Method for manufacturing embedded transformer framework mounted with low-voltage coil and product

A transformer skeleton and low-voltage coil technology, which is applied in the field of transformers, can solve the problems of loose low-voltage coil mounting and unsatisfactory consistency of low-voltage coil mounting, and achieve the effect of facilitating the mounting process and avoiding the problem of force deformation and flat bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be made below in conjunction with the accompanying drawings of the embodiments.

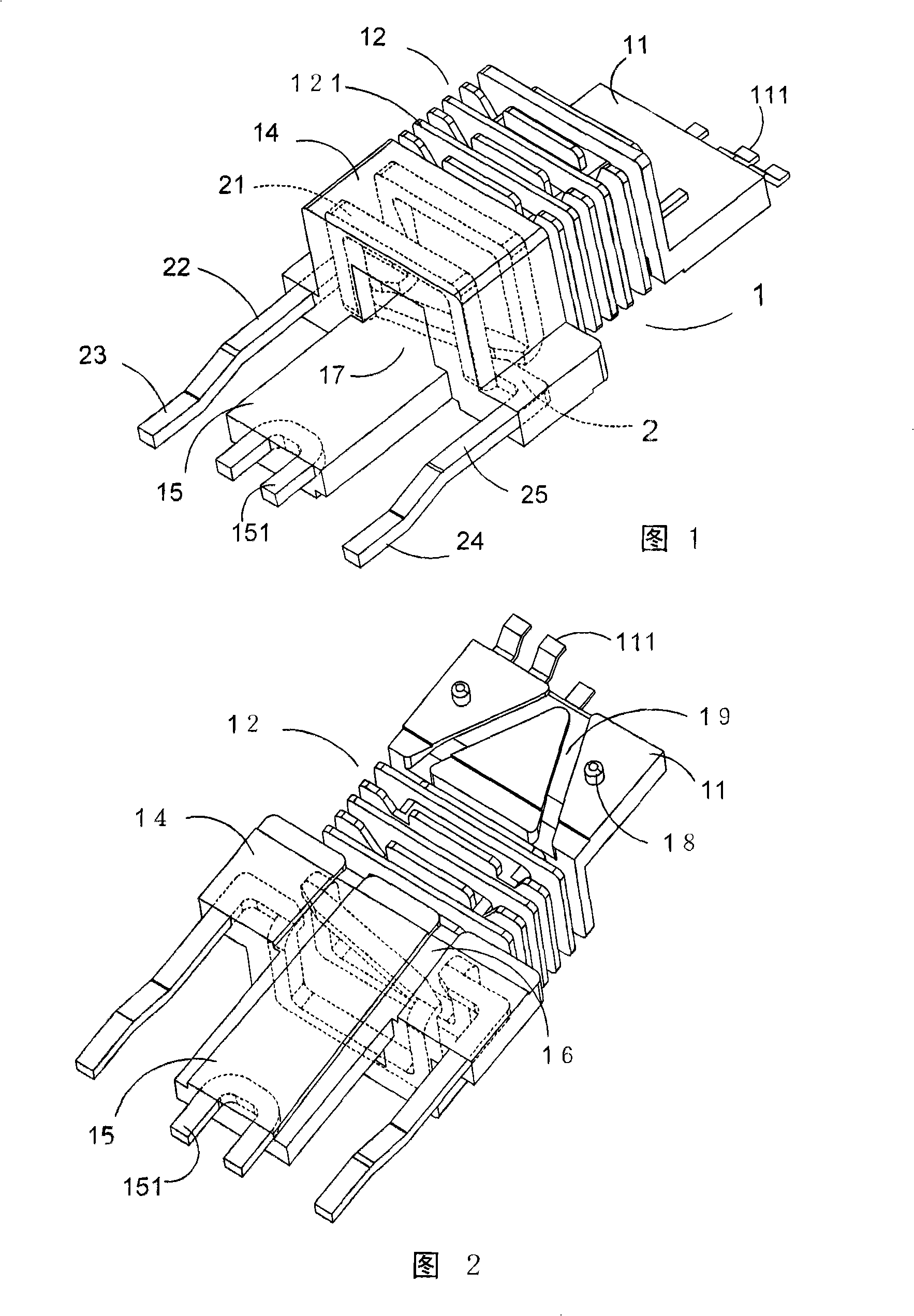

[0030] refer to Figure 1-4 , the transformer bobbin embedded with mounted low-voltage coils in this embodiment includes a plastic frame 1 and a mounted low-voltage coil 2 . The plastic frame 1 has a high-voltage coil slot 12 and a low-voltage coil area 14, and a magnetic core hole 17 is arranged inside. The first and second two pin seats 11 and 15 extend from both ends, and the first pin seat 11 is provided for connecting high-voltage wires. There are several pins 111 at one end of the coil, and the second pin base 15 is provided with pins 151 for connecting the other end of the high voltage coil.

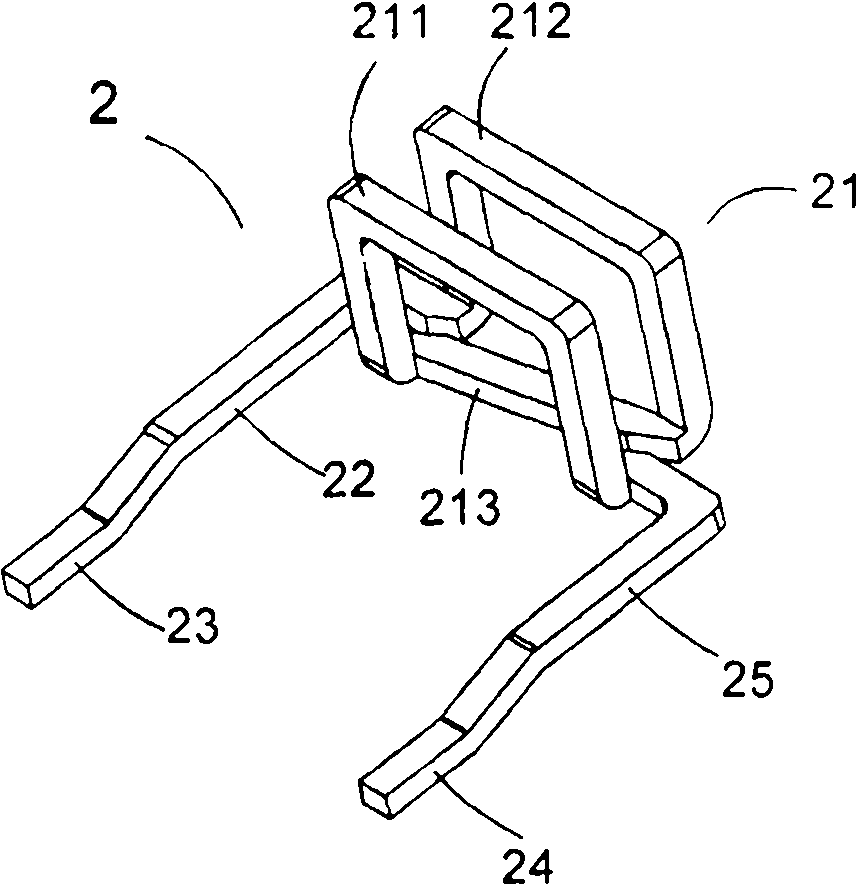

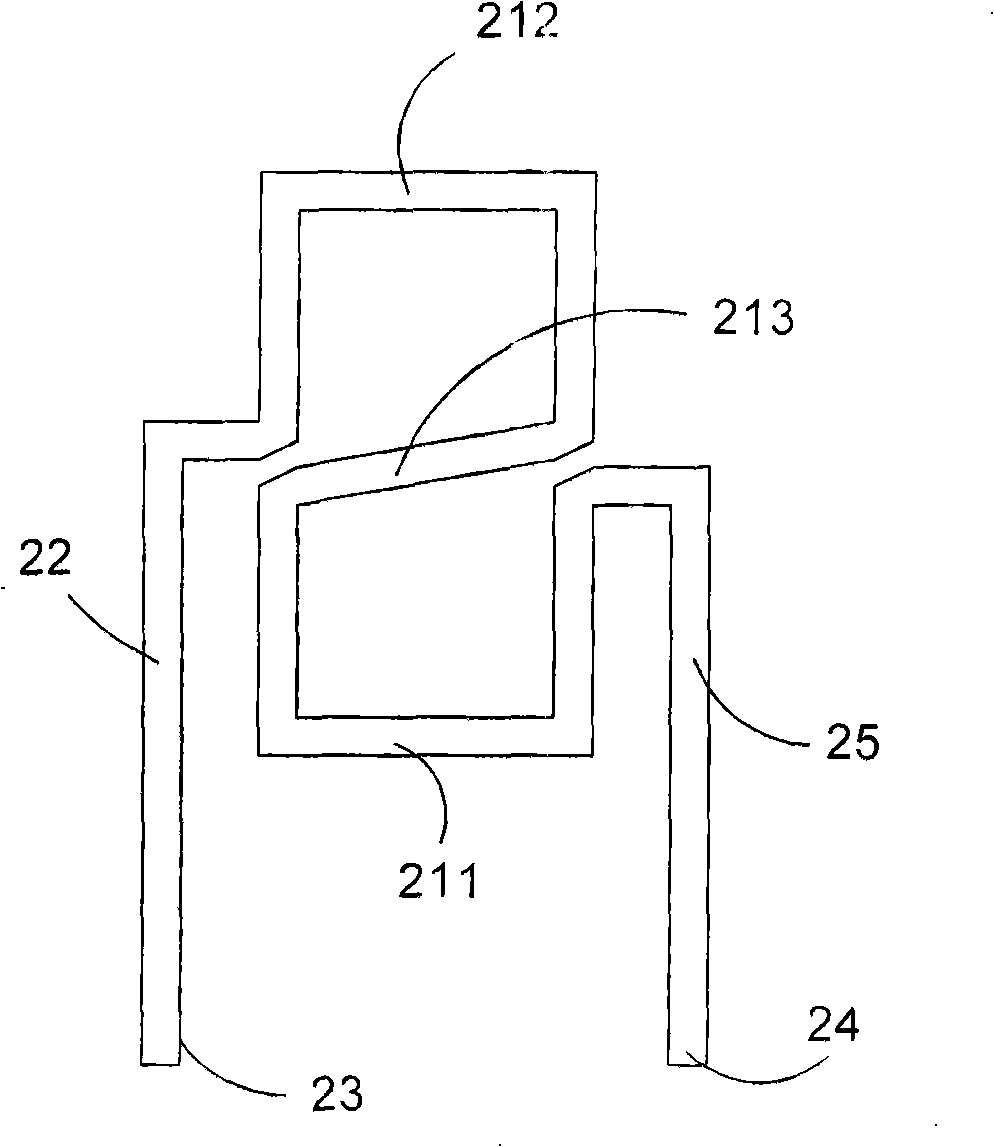

[0031] The mounted low-voltage coil 2 includes a coil part 21 and two lead-out wires 22, 25, the free ends of the two lead-out wires 22, 25 are mounting pins 23, 24 formed by die forging, and the surface is electroplated with pure bright tin; Two lead wires 22, 25 re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com