Resonant intake tube of natural gas engine

A technology of engine and natural gas, applied in the field of resonant intake pipe structure of natural gas engine, can solve the problems affecting the working stability, economy and emission performance of the engine, gas pressure fluctuation phenomenon, combustion process difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

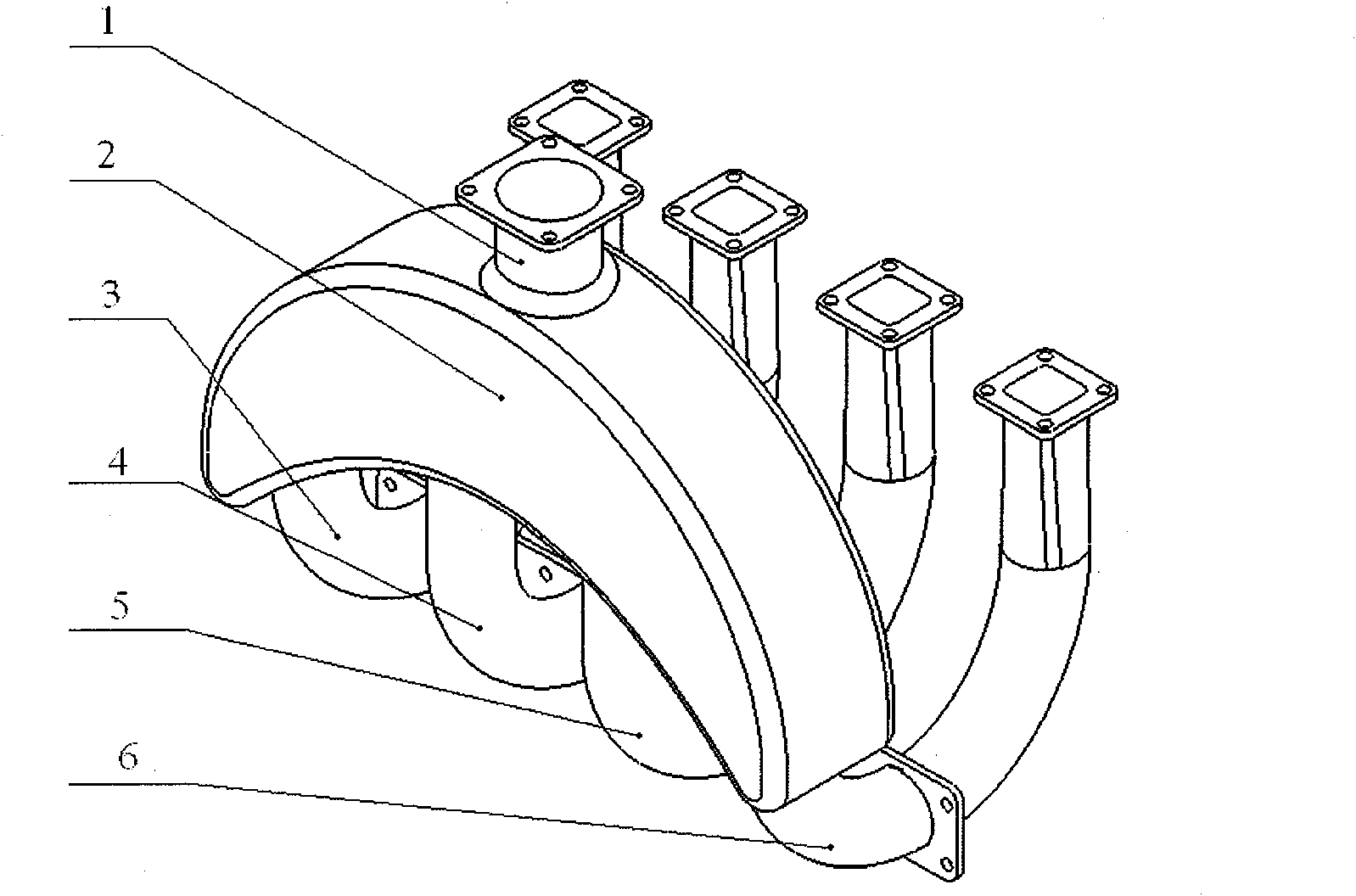

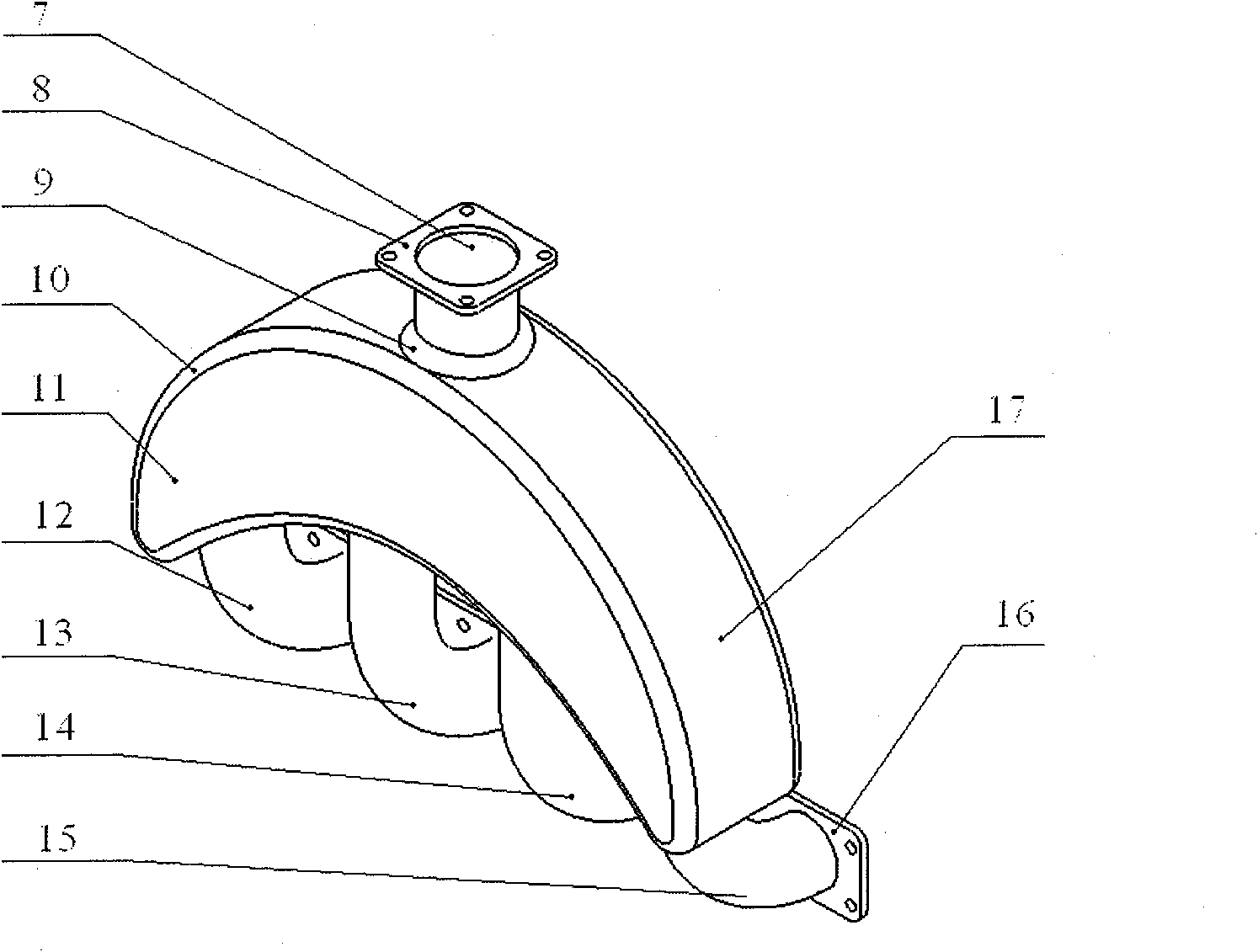

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

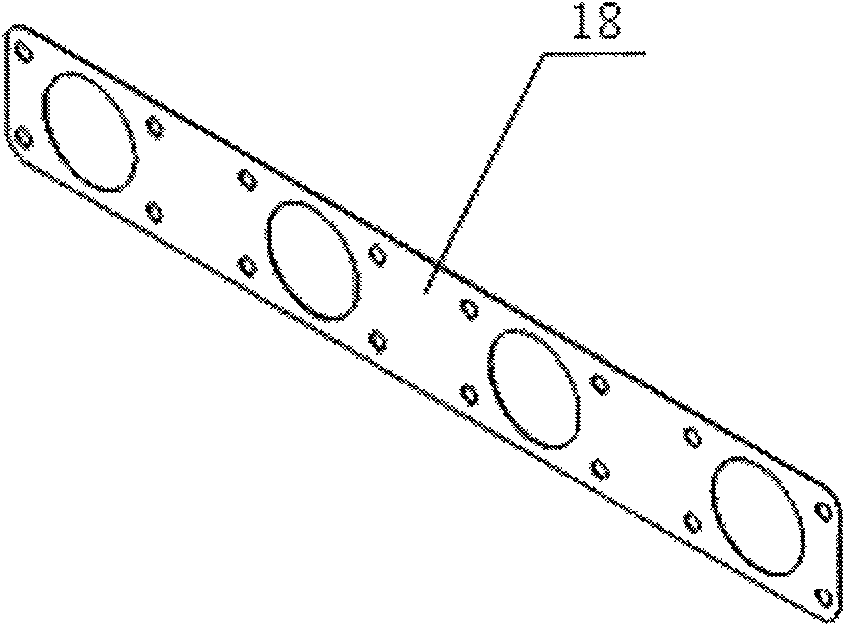

[0018] A resonant intake pipe for a natural gas engine is composed of an intake manifold, a resonant cavity and an intake manifold. The length of the intake manifold is 50mm, and the inner diameter is 60mm. The gas main pipe and the resonant cavity are connected by a rounded corner with a radius of 10mm to reduce the energy loss when the air intake main pipe flows to each manifold. The volume of the resonant cavity is 2.5L. A section of arc surface, the entire resonant cavity presents a crescent shape, and the four intake manifolds are symmetrical in pairs along the plane passing through the center line of the intake manifold and perpendicular to the two crescent-shaped sides of the resonant cavity, with short manifold lengths on both sides is 500mm, but the length of the path that the air flows from the inlet of the intake manifold to the outlet of each manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com