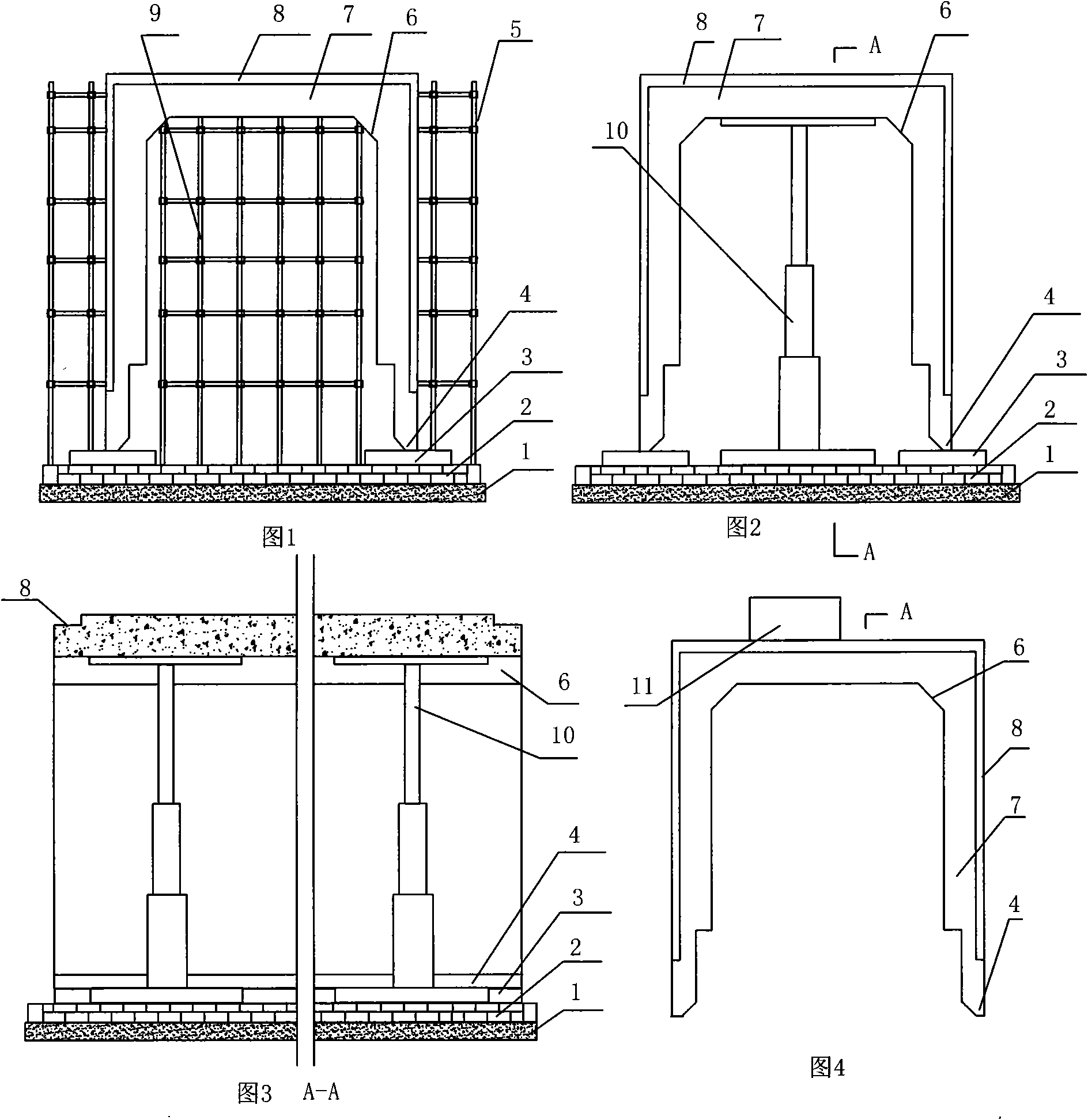

Construction method of municipal drainage culvert sinking trough

A technology of municipal drainage and construction method, which is applied in the direction of buildings and road floors, etc., can solve the problems of high cost, high demolition cost, high water level, etc., achieve good social and economic benefits, reduce construction costs, and reduce the amount of project demolition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Key technology: The key to the construction method of the present invention is to calculate the stability of the subsidence, control the subsidence speed, and control the plane displacement of the culvert to ensure smooth subsidence in place. In order to control the sinking stability and control the sinking speed, the present invention uses heavy loading or mechanical vibration to adjust, such as ballasting the parts with slow sinking speed or using a vibrator to vibrate to speed up the sinking.

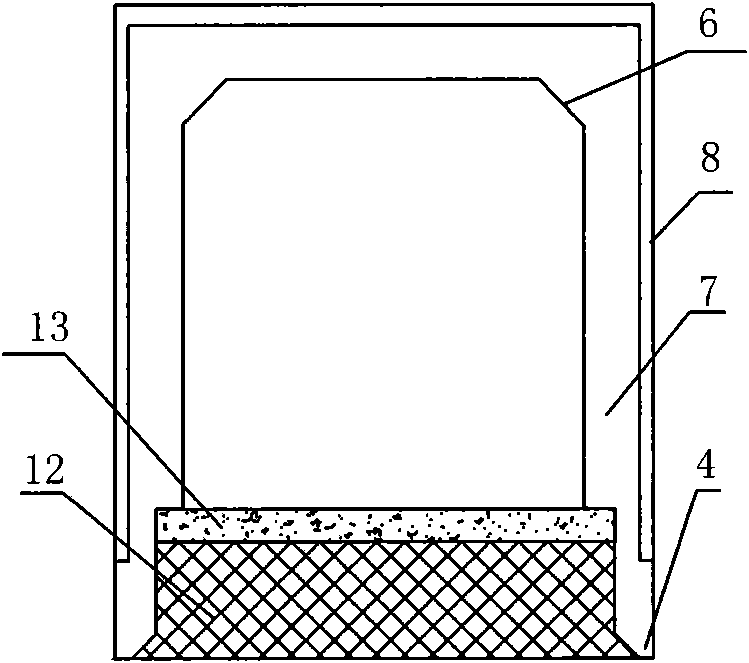

[0027] If the main body of the project is a sewage culvert, impermeable concrete should be used, and rubber waterstops must be used for horizontal construction joints. The quality of the back cover of the culvert construction must be strictly controlled to prevent sewage leakage from polluting groundwater.

[0028] Technical indicators: After the culvert sinks, there is no plane displacement, the water seepage of the culvert meets the specification requirements, there is no dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com