Hollow sucker rod

A hollow sucker rod and hollow technology, which is used in drill pipes, drilling equipment, earth-moving drilling, etc., can solve the problems of heavy pipe and rod, cable burnout, affecting oil well production, etc., to improve pump efficiency, increase oil production, The effect of reducing the number of well workover and well cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

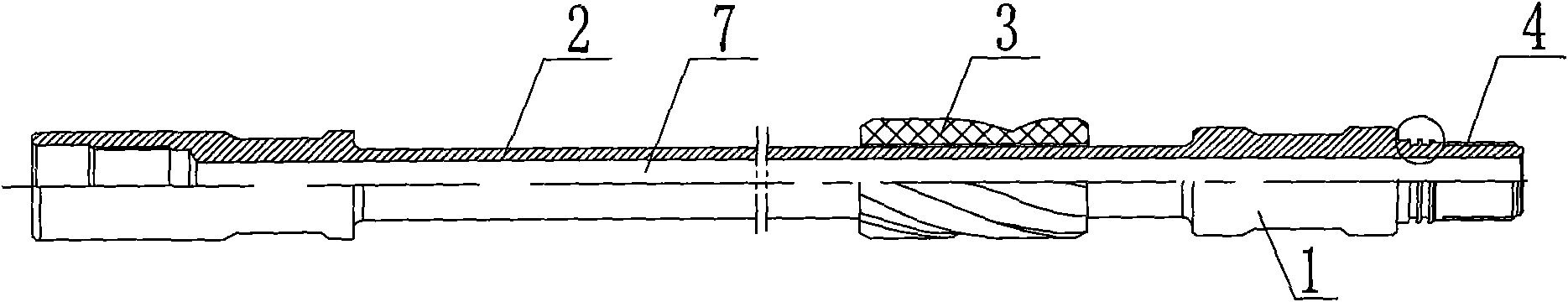

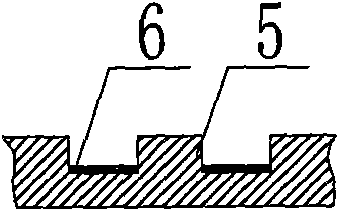

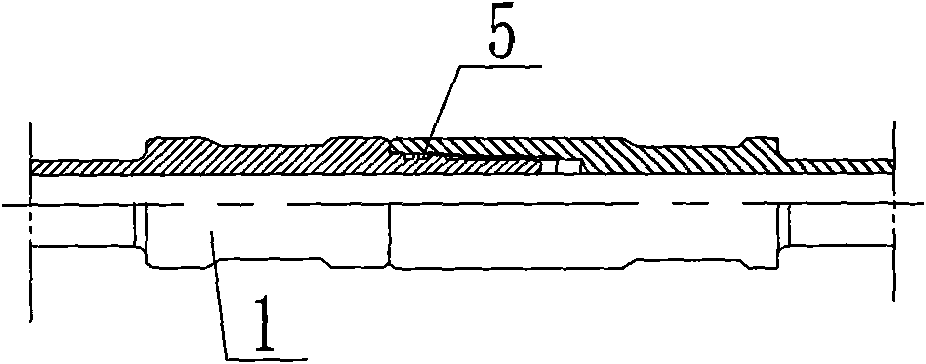

[0013] Referring to the accompanying drawings, such as figure 1 As shown, the hollow sucker rod includes a hollow joint 1 and a rod body 2. The rod body 2 has a hollow inner cavity 7. By adding various chemicals and hot oil to the inner cavity 7 of the rod body 2, the viscosity of crude oil can be reduced. Control wax deposition in oil wells and improve pump efficiency; the flow channel is small, the flow rate is fast, and it is not easy to deposit sand particles, which is suitable for sandy oil wells; it can replace oil pipes by matching with tubeless pumps; and the hollow sucker rod of the present invention has a large torsion resistance, Can drive screw pump.

[0014] The rod body 2 and one end of the hollow joint 1 are fixedly connected by friction welding. Through this connection method, the strength of the weld seam and the strength of the base material can be achieved, and the welding efficiency is high, the quality is stable, and the consistency is good. It can realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com