PDP power integration module and method for manufacturing same

A technology of power integration and manufacturing methods, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of high price, achieve the effect of high cost performance, reduce complexity, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical measure that the present invention adopts is:

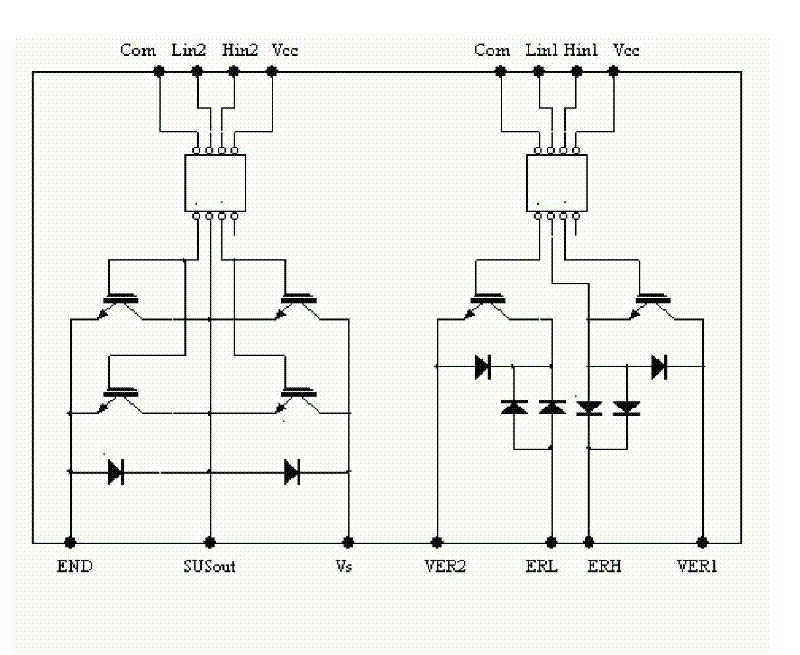

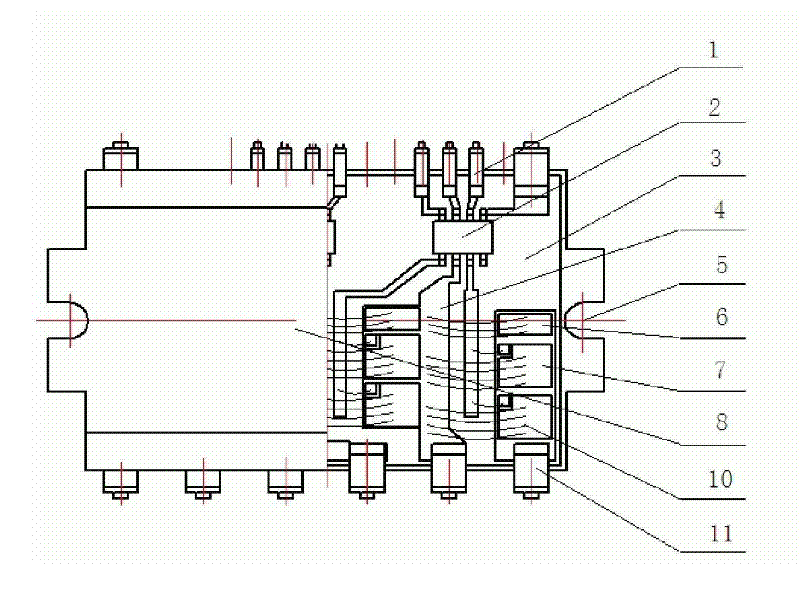

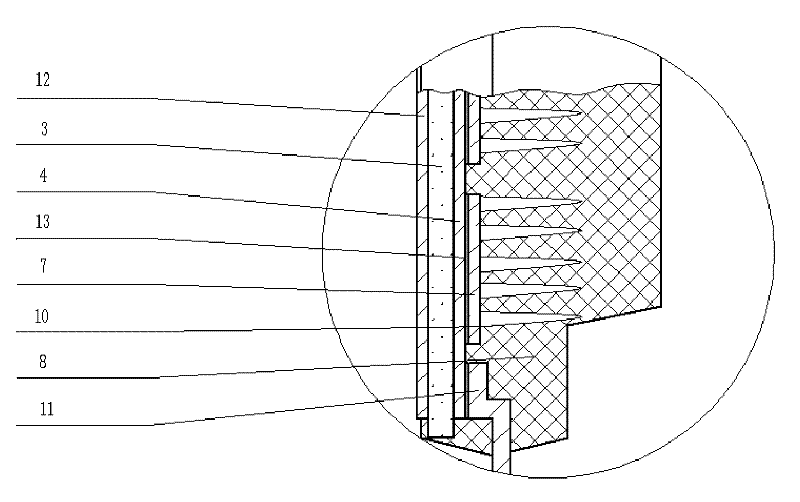

[0025] A PDP power integrated module, comprising a ceramic substrate, the ceramic substrate is provided with a copper clad layer, and the outside of the component is encapsulated with an epoxy resin plastic packaging material, and it is characterized in that the copper clad layer on the ceramic substrate is provided with a signal fixed by soldering Lead pins, power lead pins and power control circuit, the power control circuit is composed of two IGBT power topology circuits, one of which is composed of two IGBT half-bridge circuits with C and E poles not connected, and a high voltage Driven by the drive IC, the E pole of the upper arm IGBT and the C pole of the lower arm IGBT are respectively connected in series with FRDs. The other power topology circuit is composed of two IGBT standard half-bridge topologies connected with C and E poles, and another Driven by a high-voltage driver IC, the upper and lower ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com