Multilayer tube for transporting water or gas

A multi-layer tube and barrier layer technology, applied in the field of multi-layer tubes, can solve problems such as functionalized fluoropolymers not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

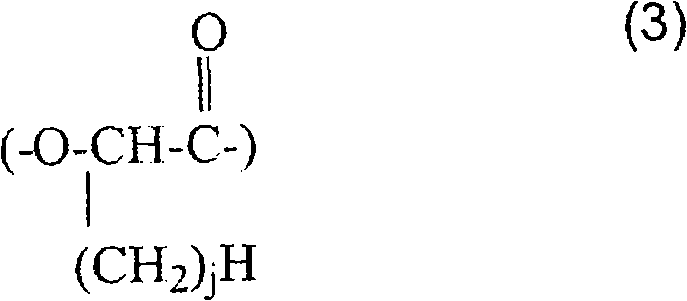

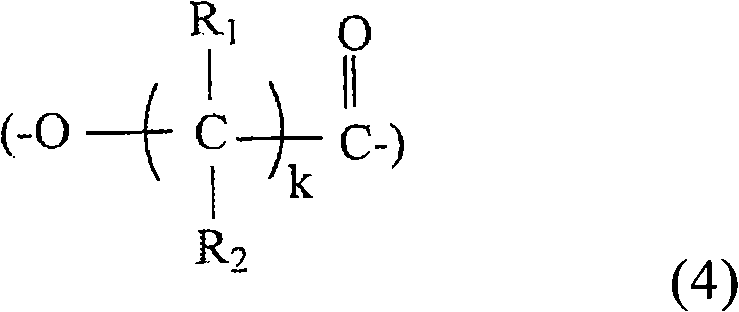

[0251] Embodiment 1: the preparation of functionalized PVDF

[0252] PVDF-1 was compounded with 2% by weight of maleic anhydride in a Weruer 40 type extruder at 190°C. The compounding is carried out under the following conditions: all outlets of the extruder are closed, the screw speed is 200 rpm and the throughput is 60 kg / h.

[0253] The product pelletized by the die face pelletizer was placed into bags with an impermeable aluminum liner. The bag was irradiated at 20 kGray. After irradiation, the product was passed through the extruder again at 245°C, maximum vacuum and 200 rpm. Throughput is 25kg / h. Infrared analysis of the product was carried out after this devolatilization step and showed: a degree of grafting of 0.31% and a content of free maleic anhydride of 300 ppm. This product is called functionalized PVDF 1 .

Embodiment 2

[0254] Embodiment 2: the preparation of functionalized PVDF

[0255] Repeat the conditions of Example 1, but with 720 replaces PVDF-1. Infrared analysis of the product after devolatilization showed a degree of grafting of 0.50% and a free maleic anhydride content of 300 ppm. This product is called functionalized PVDF 2 .

Embodiment 3

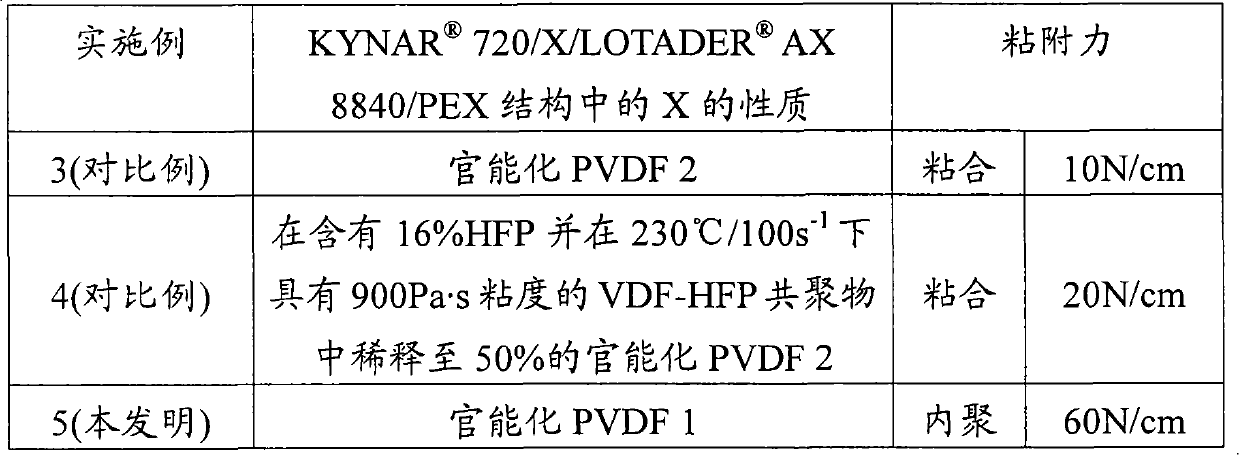

[0256] Embodiment 3 (comparative example)

[0257] A multilayer tube (outer diameter: 14mm) was produced using a McNeil extruder, the multilayer tube having the following structure:

[0258] 720(130μm) / functionalized PVDF 2(50μm) / AX8840(50μm) / PEX(780μm).

[0259] The PEX layer is the outer layer. All layers are adhered to each other. Extrude at 40m / min under the following conditions:

[0260] ·PE layer: 230℃

[0261] · AX8840: 250°C

[0262] ·Functionalized PVDF: 250℃

[0263] · 720: 250°C.

[0264] layer ensures excellent chemical protection of the PEX layer. After 5 days of extrusion, the functionalized PVDF and The adhesion between the 8840 layers was 10 N / cm. The adhesion is of the cohesive failure type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com