Tasteless quick-releasing berberine hydrochloride pellet

A technology of berberine hydrochloride and pellets, which is applied in the direction of bulk delivery, medical preparations of non-active ingredients, cardiovascular system diseases, etc., can solve the problems of affecting bioavailability and poor absorption of berberine hydrochloride, and achieve delay release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

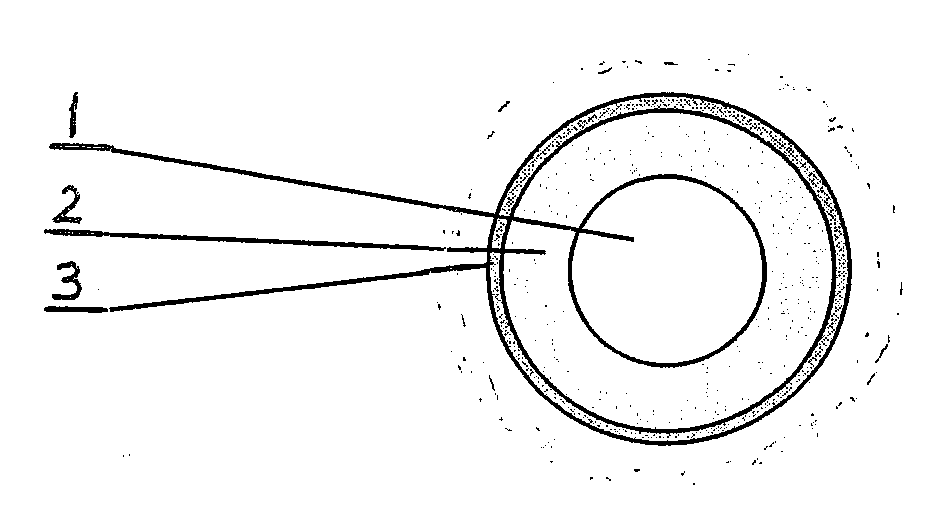

Image

Examples

Embodiment 1

[0029] Step 1: Production of base pill core:

[0030] Percentage by weight: microcrystalline cellulose: 50%, starch: 30%, low-substituted-hydroxypropyl cellulose: 20%, and a diameter of 0.2-0.7mm to make nearly round particles with 8% polyvinylpyrrolidone aqueous solution. Fluidized bed drying and sieving to make the moisture content of the finished product ≤5%.

[0031] Step 2: Production of taste-masking coating powder:

[0032] Percentage by weight: after mixing fine powders of acrylic resin IV: 30%, magnesium stearate: 45%, and talcum powder: 25%, add ethanol to prepare a 5% solution.

[0033] Step 3: Production of tasteless immediate-release berberine hydrochloride pellets:

[0034] According to percentage by weight: berberine hydrochloride: 30%, adjuvant; 50% (making fast disintegrating type base pill core), masking taste coating material: 20% requirement, the base pellet core core that will make is placed in fluid flow In the fluidized bed, spray into the prepared be...

Embodiment 2

[0036] Step 1: Production of base pill core:

[0037] Percentage by weight: microcrystalline cellulose: 45%, starch: 38%, low-substituted-hydroxypropyl cellulose: 17%, with 8% polyvinylpyrrolidone aqueous solution to make a diameter of 0.2-0.7mm near round particles, through Fluidized bed drying and sieving to make the moisture content of the finished product ≤5%.

[0038] Step 2: Production of taste-masking coating powder:

[0039] Percentage by weight: prepare the acrylic resin IV solution: 40% acrylic resin IV, 35% magnesium stearate, 25% talcum powder: add ethanol to prepare an 8% solution.

[0040] Step 3: Production of tasteless immediate-release berberine hydrochloride pellets:

[0041] According to percentage by weight: berberine hydrochloride: 35%, adjuvant; 40% (make fast disintegrating type base pill core), cover taste coating material: 25% requirement, the base pill that will make is added in fluidized bed Inside, first spray into the prepared berberine hydrochl...

Embodiment 3

[0043] Step 1: Production of base pill core:

[0044] Percentage by weight: microcrystalline cellulose: 45%, starch: 40%, low-substituted hydroxypropyl cellulose: 15%, made with 8% polyvinylpyrrolidone aqueous solution with a diameter of 0.2-0.7mm yellow nearly round particles , dried in a fluidized bed and sieved to make the moisture content of the finished product ≤5%.

[0045] Step 2: Production of taste-masking coating powder:

[0046] Percentage by weight: acrylic resin IV: 35%, magnesium stearate: 30%, and talcum powder: 35%, and ethanol is added to prepare a 6% solution.

[0047] Step 3: Production of tasteless immediate-release berberine hydrochloride pellets:

[0048] Percentage by weight: berberine hydrochloride: 32%, adjuvant; 40% (made of fast-disintegrating base pellet core), taste-masking coating material: 28%, the prepared base pellet core is placed in a fluidized bed Inside, first spray the prepared mixed solution of berberine hydrochloride and polyvinylpyrr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com