Strength fitness equipment and method for manufacturing same

A fitness equipment and strength technology, applied in gymnastics equipment, sports accessories, etc., can solve the problems of inability to process, easy contact with the human body, increase safety costs, etc., and achieve the effect of convenient installation and maintenance, simple process, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

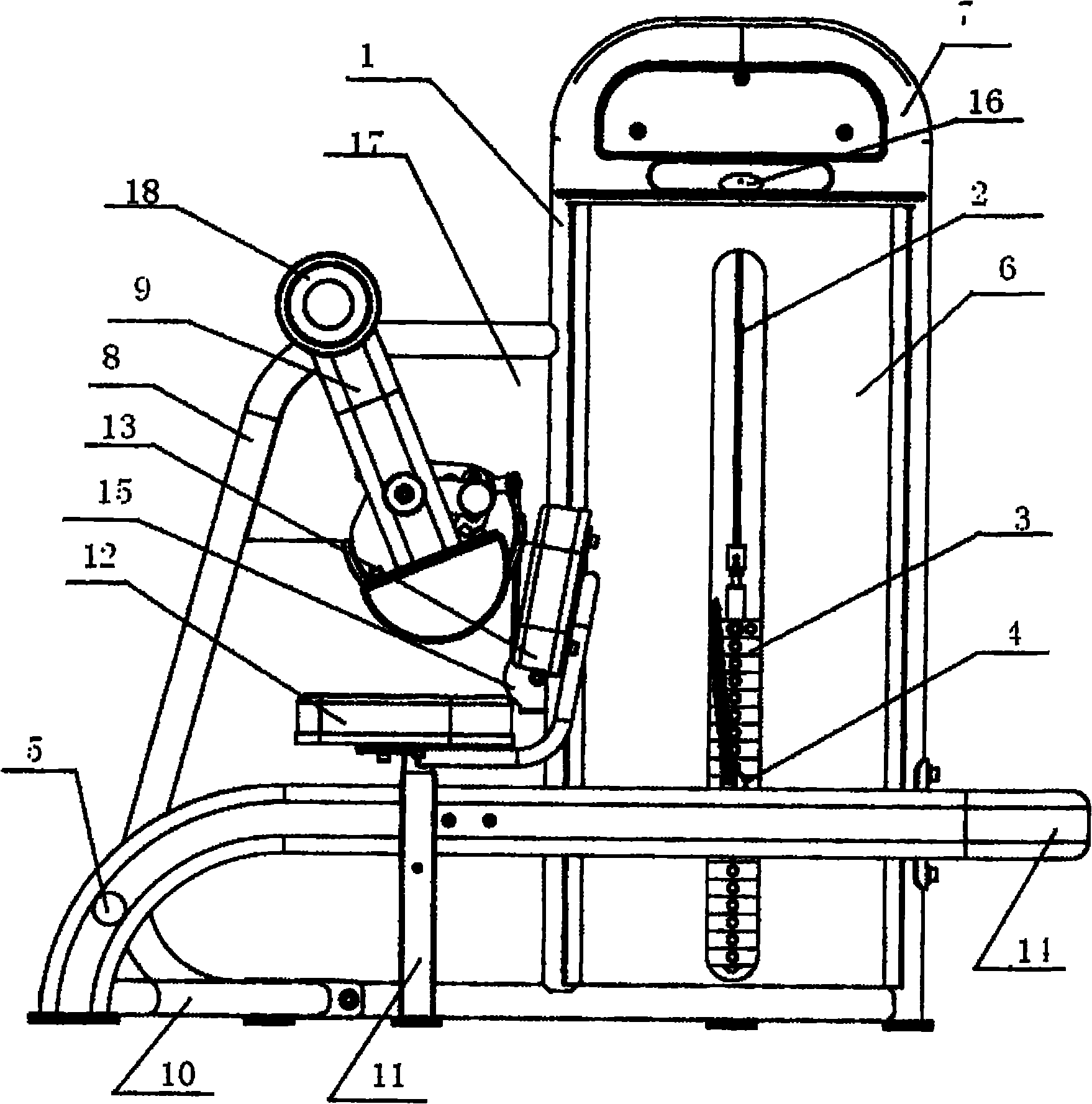

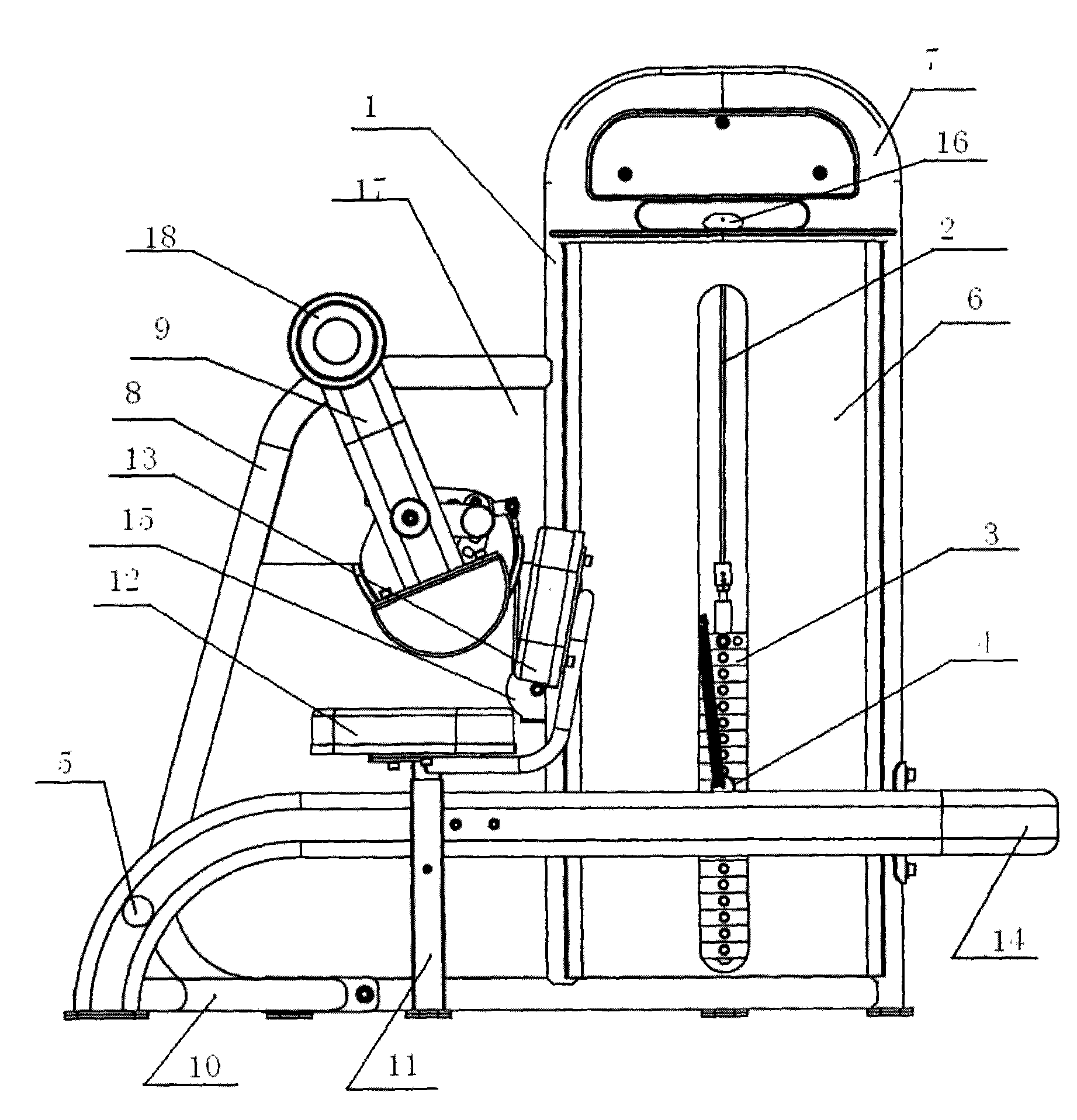

[0011] like figure 1 Shown: a strength fitness equipment, including U-shaped steel pipe 1, steel wire rope 2, selection piece 3, selection pin 4, pedal device 5, translucent baffle 6, protective cover 7, main frame 8, arm pad assembly frame 9 , bottom connection frame 10, cushion group frame 11, seat cushion 12, back cushion 13, rear support frame 14, U-shaped steel pipe 1 can be square pipe, round pipe, oval pipe, D-shaped pipe, and the thickness of U-shaped steel pipe 1 is 1.5 ~5MM, U-shaped steel pipe 1 has an inner single-sided groove at the rounded corner. The inner single-sided groove can be square, circular, triangular, trapezoidal or poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com