Purple perilla step-by-step extracting method and application of obtained extract in cigarette

An extraction method and extract technology, applied in the field of cigarette flavors and fragrances, can solve problems such as the inability to solve the negative effects of cigarettes, and achieve good development prospects, high safety, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

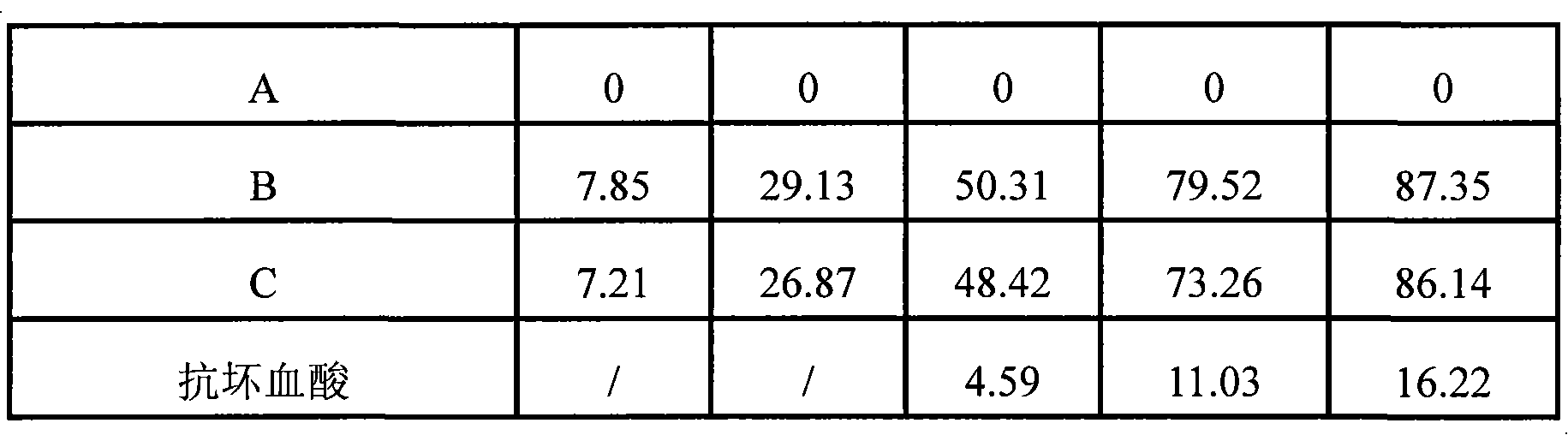

Embodiment 1

[0044] (1) Pulverize perilla leaves into coarse powder, add distilled water (perilla leaves:water=1:12, weight ratio) to the perilla leaf coarse powder, and soak at room temperature for 16 hours.

[0045] (2) Carry out steam distillation to extract volatile oil with the mixed material liquid after soaking, the extraction temperature is 120 ℃, the time is 6 hours, obtains light yellow clear and transparent oily thing, it is dissolved in the 70% ethanol of 100 times of weight, Extract A is obtained.

[0046] (3) Filtrating the perilla mixed material liquid after extracting the volatile oil to obtain a filtrate. Add distilled water 10 times the weight of the original medicinal material to the filter residue, carry out reflux extraction at a temperature of 120° C. for 3 hours, filter, and combine the two filtrates.

[0047] (4) Take half the weight of the filtrate and concentrate it to a solution equivalent to 1.0 g / ml of the original medicinal material at a temperature of 65° C....

Embodiment 2

[0050] (1) Pulverize perilla leaves into coarse powder, add distilled water (perilla leaves:water=1:10, weight ratio) to the perilla leaf coarse powder, and soak at room temperature for 18 hours.

[0051] (2) steam distilling and extracting volatile oil from the mixed material liquid after soaking, the extraction temperature is 120 DEG C, and the time is 8 hours to obtain light yellow clear and transparent oil, which is dissolved in 70% ethanol of 100 times of weight, Extract A is obtained.

[0052] (3) Filtrating the perilla mixed material liquid after extracting the volatile oil to obtain a filtrate. Add distilled water 8 times the weight of the original medicinal material to the filter residue, carry out reflux extraction at a temperature of 120° C. for 3 hours, filter, and combine the two filtrates.

[0053] (4) Take half the weight of the filtrate and concentrate it to a solution equivalent to 1.0 g / ml of the original medicinal material at a temperature of 65° C. and a v...

Embodiment 3

[0056] (1) Pulverize perilla leaves into coarse powder, add distilled water (perilla leaves:water=1:12, weight ratio) to the perilla leaf coarse powder, and soak at room temperature for 18 hours.

[0057] (2) Carry out steam distillation to extract volatile oil with the mixed material liquid after soaking, the extraction temperature is 120 ℃, the time is 10 hours, obtains light yellow clear and transparent oily thing, it is dissolved in the 70% ethanol of 100 times of weight, Extract A is obtained.

[0058] (3) Filtrating the perilla mixed material liquid after extracting the volatile oil to obtain a filtrate. Add distilled water 10 times the weight of the original medicinal material to the filter residue, carry out reflux extraction at a temperature of 120° C. for 3 hours, filter, and combine the two filtrates.

[0059] (4) Take half the weight of the filtrate and concentrate it to a solution equivalent to 1.0 g / ml of the original medicinal material at a temperature of 68° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com