High-speed industrial sewing machine control system based on CPU and FPGA structures

A technology of industrial sewing machines and control systems, which is applied in the direction of sewing machine control devices, program-controlled sewing machines, sewing machine components, etc., can solve the problems of high price, unsatisfactory sewing effect, and slow speed, and achieve low price and lighten the load , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

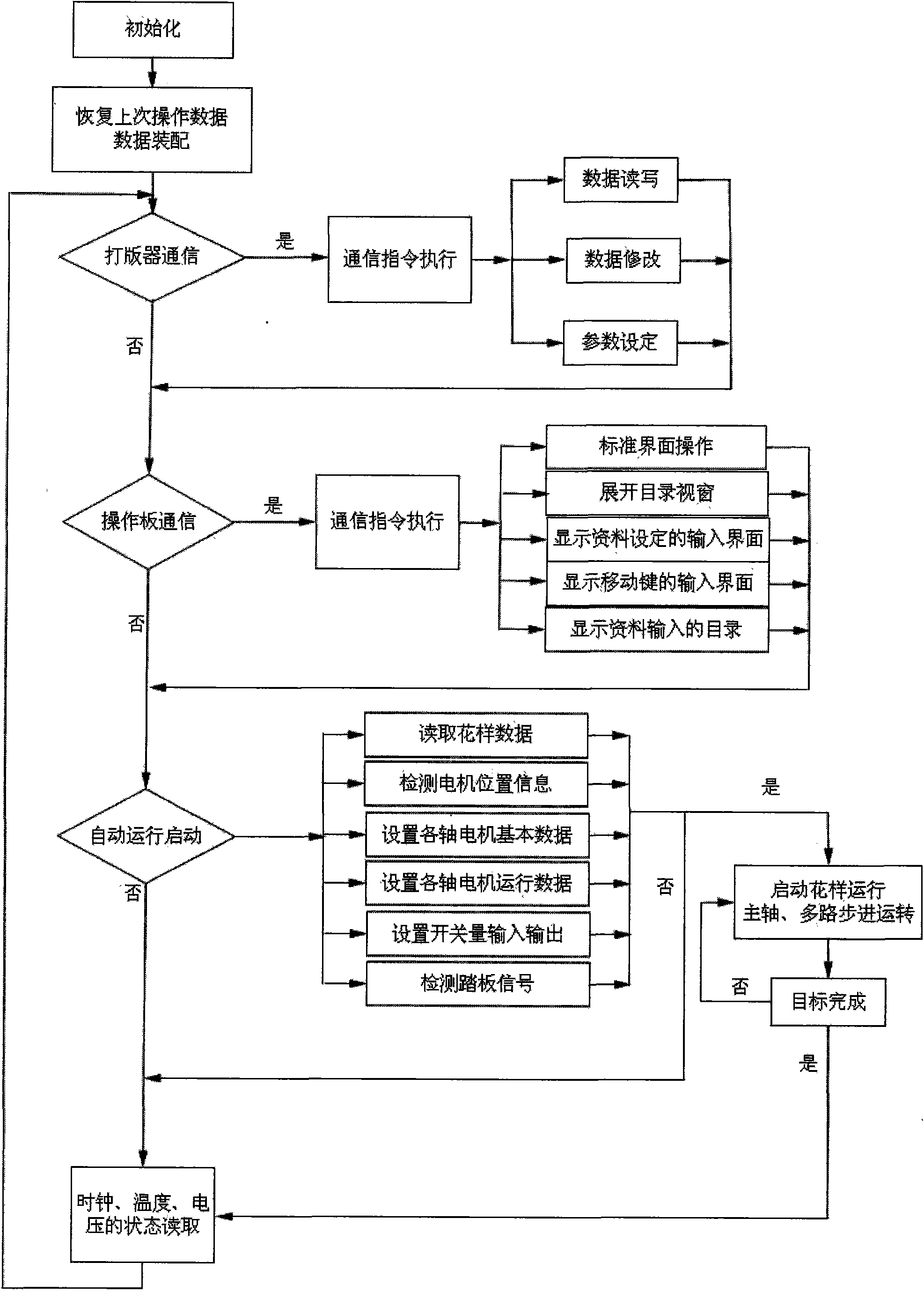

[0015] The high-speed industrial sewing machine control system with multi-CPU structure of the present invention will be further described through specific embodiments and accompanying drawings.

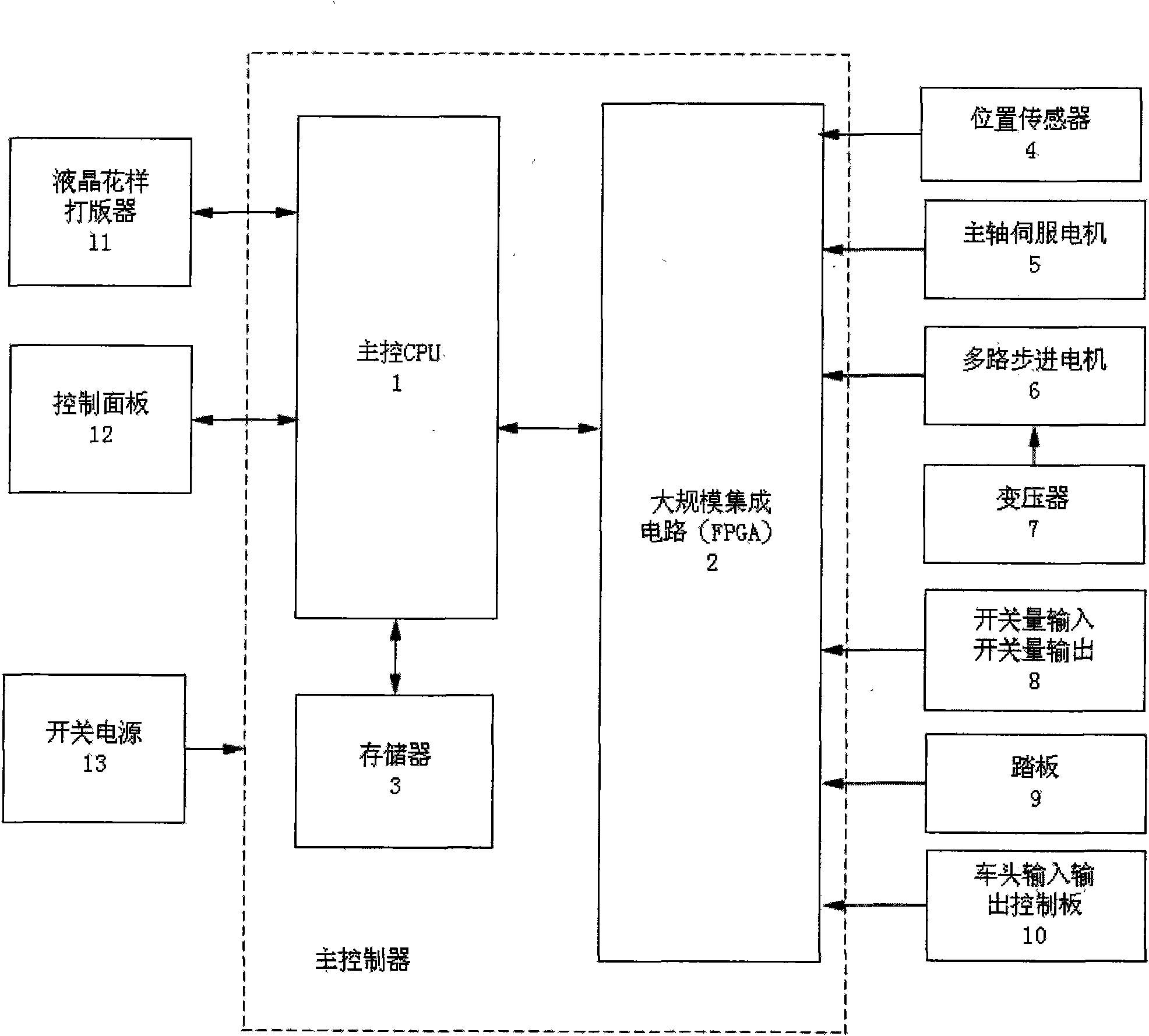

[0016] A kind of high-speed industrial sewing machine control system based on CPU and FPGA structure of the present invention comprises:

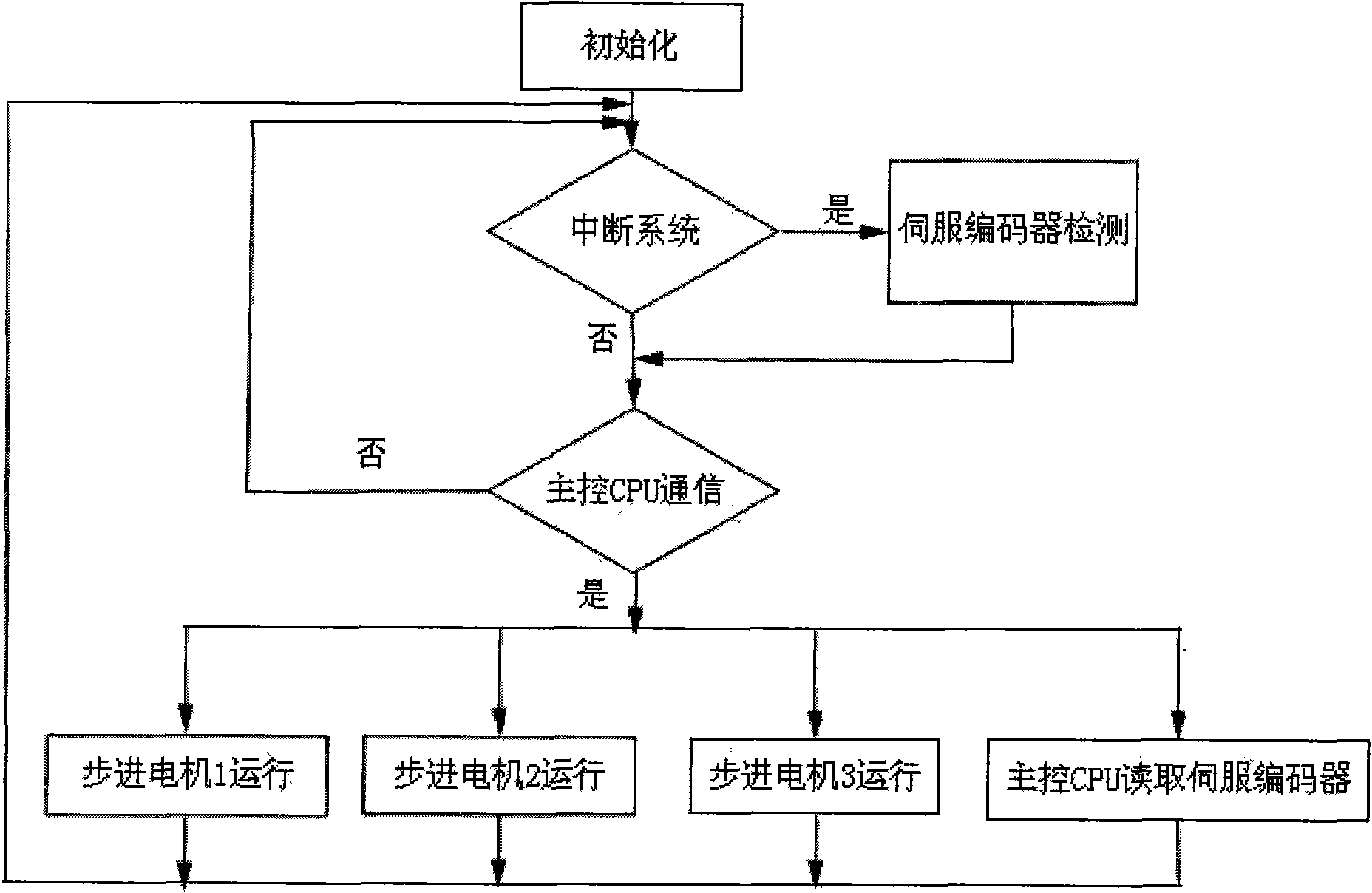

[0017] A main control CPU (1), a large-scale integrated circuit FPGA (2), a front input and output control board (10) and a liquid crystal pattern maker (11) form the control unit of the present invention. The control unit is the core of the system. The main control CPU (1) adopts a 32-bit microcontroller. The CPU core contains Flash memory, RAM memory and internal bus accelerator architecture, etc., and realizes the requirements of the main control CPU (1) from the hardware. for fast calculation purposes. Large-scale integrated circuit FPGA (2) adopts Flash architecture, which has the characteristics of high security, running after power-on, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com