Organic-inorganic planar heterojunction solar cell prepared through solutions and preparing method of solutions

A solution processing, solar cell technology, applied in organic semiconductor devices, sustainable manufacturing/processing, circuits, etc., can solve the problem of high cost of organic materials, improve film formation, overcome high material costs, and increase open circuit voltage and energy. The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of photoactive layer material

[0054] CH of the compound A 3 NH 3 I. CH 3 NH 3 Br, CH 3 NH 3 Cl, CH 3 CH 2 NH 3 I. CH 3 CH 2 NH 3 Br, CH 3 CH 2 NH 3 Cl, CH 3 CH 2 CH 2 NH 3 I. CH 3 CH 2 CH 2 NH 3 Br, CH 3 CH 2 CH 2 NH 3 Cl, CH(NH 2 ) 2 I, CH(NH 2 ) 2 Br, CH(NH 2 ) 2 Cl, CH 3 CH(NH 2 ) 2 I. CH 3 CH(NH 2 ) 2 Br, CH 3 CH(NH 2 ) 2 Cl. The synthesis of is prepared according to the method in the literature (J.Am.Chem.Soc.2012,134,17396-17399).

[0055] CH 3 NH 3 PB 3 The synthesis of CH 3 NH 3 I and PbI 2 It is co-dissolved in γ-butyrolactone or other organic solvents and reacted, as follows:

[0056] Take CH 3 NH 3 I (32mg) and PbI 2 (93 mg) was blended and dissolved in 1 mL of γ-butyrolactone, heated to 60° C., and stirred for 12 hours to obtain the photoactive layer material.

[0057] The preparation of photoactive layer materials containing polymer additives is as follows:

[0058] Add CH ...

Embodiment 2

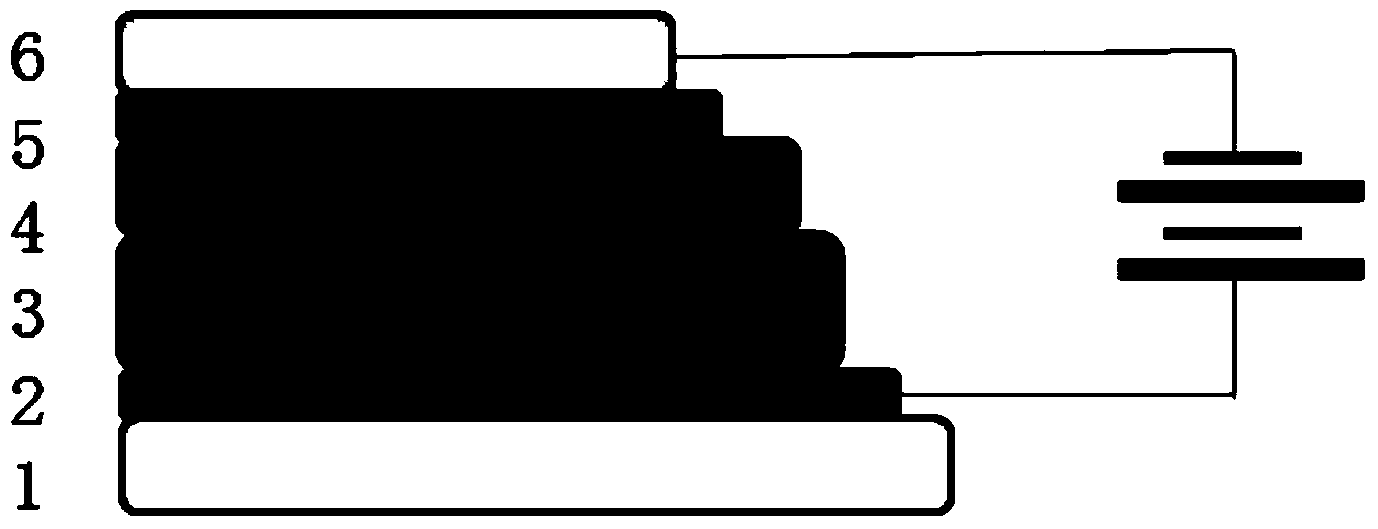

[0061] Embodiment 2: the preparation of organic-inorganic heterojunction solar cell:

[0062] Pre-cut the ITO conductive glass with a square resistance of 20 ohms / cm2 into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, and then place it in a constant temperature oven for later use after purging with nitrogen. Before use, the ITO glass slides were bombarded with plasma in an oxygen plasma etcher for 10 min. PEDOT:PSS aqueous dispersion (about 1%) was purchased from Bayer, and the buffer layer was spin-coated at a high speed using a homogenizer (KW-4A), and the thickness was determined by the solution concentration and rotating speed. 500 type) measured monitoring. After film formation, remove solvent residue and vertical film in a constant temperature vacuum oven. The film thickness of PEDOT:PSS on the ITO substrate is preferably about 40 nanometers. The cathode i...

Embodiment 3

[0069] Example 3: Photovoltaic performance of organic-inorganic heterojunction solar cells with different photoactive layer materials

[0070] CH 3NH 3 PB 3 , CH 3 NH 3 PB x Cl 3-x and CH 3 NH 3 PB x Br 3-x (x is less than 3, greater than 0) is to measure the photovoltaic performance of the organic-inorganic heterojunction solar cell prepared from the photoactive layer material, and the results are shown in Table 2.

[0071] Table 2 Battery device performance indicators of different photoactive layer materials

[0072]

Voc(V)

Jsc(mA / cm2)

FF(%)

PCE(%)

CH 3 NH 3 PB 3

0.71

7.47

44.6

2.37

CH 3 NH 3 PB x Cl 3-x

0.94

10.19

64.9

6.21

CH 3 NH 3 PB x Br 3-x

1.01

2.55

42.4

1.09

[0073] It can be seen from Table 2 that by changing the composition of the active layer material and increasing the content of bromine element or chlorine element therein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com