Method and device for united production of industrial level and food level liquid carbon dioxide

A technology of liquid carbon dioxide and liquid carbon dioxide, which is applied in the field of co-production and installation of industrial-grade and food-grade liquid carbon dioxide, can solve the problems of troublesome operation and control, complicated process and unstable carbon monoxide content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

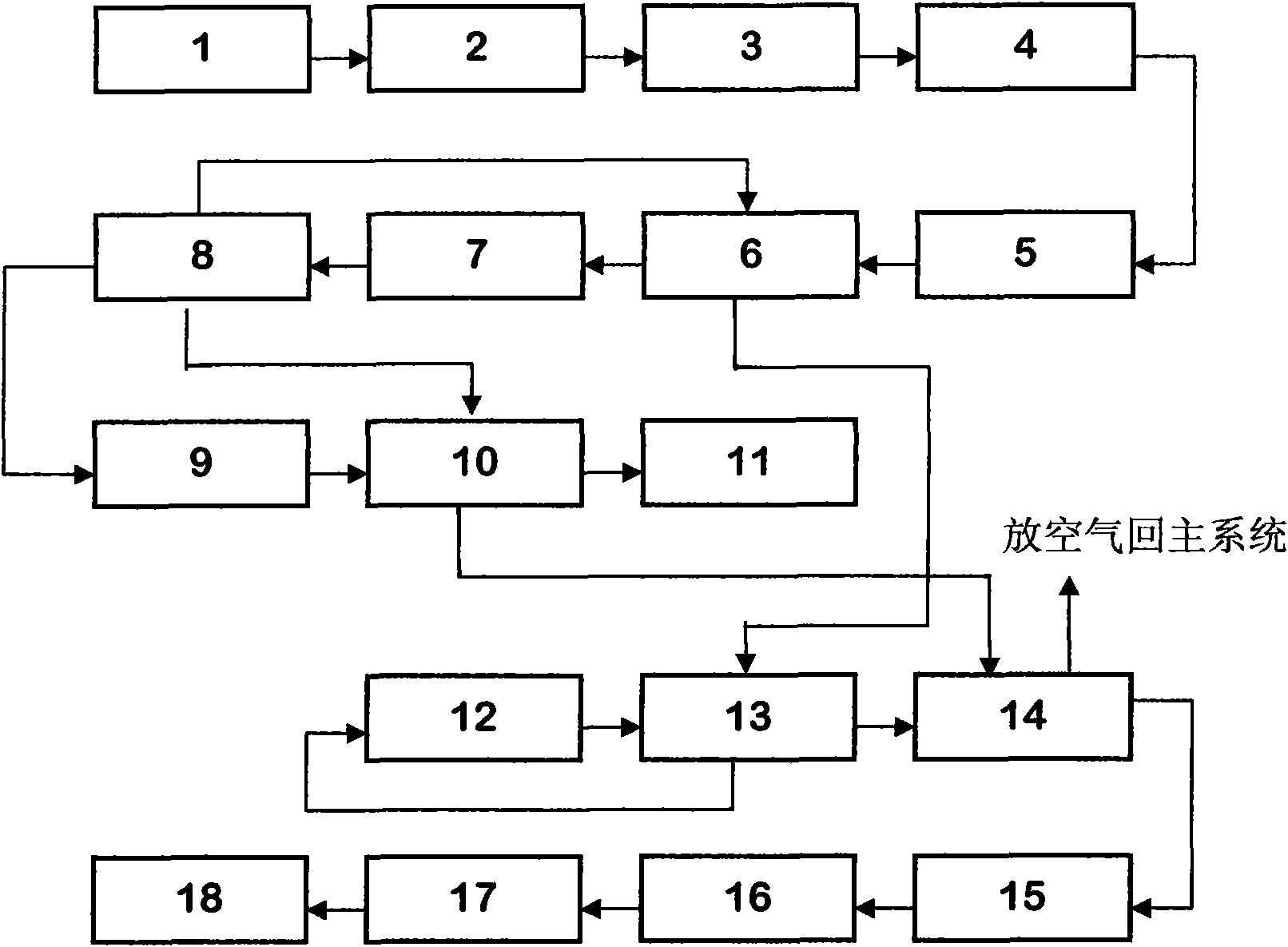

[0017] Taking coal as a raw material to produce synthetic ammonia, methanol or hydrogen, the carbon dioxide raw material gas produced by pressure swing adsorption decarbonization and venting is used as an example to prepare industrial-grade and food-grade liquid carbon dioxide, and the present invention will be further described in conjunction with the accompanying drawings:

[0018] The content of carbon dioxide in the carbon dioxide feed gas is generally 75% to 90%, which contains more hydrogen, carbon monoxide, nitrogen, sulfide, and hydrocarbon impurities such as methane, ethane, and benzene. The carbon dioxide raw material gas outside the boundary area is introduced into the buffer 2 through the nozzle 1 in sequence (the buffer can use an air bag or a gas cabinet) for buffering, and after buffering, it enters the carbon dioxide compressor 3 and pressurizes to 2.0MPa~4.0MPa, preferably It is 2.8MPa~3.5MPa; the pressurized carbon dioxide raw material gas enters the desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com