Dam concrete and preparation method thereof

A concrete and concrete structure technology, applied in the field of building materials, can solve the problems of poor physical properties such as concrete durability and corrosion resistance, and achieve the effect of strong durability and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

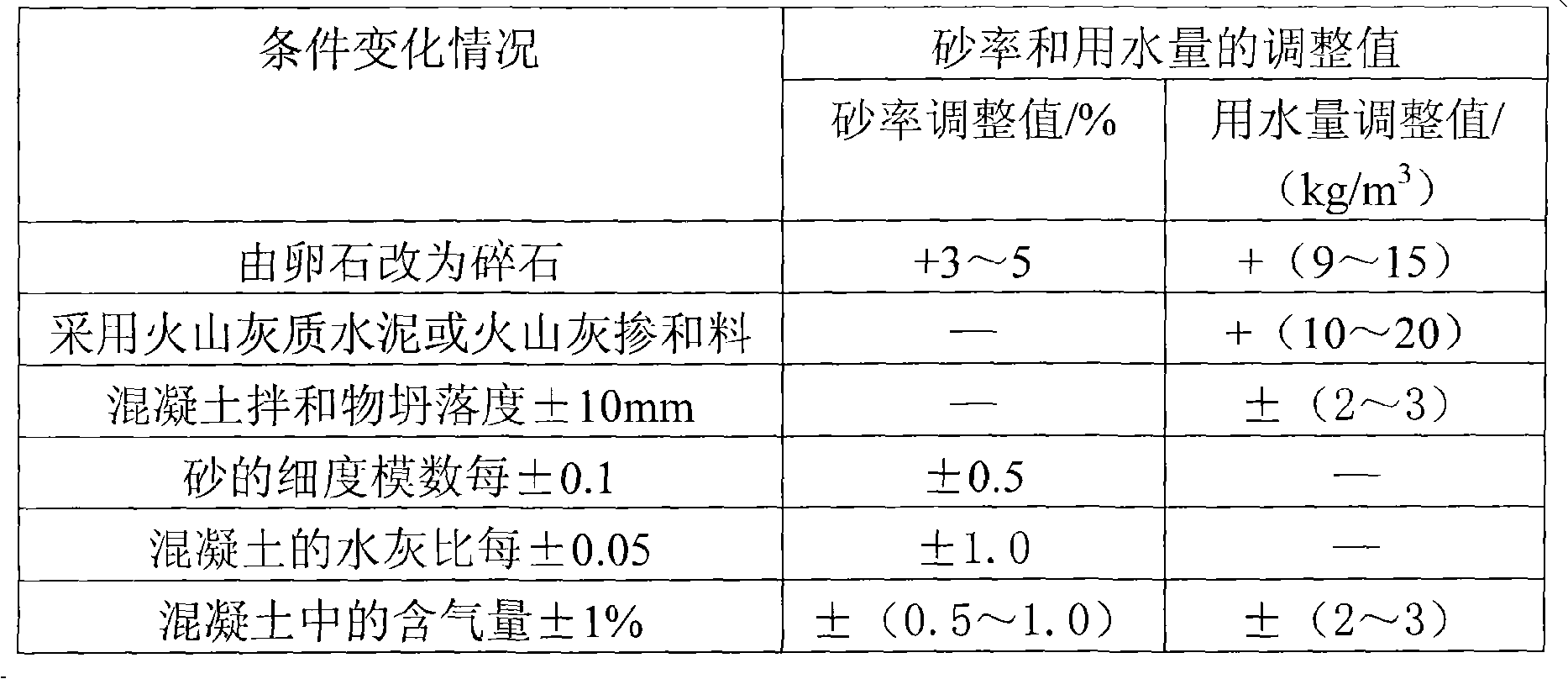

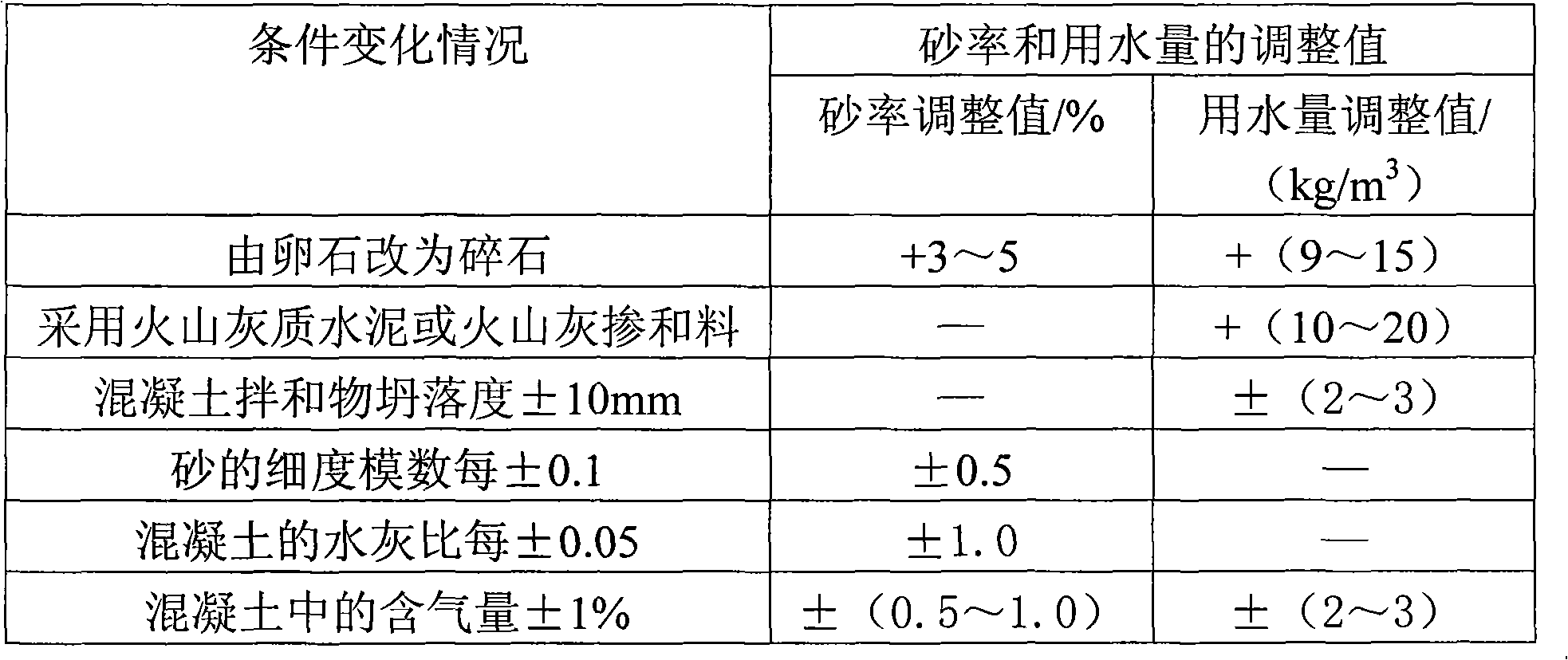

Method used

Image

Examples

Embodiment Construction

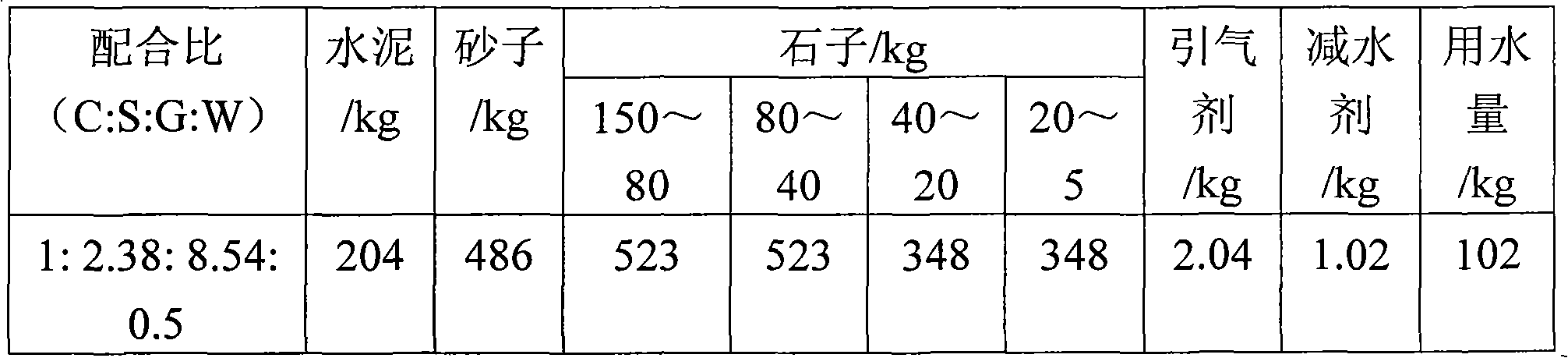

[0015] The strength grade of concrete for a dam is C25, the strength guarantee rate is 95%, and the impermeability grade of concrete is P 8 . The slump of the concrete mixture is 80mm. The concrete ingredients of dams include cement, water, sand, gravel, silica fume powder, air-entraining agent rosin soap, and water-reducing agent wood calcium.

[0016] Coarse aggregate in concrete is pebbles, the maximum particle size is 150mm, and the gradation is: extra large stones (150-80mm), large stones (80-40mm), medium stones (40-20mm) and small stones (20-5mm ) each occupy a certain proportion, the ratio is 30:30:20:20, and the density is 2.70g / cm 3 , the surface water content of medium stones and small stones is 0.3% and 0.8%, and the large stones and extra large stones are in a saturated surface dry state. The fine aggregate in the concrete is river sand with a fineness modulus of 2.60 and a density of 2.65g / cm 3 , the surface moisture content is 4.5%.

[0017] Slag cement wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com