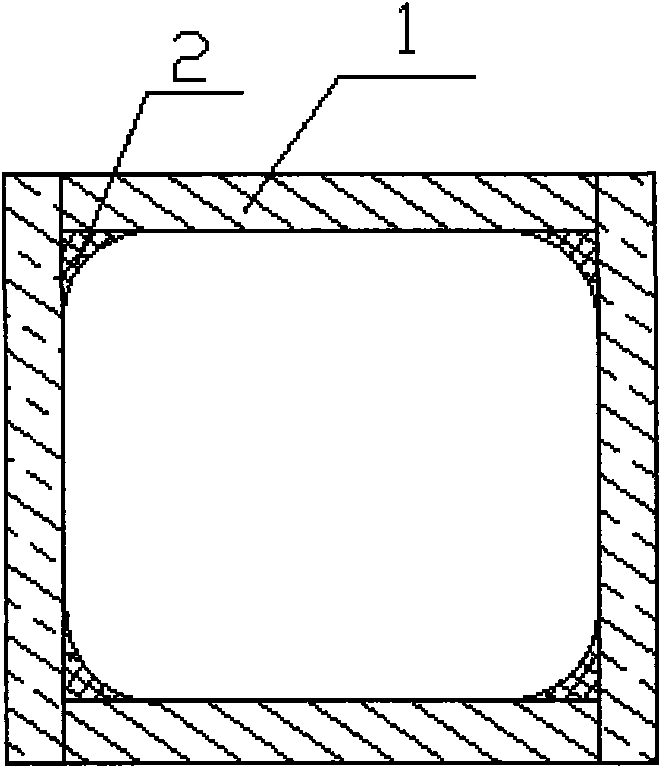

[0015] As shown in the figure, the flue gas channel is assembled by four side panels 1, its cross-section is rectangular, and its size depends on the needs. There are reinforcing ribs 2 at the four inner corners. The cross-sectional shape of the reinforcing ribs is There can be many shapes, such as triangle, rectangle, or arc. Adjacent side panels and between side panels and reinforcing ribs are bonded with high-strength, temperature-resistant, and corrosion-resistant glue, and at the same time, they are nailed together with woodworking nails. The side panel is composed of high-strength cement, magnesium ore, high-strength gypsum and glass fiber mesh as the main materials, and the fiber mesh is attached to the inner side of the side panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com