Reconfigurable cable-driven parallel manipulator and driving device thereof

A technology of flexible cable drive and drive device, applied in the directions of manipulators, program-controlled manipulators, joints, etc., can solve the problems of flexible cables falling off and ropes entangled with each other, and achieve the effect of avoiding mutual entanglement, improving efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention will be further described in detail below in conjunction with the accompanying drawings.

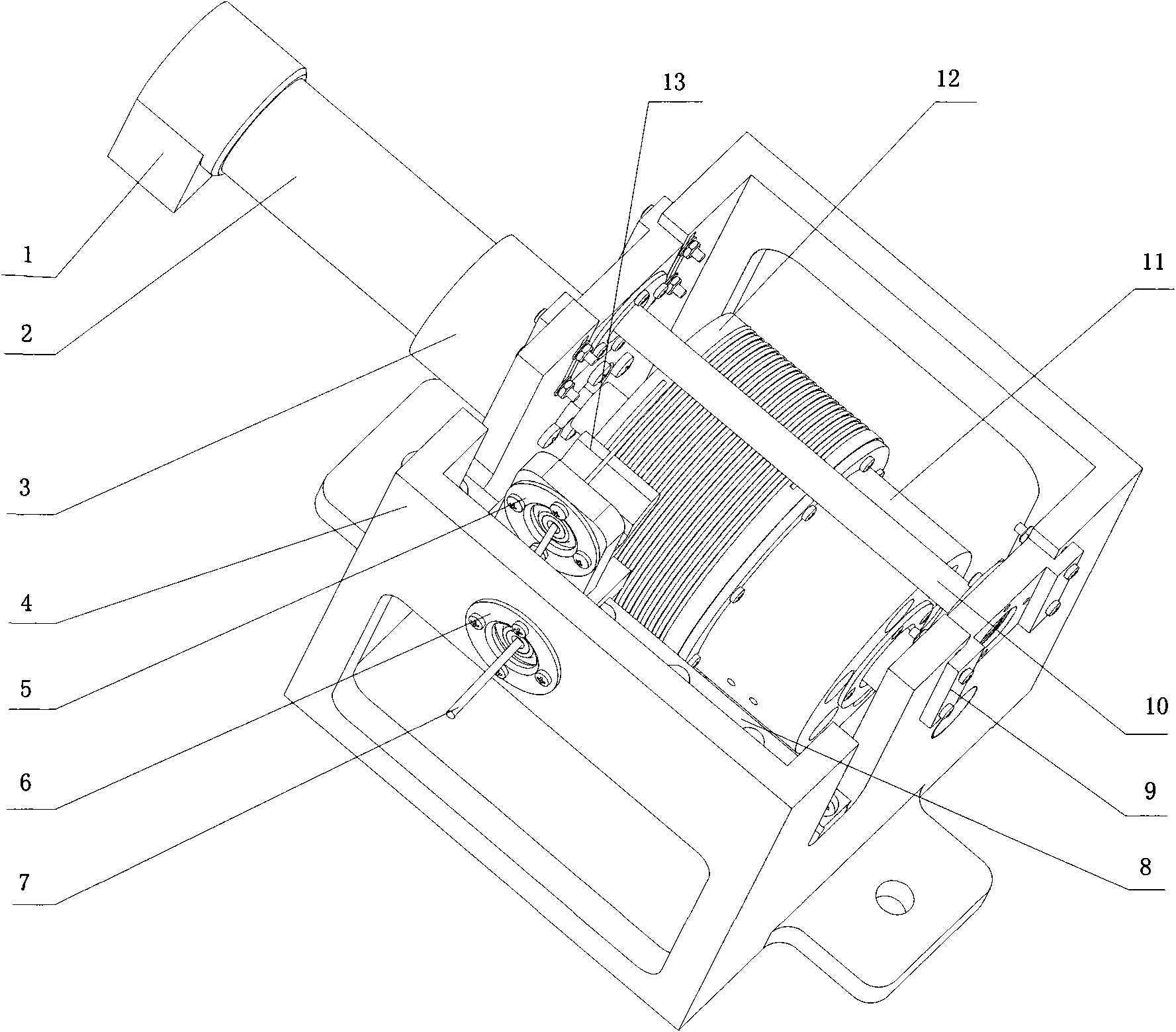

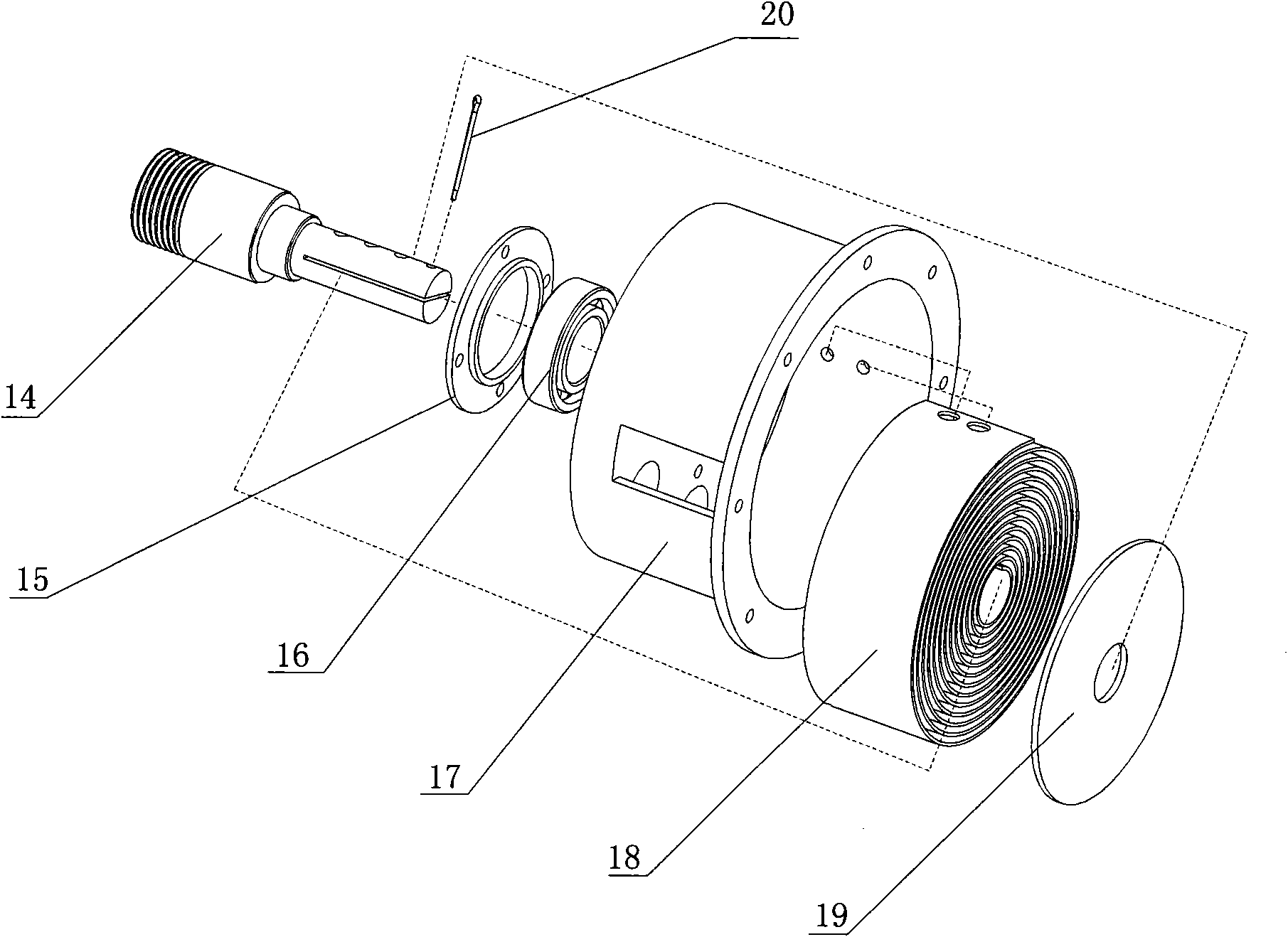

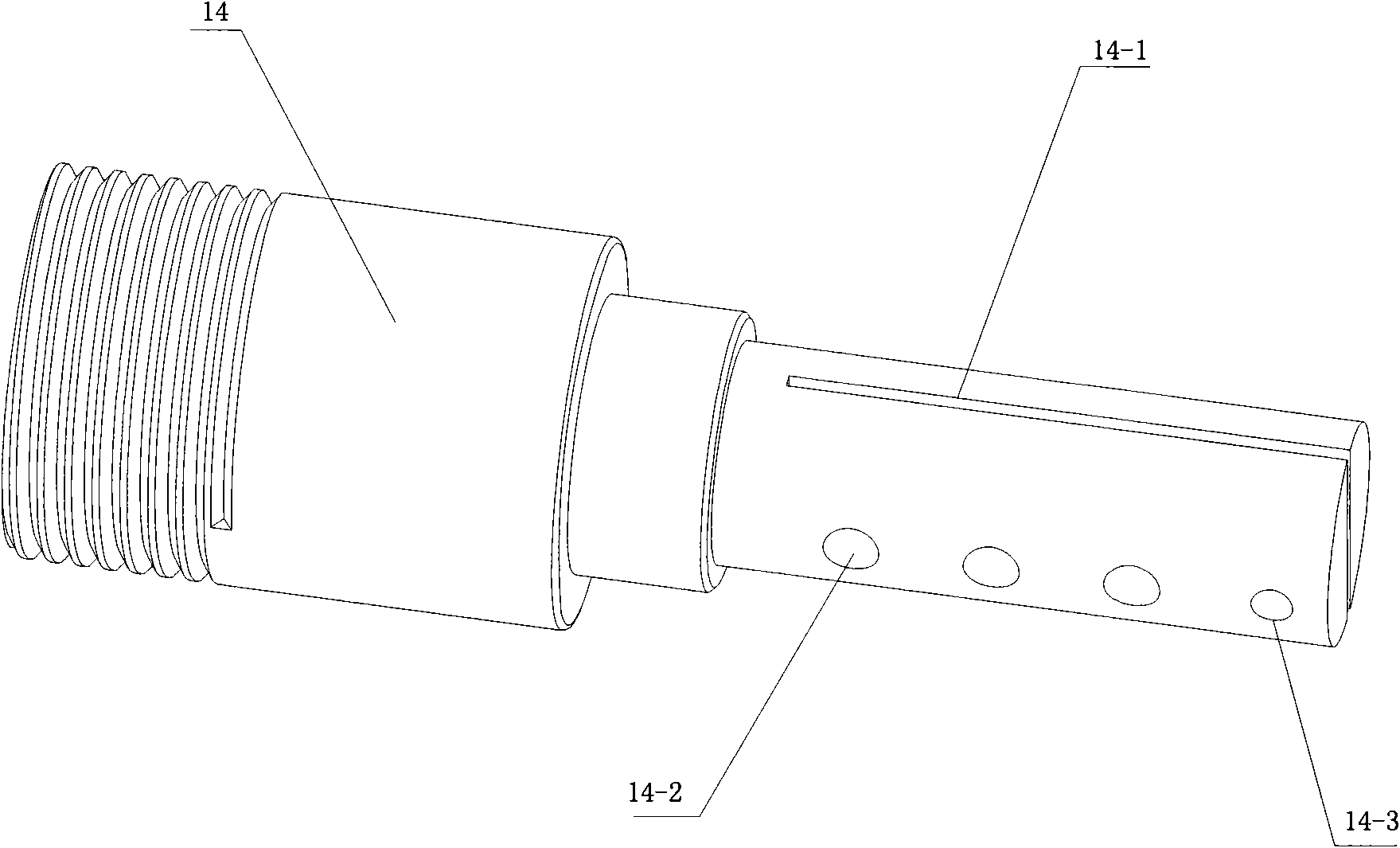

[0053] The present invention is a reconfigurable cable parallel robot and its driving module. The driving module is firstly described, and the driving module is generally divided into a winding device, a tensioning device and a transmission device. Such as figure 1 As shown in the assembly diagram of the drive module, the DC motor 2 with the reducer 3 and the encoder 1 at both ends is connected to the drive module box 4, and the drive module box 4 (such as Figure 3c Shown) is a cube box structure, and its four walls are processed with holes or grooves connected with other modules, which are the racks of various devices, such as the threaded holes of the finale supporting slide block installation groove 4-1 and the spring reel 14 4-2, linear guide rail installation groove 4-3, outer spherical guide hole installation groove 4-4, motor installation hole 4-5, in additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com