Method for producing alumina by using sodium bicarbonate to decompose sodium aluminate solution

A technology of sodium bicarbonate and aluminum hydroxide, used in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve problems such as increased investment, atmospheric pollution, and violent reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 One-time sufficient addition of sodium bicarbonate to decompose bauxite eluate

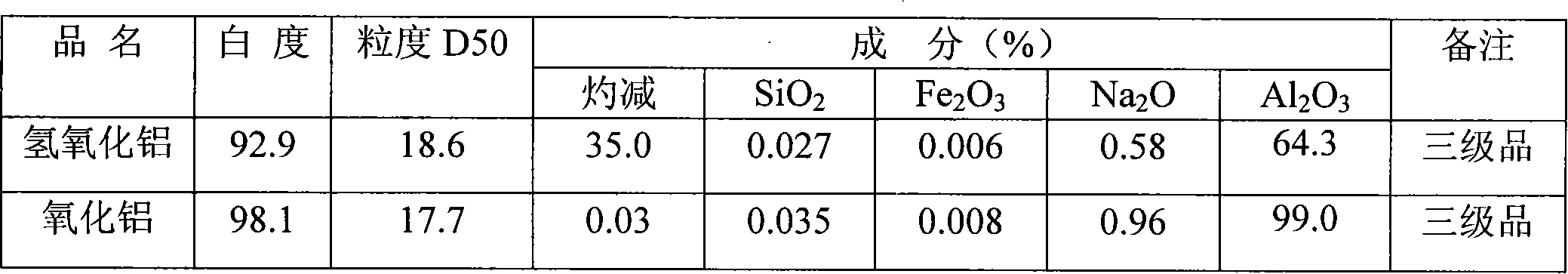

[0019] Under stirring conditions, the temperature is controlled at 80°C, the total alkalinity (as Na 2 O) is 172g / L, Al content (as A1 2 o 3 Calculated) is 185g / L, caustic alkali content (as Na 2 (O meter) add 100g / L sodium bicarbonate solution in the bauxite eluate of 156g / L, the addition of sodium bicarbonate is controlled at the ratio of the equivalent number of caustic alkali with eluate to be 1.05, decomposes 2 hours, decomposes The rate reached 99.65%. The obtained aluminum hydroxide product was roasted and kept at 1200° C. for 4 hours to obtain an alumina product. The analysis results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2

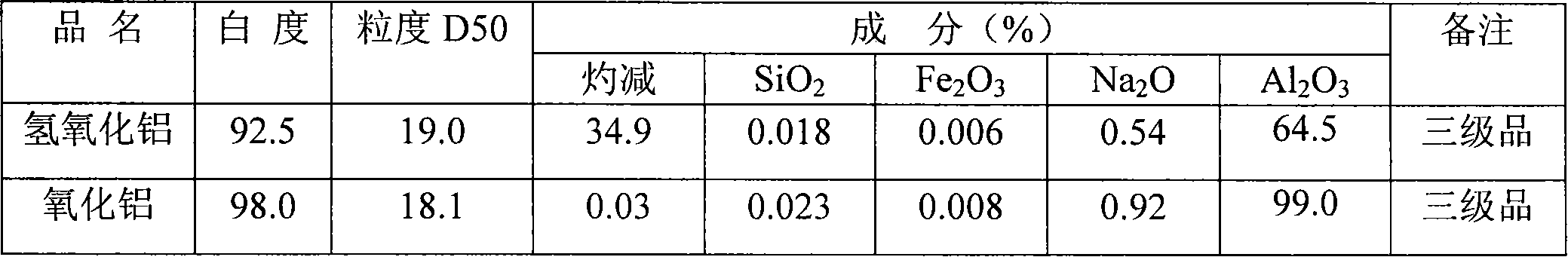

[0022] Example 2 Add a sufficient amount of sodium bicarbonate and sodium carbonate mixed solution to decompose the bauxite eluate

[0023] Under stirring conditions, the temperature is controlled at 60 ° C, the total alkalinity (as Na 2 O) is 173g / L, Al content (as A1 2 o 3 Calculated) is 186g / L, caustic alkali content (as Na 2 (O meter) is the mixed solution that sodium bicarbonate content is 80g / L, sodium carbonate content is 40g / L in the bauxite stripping solution that adds sodium bicarbonate content of 156g / L, and the addition of mixed solution is controlled at the total equivalent number of its sodium bicarbonate The ratio to the total equivalent number of caustic in the eluate is 0.95, and the decomposition rate reaches 99.7% after 5 hours of decomposition. The obtained aluminum hydroxide product was roasted and kept at 1200° C. for 4 hours to obtain an alumina product. The analysis results are shown in Table 2.

[0024] Table 2

[0025]

Embodiment 3

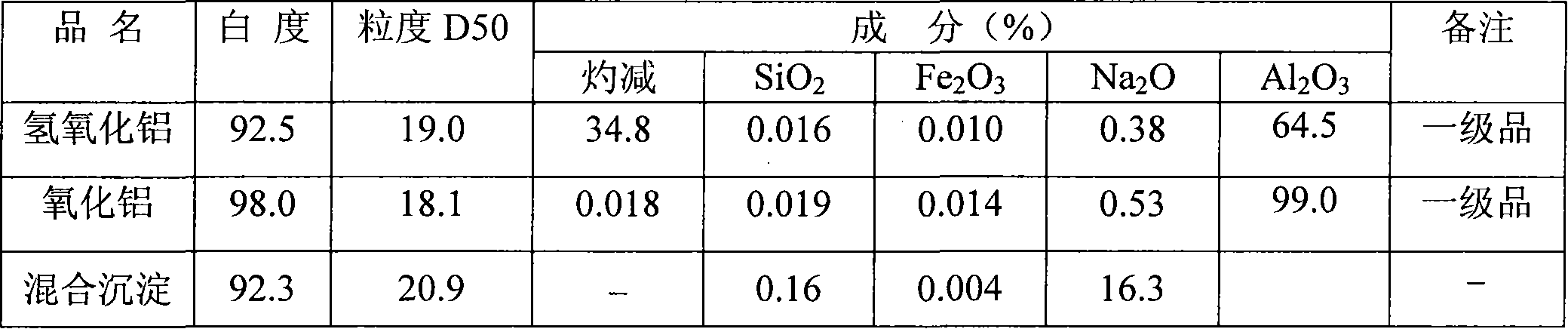

[0026] Example 3 The first step is to control the amount of sodium bicarbonate to decompose the bauxite eluate

[0027] Under stirring conditions, the temperature is controlled at 80°C, the total alkalinity (as Na 2 O) is 173g / l, Al content (as A1 2 o 3 Calculated) is 186g / L, caustic alkali content (as Na 2 (O meter) is the mixed solution that sodium bicarbonate content is 90g / L, sodium carbonate content is 30g / L in the bauxite stripping solution that adds sodium bicarbonate content of 156g / L, and the addition of mixed solution is controlled at the total equivalent number of its sodium bicarbonate The ratio to the total equivalent number of caustic in the eluate is 0.8, and the decomposition rate reaches 90.2% after 5 hours of decomposition. The obtained aluminum hydroxide product is roasted and kept at 1200°C for 4 hours to obtain an alumina product; a sufficient amount of sodium bicarbonate is added to the remaining mother liquor within 2 hours to obtain a mixture of alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com