Tail gas processing system and method for anode of fuel cell

A technology for anode tail gas and fuel cells, applied in fuel cells, chemical instruments and methods, electrical components, etc., can solve environmental pollution and other problems, and achieve the effects of convenient use, mild reaction conditions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples.

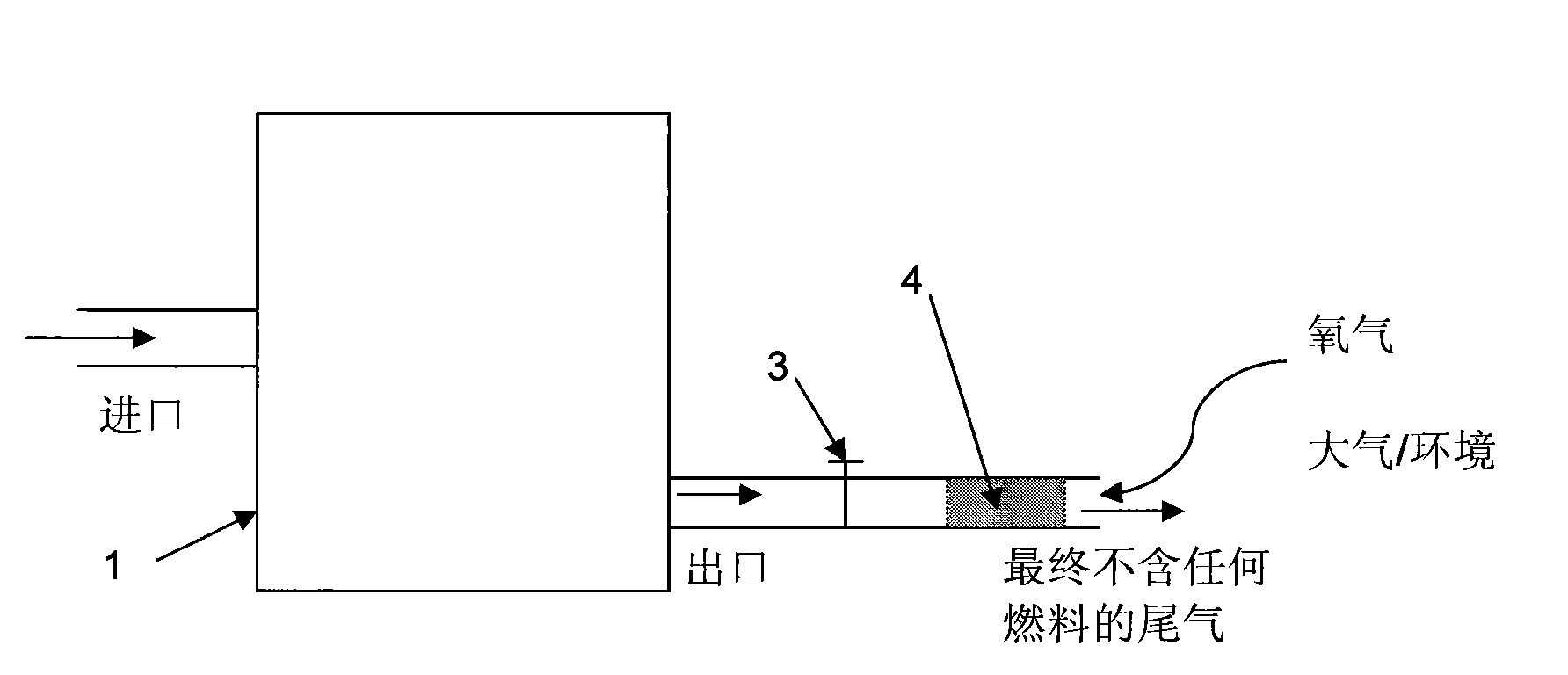

[0033] Such as image 3 Shown, is a kind of simplest embodiment of the present invention, is applicable to the situation that anode exhaust gas outlet is closed most of the time. The basic point of this scheme is that the exhaust gas that controls exhaust gas discharge is installed on the anode exhaust gas outlet pipeline of electric stack 1 The valve 3 is also equipped with a catalytic oxidation catalyst 4 on the outlet pipe of the exhaust valve, which is used to realize the catalytic oxidation reaction between the fuel in the exhaust gas and the oxygen in the air to oxidize the fuel. When the exhaust valve 3 at the outlet of the anode exhaust gas is closed, the oxygen in the surrounding atmospheric environment will diffuse into the exhaust pipe. The remaining oxygen undergoes an oxidation reaction to consume the fuel, so that the final exhaust gas without any fuel is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com