Method for pairing and lengthening steel cylinders

A pairing and cylinder technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of high production cost, high difficulty, low operation efficiency, etc., to improve the quality and work efficiency of the pairing, Efficient and safe, reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

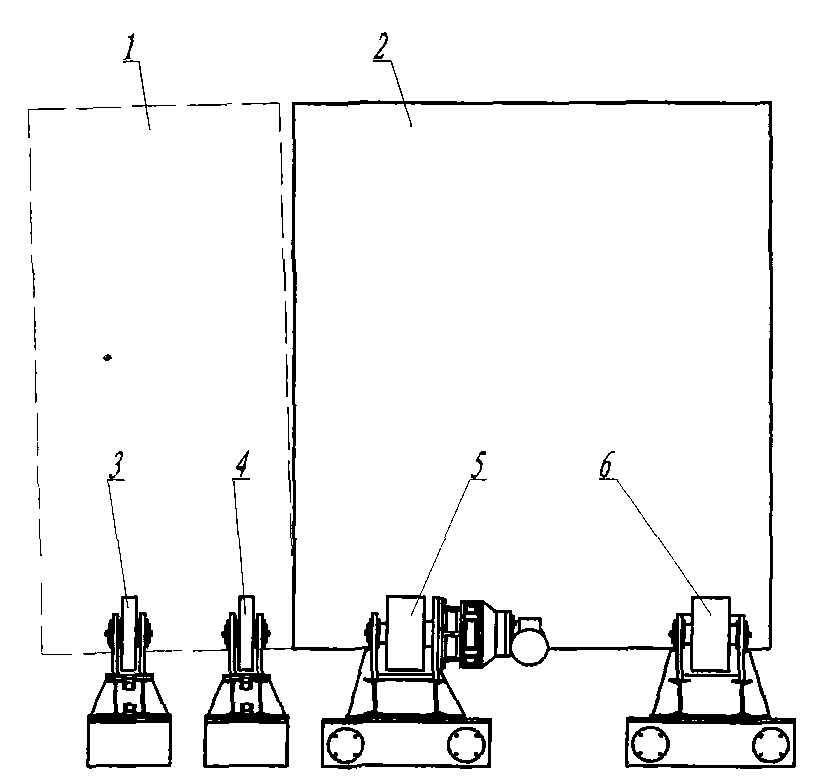

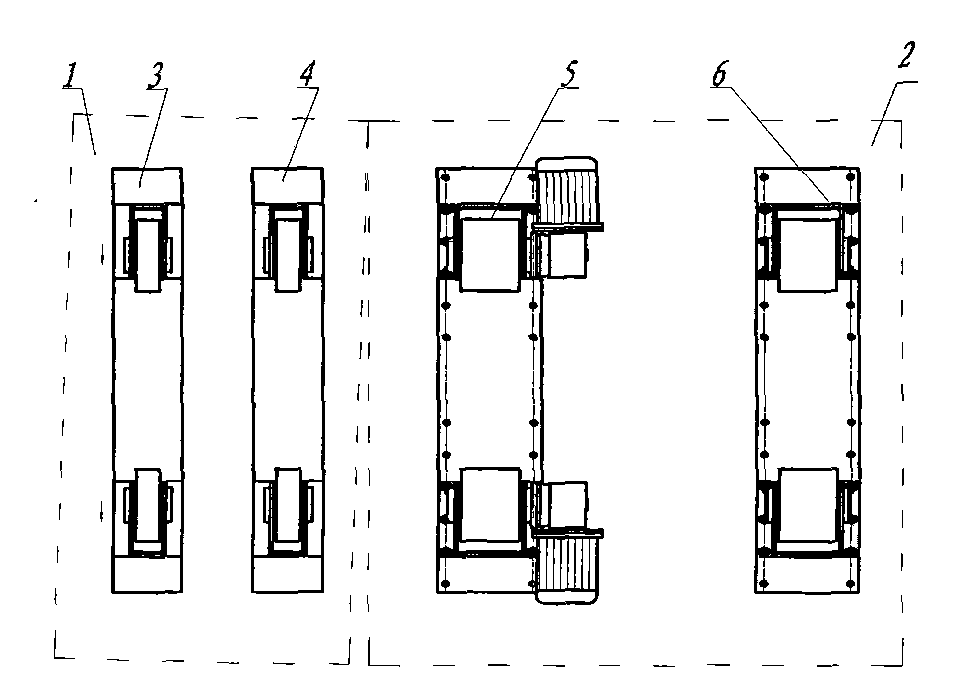

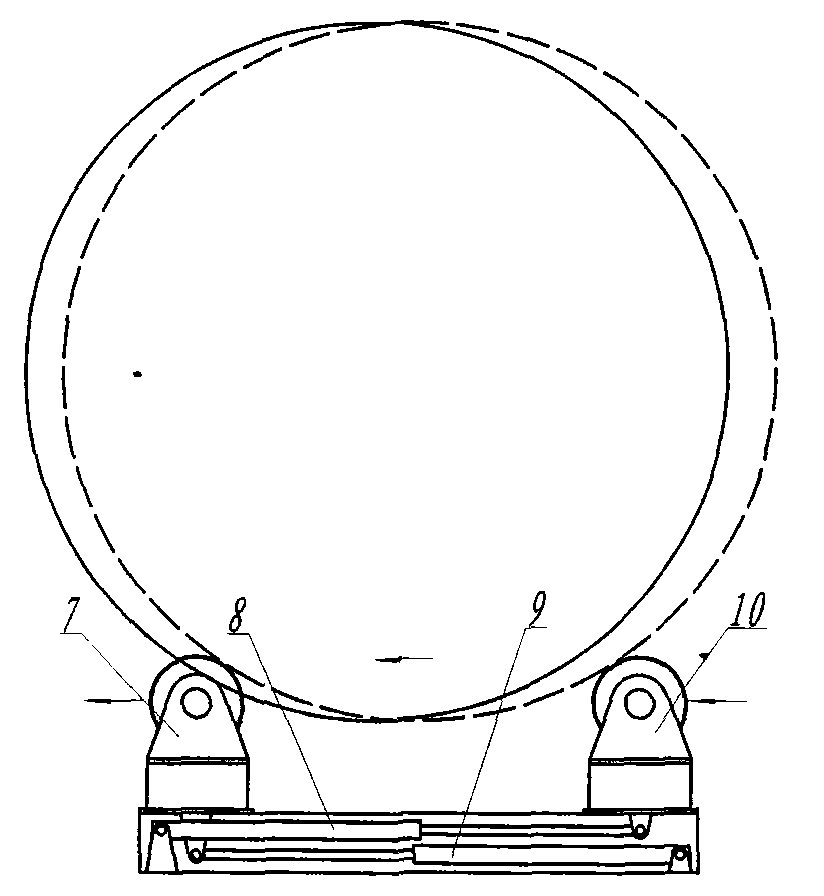

[0013] From figure 1 and figure 2 It can be seen that the pairing has been completed or the first cylinder section 2 is located on the driving roller frame 3 and the passive roller frame 4, while the cylinder section 1 to be assembled is located on the special roller frames 5 and 6 for the pairing, and the pairing points are located on the two roller frames. The lowermost side of the barrel joint.

[0014] Combine below Figure 3 to Figure 6 The specific implementation is described as follows:

[0015] 1. Preparations before group alignment

[0016] A. Generally speaking, the diameters of the outer circles at the joints of the two barrel joints to be assembled should be the same. However, since the barrel joints often have deviations during the rolling, longitudinal seam welding, etc., it is necessary to Measure the difference in circumference and calculate the amount of misalignment at the interface of the two joints, so as to avoid the quality problem of local misalignm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com