Method for continuously measuring carbon content of molten steel in electric steelmaking furnace

An electric furnace steelmaking and measurement method technology, applied in the field of metallurgical steelmaking, can solve the problems of large errors in molten steel carbon content, affecting the consumption of raw and auxiliary materials, and affecting the production of electric furnace steelmaking, so as to improve production efficiency, save samplers, The effect of prolonging the life of the refractory material in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

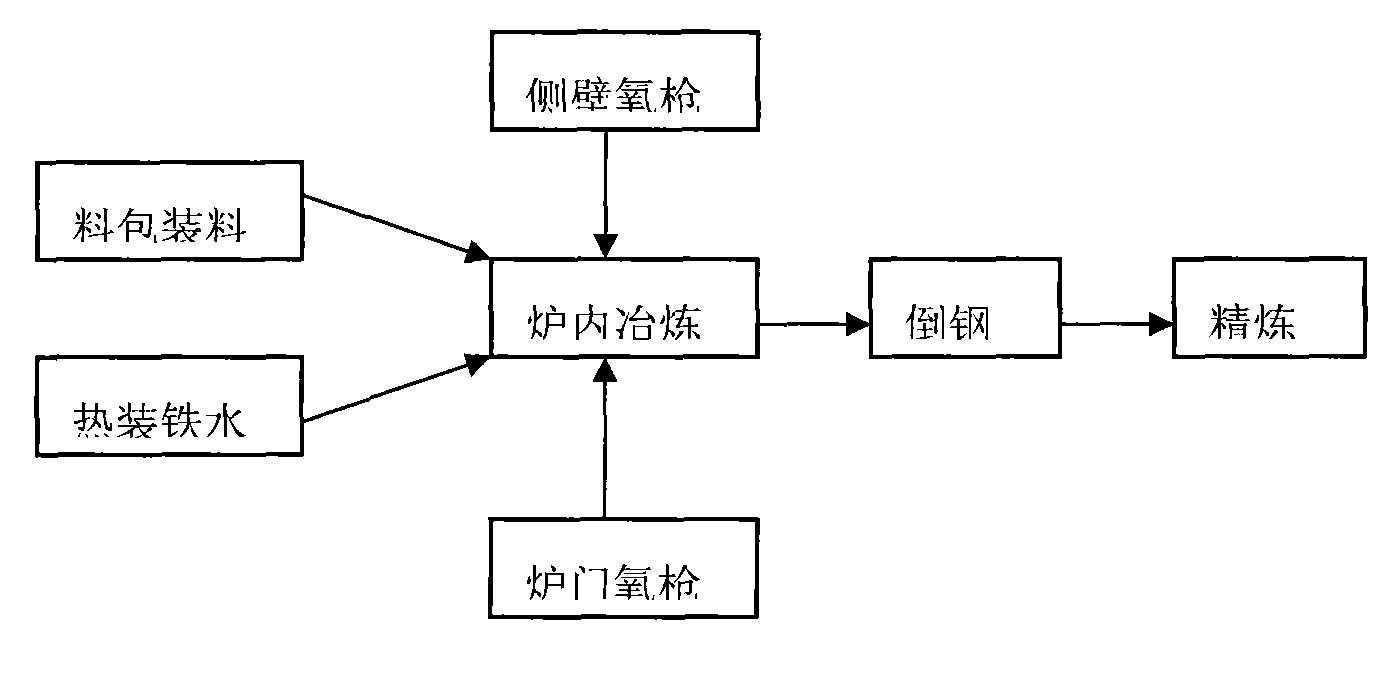

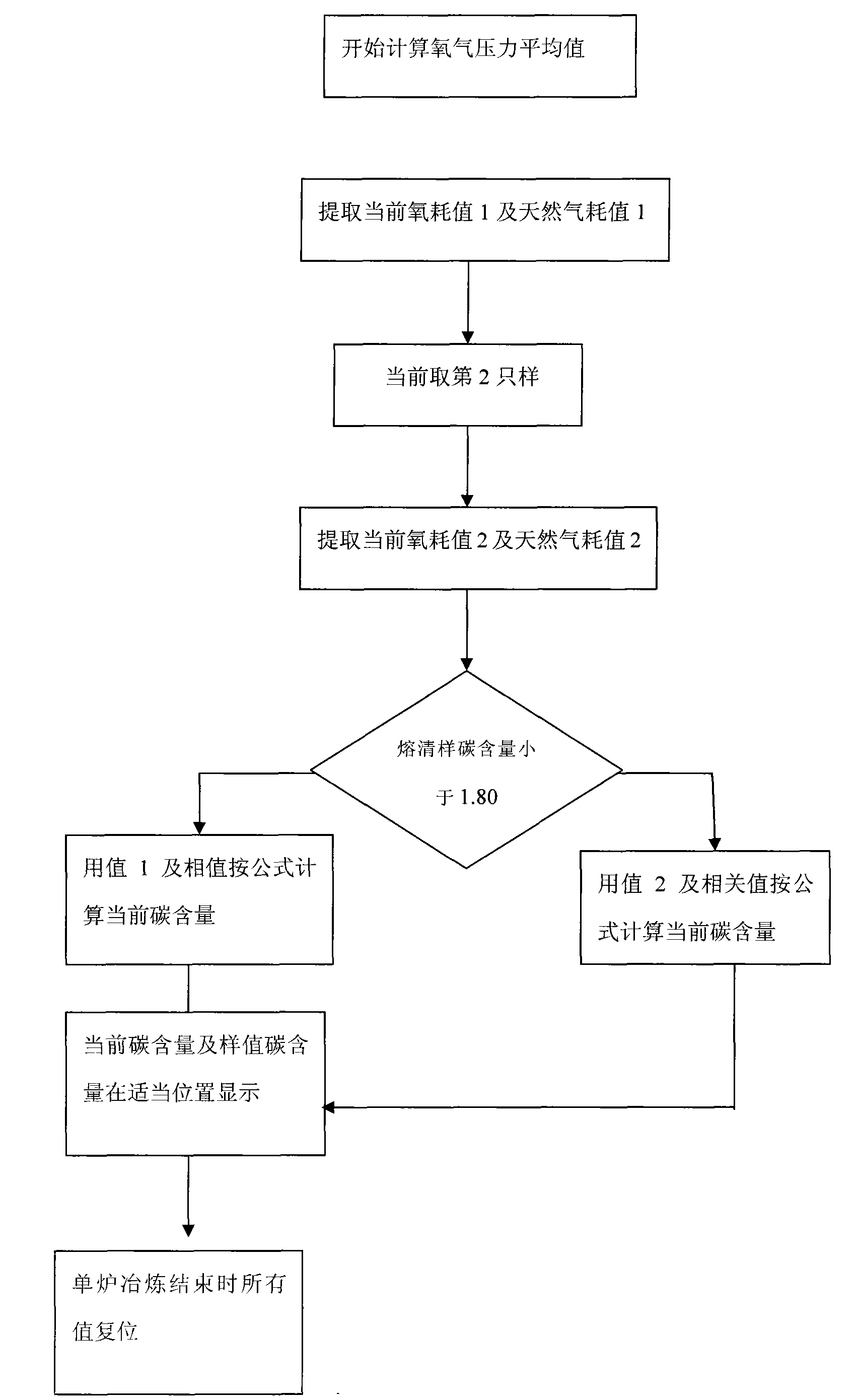

Method used

Image

Examples

Embodiment 1

[0063] Example 1: 90T electric furnace steelmaking production in the first workshop of Runzhong Steelworks of Shagang Group, furnace number 2348 in 2009, steel type C70DA, carbon content of the melted sample is 0.82%, oxygen consumption of the side wall oxygen lance when the melted sample is taken The oxygen consumption of the furnace door oxygen lance is 831 cubic meters, the natural gas consumption of the side wall oxygen lance is 291 cubic meters, and the oxygen consumption of the side wall oxygen lance is 2003 cubic meters when the second sample is also the terminal sample. The oxygen consumption of the furnace door oxygen lance is 921 cubic meters, the natural gas consumption of the side wall oxygen lance is 313 cubic meters, the actual carbon content of the second sample is 0.61%, and the calculated value calculated by this method is 0.63%;

Embodiment 2

[0064] Example 2: 90T electric furnace steelmaking production in the first workshop of Runzhong Steelworks of Shagang Group, furnace number 2351 in 2009, steel type C70DA, carbon content of the molten sample is 1.15%, oxygen consumption of the side wall oxygen lance when the molten sample is taken The oxygen consumption of the furnace door oxygen lance is 1123 cubic meters, the natural gas consumption of the side wall oxygen lance is 300 cubic meters, the oxygen consumption of the side wall oxygen lance is 2332 cubic meters when the second sample is taken, and the furnace door oxygen consumption The oxygen consumption of the lance is 1260 cubic meters, the natural gas consumption of the sidewall oxygen lance is 326 cubic meters, the actual carbon content value of the second sample is 0.83%, and the calculated value obtained by this method is 0.84%; the third sample is also The oxygen consumption of the side wall oxygen lance is 2516 cubic meters, the oxygen consumption of the f...

Embodiment 3

[0065] Example 3: 90T electric furnace steelmaking production in the first workshop of Runzhong Steelworks of Shagang Group, furnace number 2382 in 2009, steel type C80DA, the carbon content of the melted sample is 1.02%, and the oxygen consumption of the side wall oxygen lance when the melted sample is taken The oxygen consumption of the furnace door oxygen lance is 1070 cubic meters, the natural gas consumption of the side wall oxygen lance is 334 cubic meters, and the oxygen consumption of the side wall oxygen lance is 2232 cubic meters when the second sample is also the terminal sample. The oxygen consumption of the furnace door oxygen lance is 1231 cubic meters, the natural gas consumption of the side wall oxygen lance is 367 cubic meters, the actual carbon content of the second sample is 0.66%, and the calculated value obtained by this method is 0.66%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com