Method for recycling ammonia from raw morpholine

A recovery method, morpholine technology, which is applied in the field of ammonia recovery in the crude morpholine production process, can solve the problems of environmental pollution, high power consumption, and difficulty in realization, and achieve the effect of simple process and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

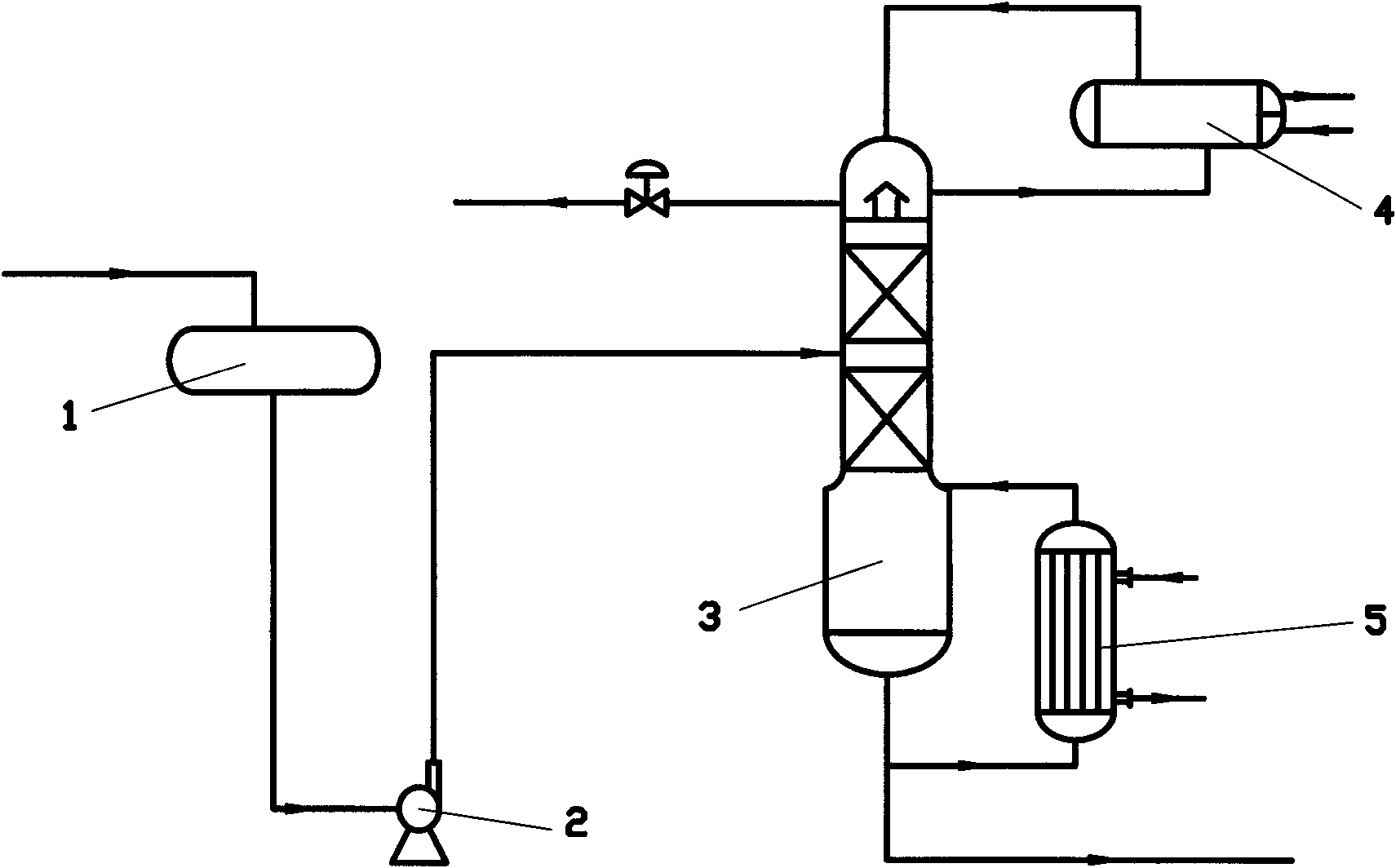

[0019] With the crude morpholine generated in the morpholine preparation process as raw material, the crude morpholine tank 1 is set and the crude morpholine is pumped into the deamination by the feed pump 2 (if the pressure of 1 is increased, the pump can be directly fed into 3 to save electricity). Tower, deamination tower 3 is heated by steam under pressurized state, its pressure is controlled at 1.3MPa, and the heating steam is 1.8MPa. Maintain the temperature at the top of the sulfur refining tower at 35°C, the top condensate from the condenser 4 flows back into the overflow weir of 3, part of it goes over the overflow weir and passes through the primary separator as the reflux in the tower, and part of it is taken out as the produced product , so that the recovery of ammonia is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com