Method and device for preparing iron nitride material by double promotion of nanocrystallization and strong magnetic field

A strong magnetic field, iron nitride technology, applied in the direction of nitrogen-metal/silicon/boron binary compounds, etc., can solve the problems of inability to carry out the nitridation reaction and difficulty in the preparation of α″-Fe, and achieve the effect of inhibiting the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

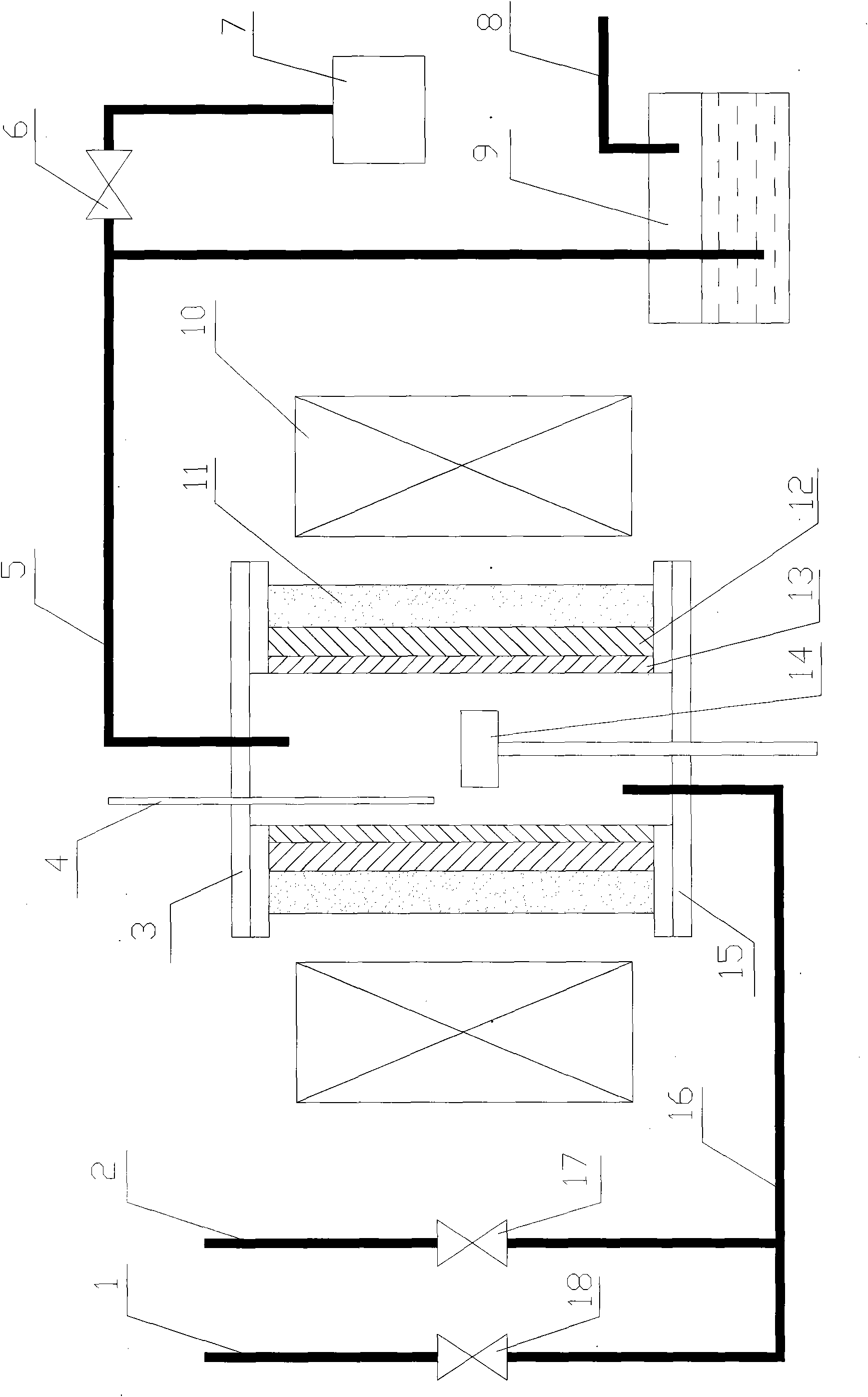

[0021] The method of preparing the iron nitride material is as follows.

[0022] High-purity iron powder (purity ≥ 99.9%) is used as a raw material, and the powder is ball-milled for 25 hours with a high-energy ball mill to obtain iron powder with a grain diameter of 8 nm.

[0023] The prepared nanometer pure iron powder is loaded into the material container in the reactor of the high magnetic field gas nitriding furnace. Introduce hydrogen, control the space velocity to 0.5h -1 , kept at 400°C for 60 minutes, then stopped heating, and cooled naturally to 80°C. At this temperature, a 12T magnetic field is applied by a magnetic field generator, and ammonia gas is introduced at the same time, and the space velocity is controlled to be 0.5h -1 , raise the temperature in the reactor to 180°C and keep it warm for 15 hours, then cool it naturally to room temperature to obtain iron nitride powder, which can be known by X-ray analysis, in which α″-Fe 16 N 2 The composition is abou...

Embodiment 2

[0026] The method of preparing the iron nitride material is as follows.

[0027] High-purity iron powder (purity ≥ 99.9%) is used as a raw material, and the powder is ball-milled for 10 hours with a high-energy ball mill to obtain iron powder with a grain diameter of 50 nm.

[0028] The prepared nano-iron powder is loaded into a material container in a reactor of a strong magnetic field gas nitriding furnace. Introduce hydrogen, control the space velocity to 5h -1 , kept at 450°C for 15 minutes, then stopped heating, and cooled naturally to 60°C. At this temperature, a 20T magnetic field is applied by a magnetic field generator, and ammonia gas is introduced at the same time, and the space velocity is controlled to be 5h -1, raising the temperature in the reactor to 120° C. and keeping it warm for 30 hours, and then naturally cooling to room temperature to obtain an iron nitride powder product. It can be known by X-ray analysis that α″-Fe 16 N 2 The ingredients account fo...

Embodiment 3

[0031] The method of preparing the iron nitride material is as follows.

[0032] Magnetite powder with an average diameter of 30nm is used as raw material. The magnetite powder is loaded into the material container in the high magnetic field gas nitriding furnace reactor. Introduce hydrogen, control the space velocity to 3h -1 , kept at 300°C for 90 minutes, then stopped heating, and cooled naturally to 100°C. At this temperature, a magnetic field of 6T is applied by the magnetic field generator, and ammonia gas is introduced at the same time, and the space velocity is controlled to be 3h -1 , raising the temperature in the reactor to 250° C. and keeping it warm for 8 hours, and then naturally cooling to room temperature to obtain an iron nitride powder product. It can be known by X-ray analysis that α″-Fe 16 N 2 The composition is about 75%.

[0033] During the nitriding reaction process, the ammonia decomposition rate in the furnace is detected by an ammonia decomposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com