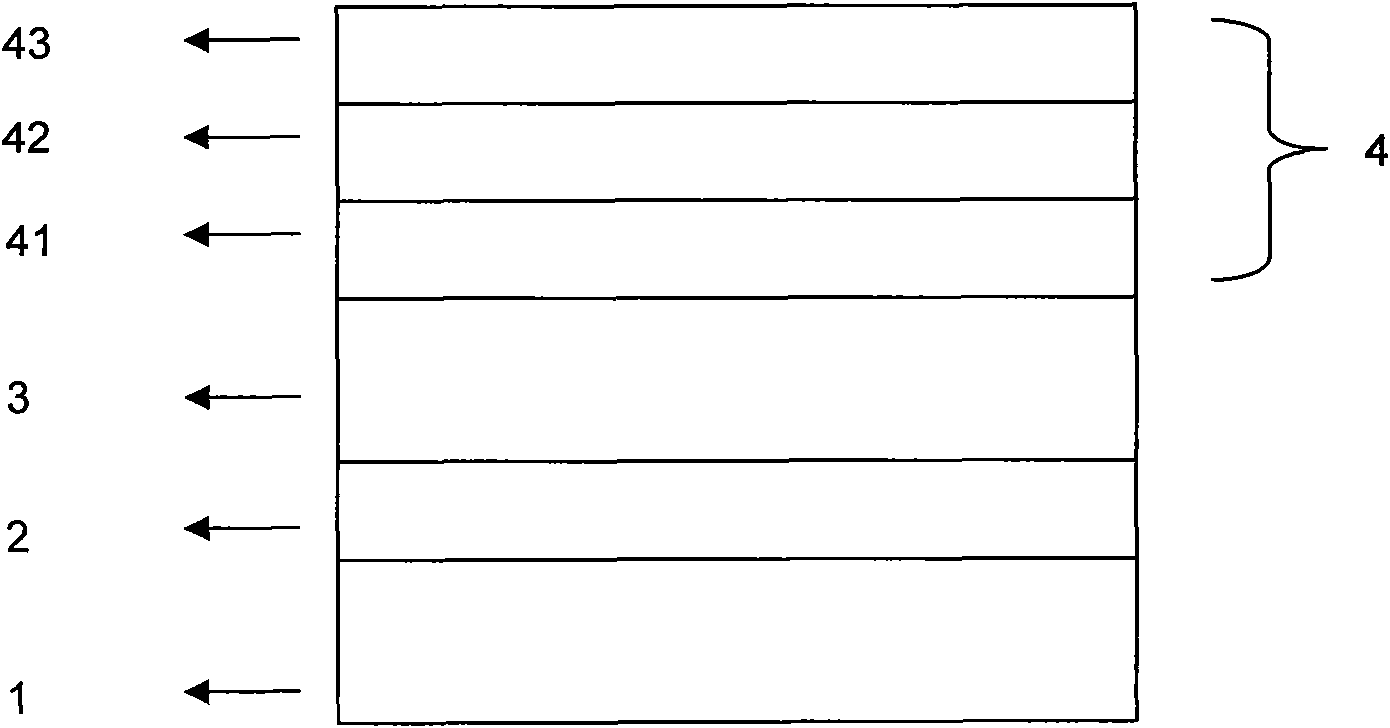

Semitransparent inverse organic solar cell and preparation method thereof

A solar cell, semi-transparent technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems that metal Al is easy to be oxidized and corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

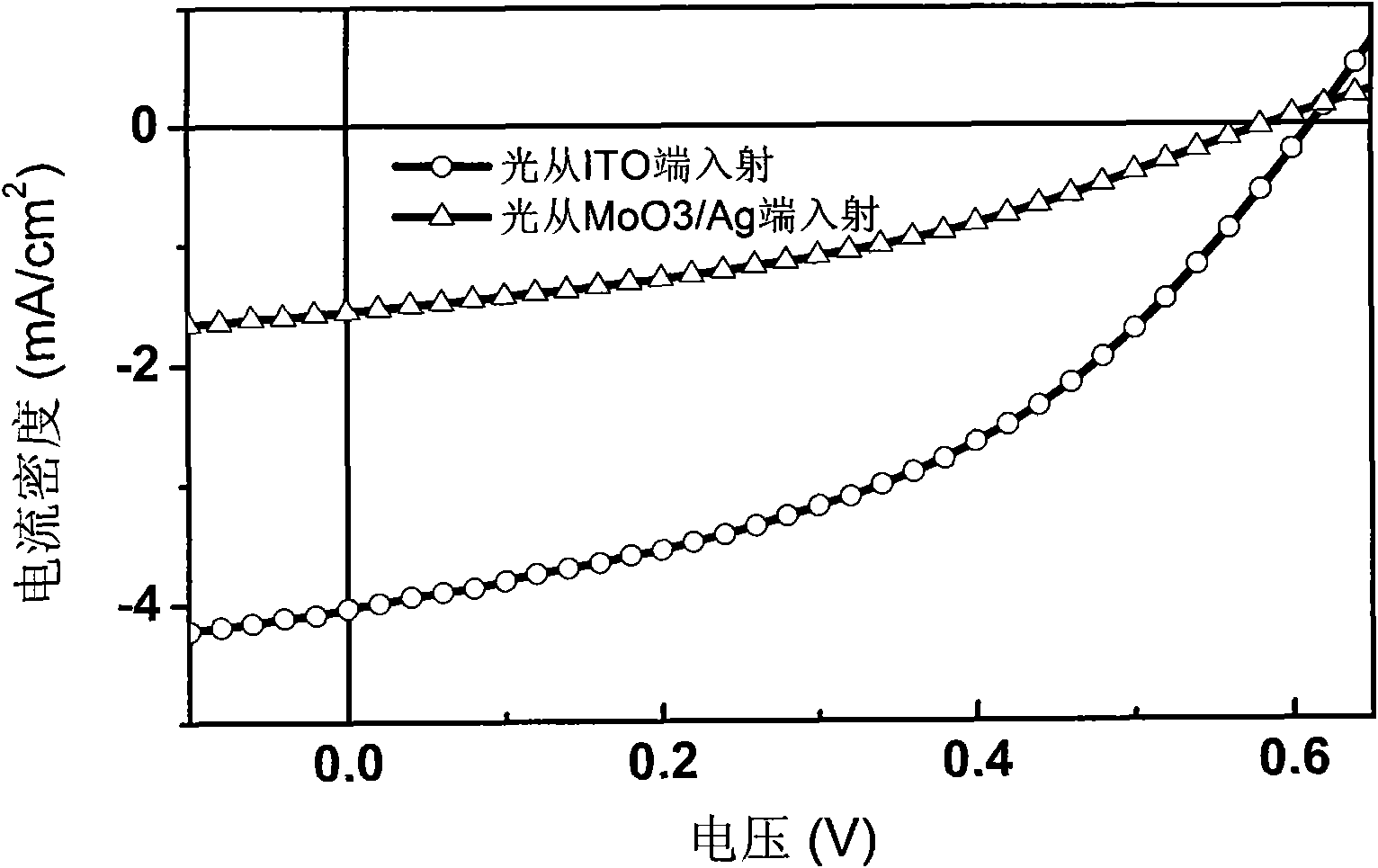

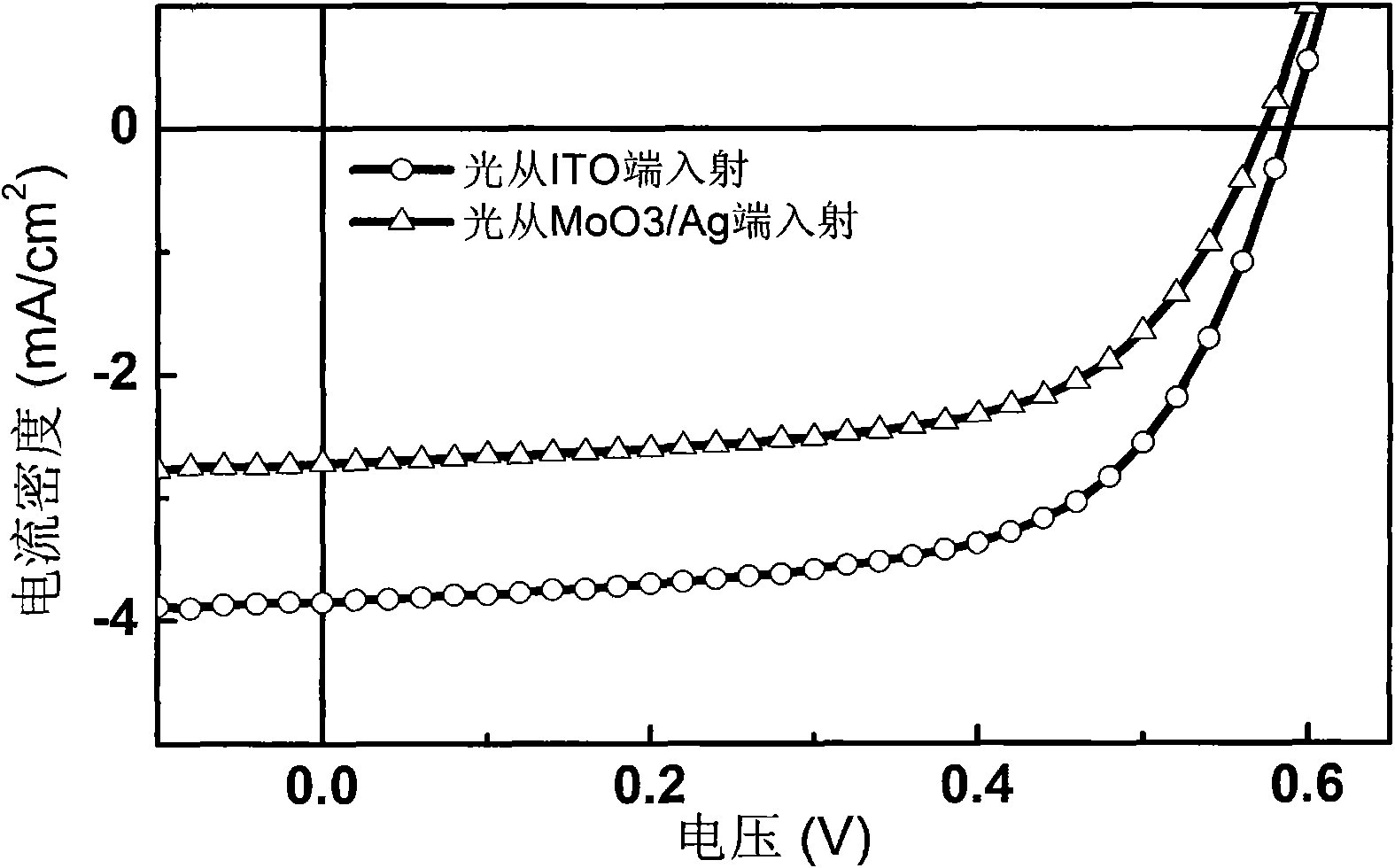

Examples

Embodiment 1

[0031] [1] The ITO glass was repeatedly scrubbed with acetone, isopropanol, and deionized water in sequence, ultrasonicated for 10 minutes, and then dried;

[0032] [2] At room temperature, add a mixed solution of 30ml of ethanol, 10ml of deionized water, and 2ml of hydrochloric acid with a concentration of 0.28mol / l dropwise into a solution containing 10ml of tetrabutyl titanate, 60ml of ethanol, and 5ml of acetylacetone , and accompanied by vigorous stirring for 2 hours, and then prepared TiO 2 Sol.

[0033] [3] TiO 2 The sol was spin-coated on the ITO glass at a speed of 3000rpm, placed in a muffle furnace, and sintered at 450°C for 2 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer with a thickness of 30 nm.

[0034][4] The chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:0.8 (concentration of 18 mg / ml) was spin-coated on ITO / nc-TiO at a speed of 1280 rpm. 2 Then put the ITO into a vacuum oven and dry it at 150° C. for 10 minutes to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com