Advance drilling method for high-pressure water-rich filling cavity

An advanced drilling and water-rich technology, which is applied in the direction of filling, earthwork drilling, safety devices, etc., to achieve the effects of simple drilling steps, improved drilling efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

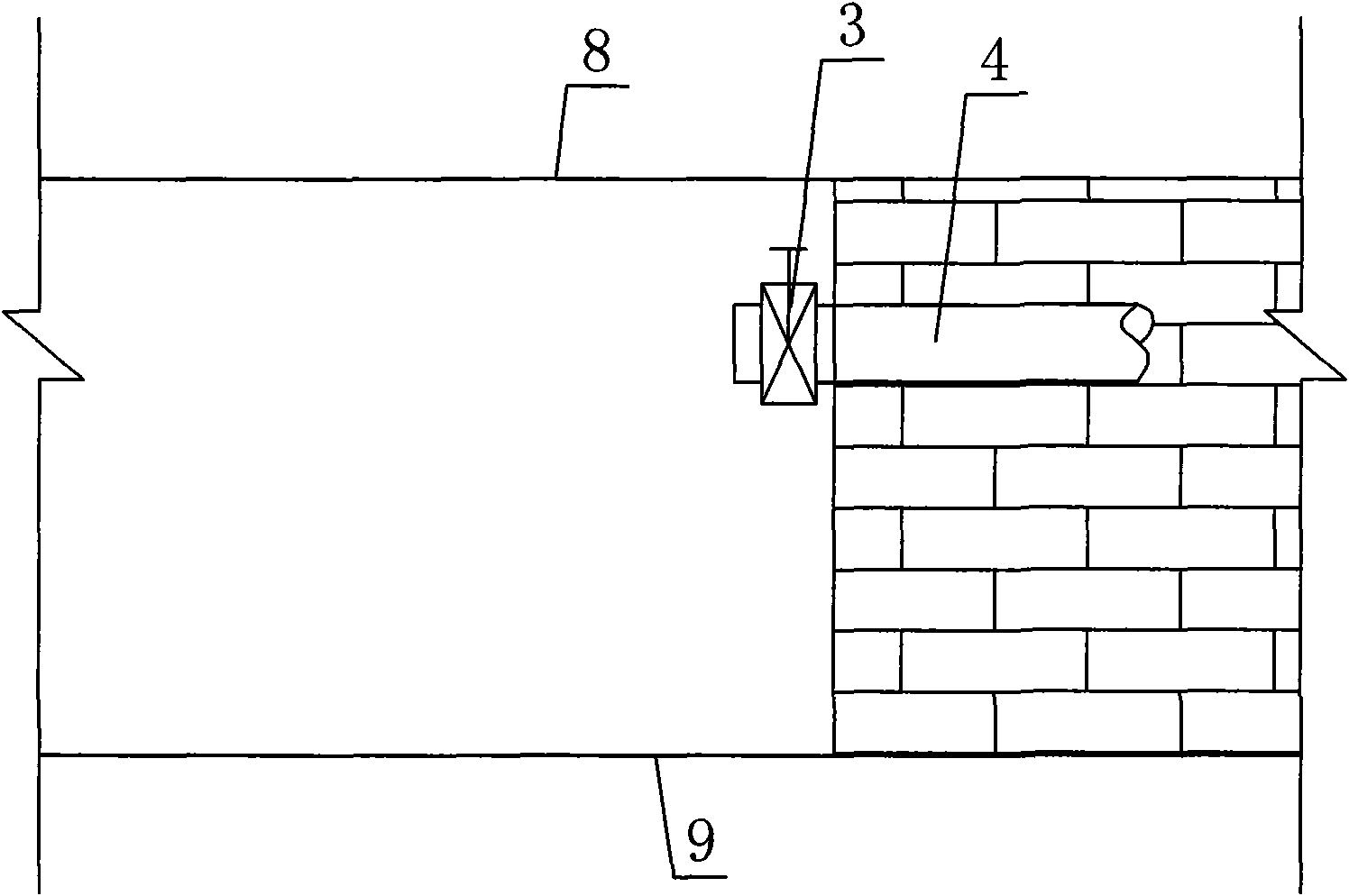

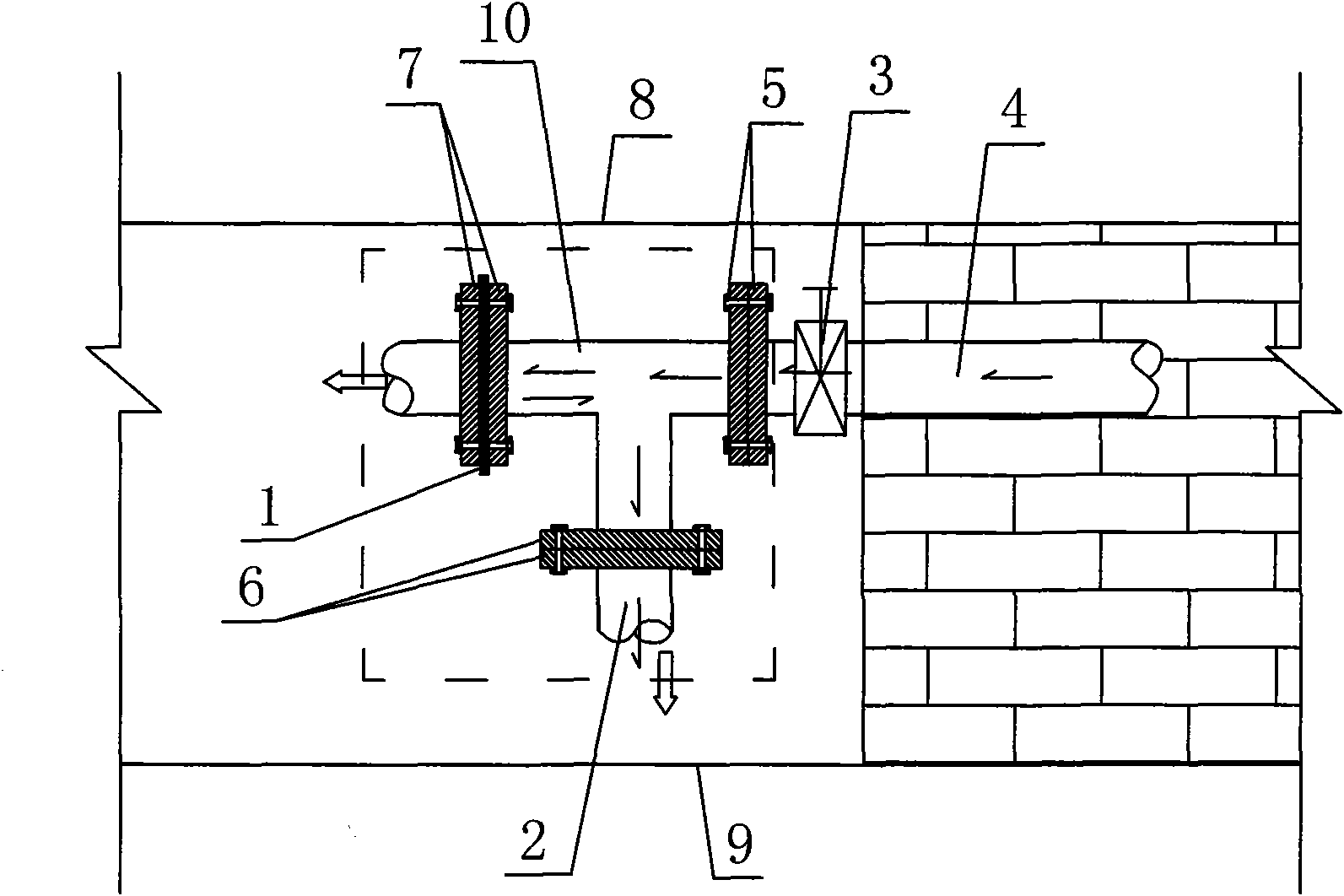

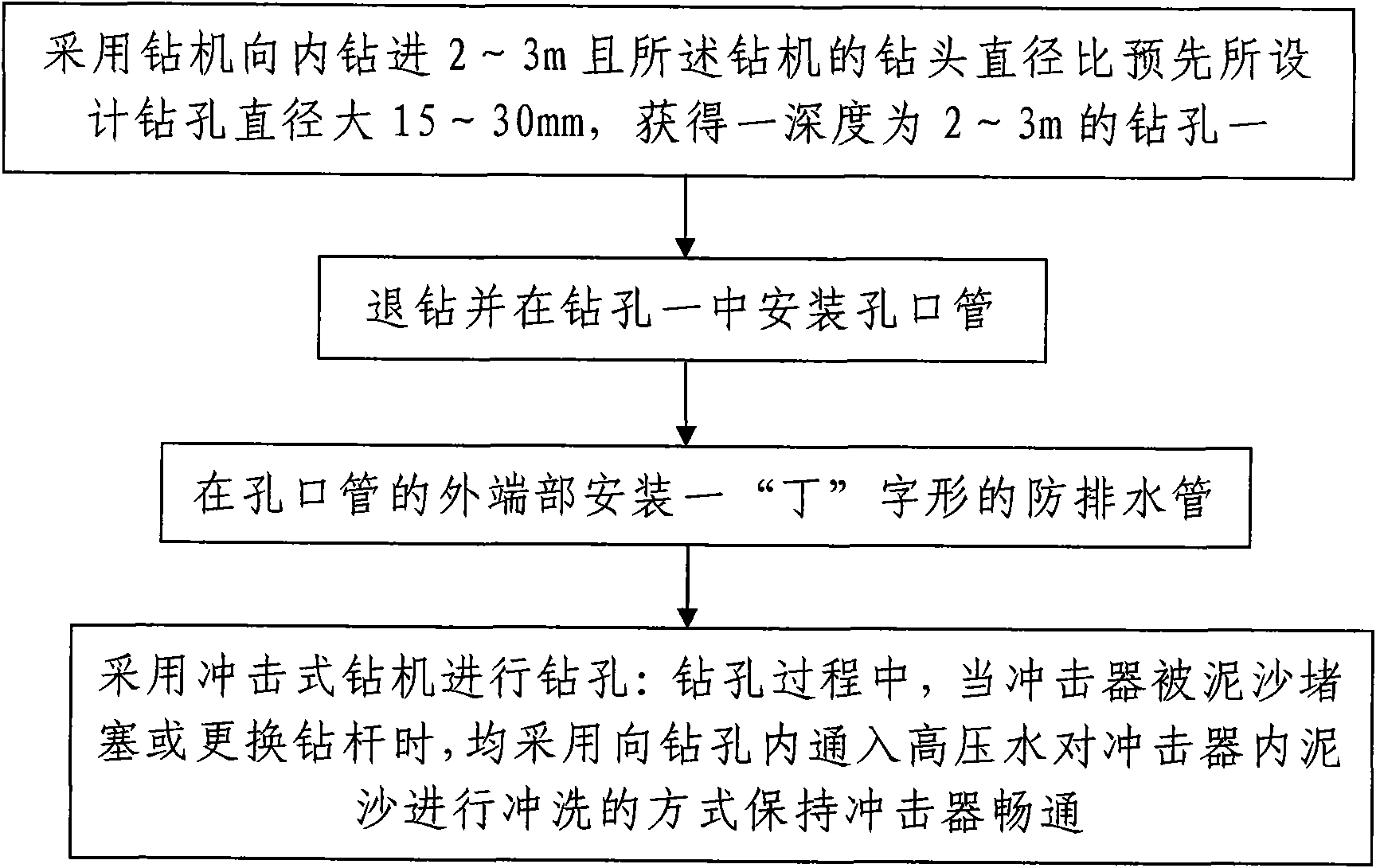

[0036] like figure 2 , image 3 As shown, the advanced drilling method for high-pressure rich water filling solution cavity described in the present invention comprises the following steps:

[0037] Step 1. According to the conventional advanced drilling technology of high-pressure water-rich filling solution cavity, use a drilling rig to drill 2-3m inward on the surface of the to-be-processed high-pressure water-rich filling solution cavity or water-rich stratum to be detected and the described The diameter of the drill bit of the drilling machine Φ is greater than the pre-designed drilling diameter Φ 0 15-30mm larger, to obtain a borehole 1 with a depth of 2-3m and a diameter of Φ; then withdraw the drilling machine from the borehole 1, and install a borehole 1 with an outer diameter of Φ and a length longer than the borehole 1 A length of orifice pipe 4 and the orifice pipe 4 is extended to the inner bottom of the first borehole, and a high-pressure water stop gate valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com