Blumea oil microcapsule antibacterial mask and preparation method thereof

A technology of microcapsules and mugwort oil, which is applied in botany equipment and methods, clothing, animal repellents, etc., can solve the problems of high investment in finishing equipment, poor finishing effect, poor washability, etc., and reach the level of formaldehyde emission Decrease or increase the durable washing effect and the effect of reducing the anti-wrinkle function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

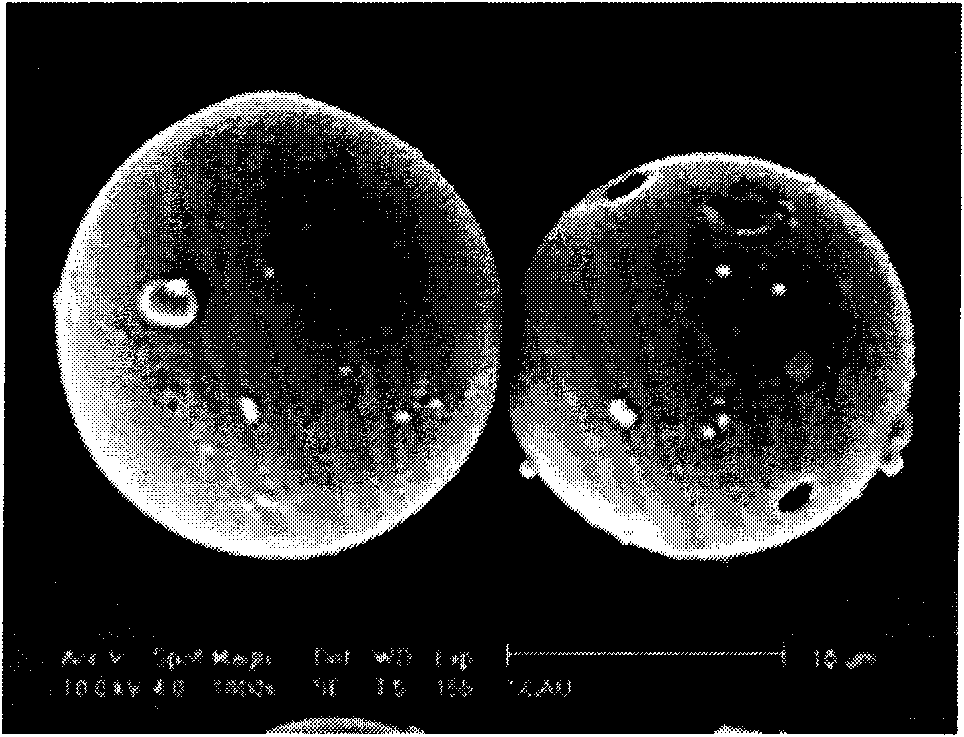

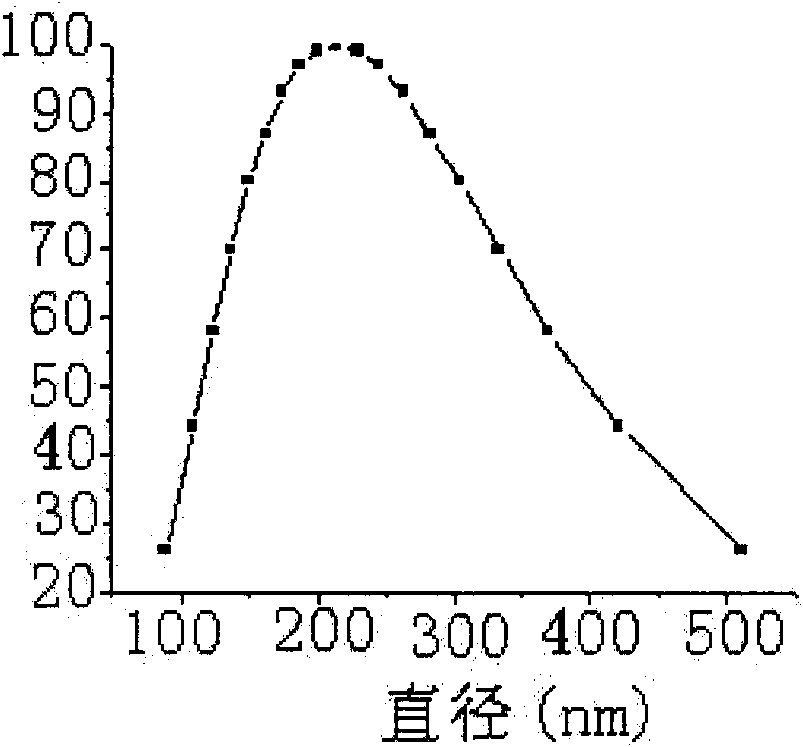

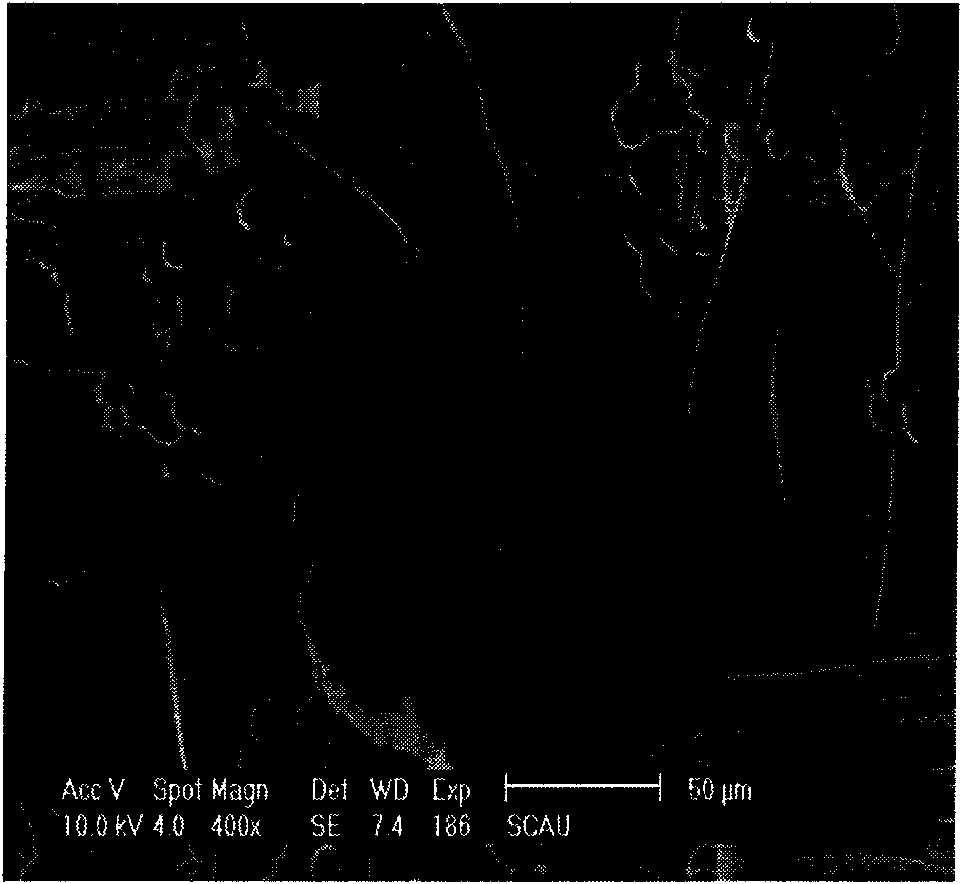

[0032] (1) Preparation of mugwort oil microcapsule emulsion: Weigh 0.50g of gelatin and 0.50g of gum arabic into a 250mL three-neck flask, add 50g of distilled water, stir and dissolve in a water bath at 40°C, add 0.50g of mugwort oil and stir Emulsify for 15min. Gradually add 20% acetic acid (HAC) dropwise to the above emulsion to adjust the pH value of the solution to 4.0, reduce the stirring speed to 400r / min, and re-coagulate for 15 minutes; cool the above-mentioned condensed suspension to 0°C with an ice-water bath , then adjust the pH value of the system to 8.0-9.0 with 20% NaOH solution, add dropwise an appropriate amount of 25% glutaraldehyde solution (3-8ml), and then add an appropriate amount of deionized water until the total amount of the emulsion is 100 grams. Continue to ice-bath for 30 minutes under the condition of / min; move to a water bath at 50° C. to continue cross-linking and solidification for 2 hours to obtain a microcapsule emulsion product with a wormw...

Embodiment 2

[0048] (1) Preparation of mugwort oil microcapsule emulsion: Weigh 5g of gelatin and 4.5g of gum arabic into a 250mL three-neck flask, add 60g of distilled water, stir and dissolve in a water bath at 40°C, add 6g of mugwort oil and emulsify for 15min under stirring . Gradually add 20% HAC dropwise to the above emulsion to adjust the pH value of the solution to 4.0, reduce the stirring speed to 600r / min, and re-coagulate for 15 minutes; cool the above-mentioned condensed suspension to 3°C with an ice-water bath, and then use 20% NaOH solution to adjust the pH value of the system to 8.0-9.0, add 5ml (about) 25% glutaraldehyde solution dropwise, and then add an appropriate amount of deionized water until the total amount of the emulsion is 100 grams. Under the condition of stirring speed 600r / min Continue to ice-bath for 30 minutes; move to a water bath at 50° C. to continue cross-linking and solidification for 2 hours to obtain a microcapsule emulsion product with a 6% mugwort o...

Embodiment 3

[0055] (1) Preparation of mugwort oil microcapsule emulsion: Weigh 2g of gelatin and 2g of gum arabic into a 250mL three-neck flask, add 50g of distilled water, stir and dissolve in a water bath at 40°C, add 3g of mugwort oil and emulsify for 15min under stirring. Gradually add 20% HAC dropwise to the above emulsion to adjust the pH value of the solution to 4.0, reduce the stirring speed to 500r / min, and re-coagulate for 15 minutes; cool the above-mentioned coagulated suspension to 0-5°C with an ice-water bath, Then use 20% NaOH solution to adjust the pH value of the system to 8.5, add 3ml of 25% glutaraldehyde solution dropwise, then add an appropriate amount of deionized water until the total amount of the emulsion is 100 grams, and continue the ice bath under the condition of a stirring speed of 500r / min 30 min; move into a water bath at 50° C. to continue cross-linking and curing for 2 hours to obtain a microcapsule emulsion product with a content of 3% mugwort leaf oil.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com