Anticorrosive device of oil storage tank during testing seawater pressure

An oil storage tank and anti-corrosion technology, applied in the direction of applying stable tension/pressure to test material strength, material electrochemical variables, liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of large consumption and oil storage The tank anti-corrosion device has high cost and is completely consumed, so as to achieve the effect of corrosion inhibition, avoiding corrosion and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

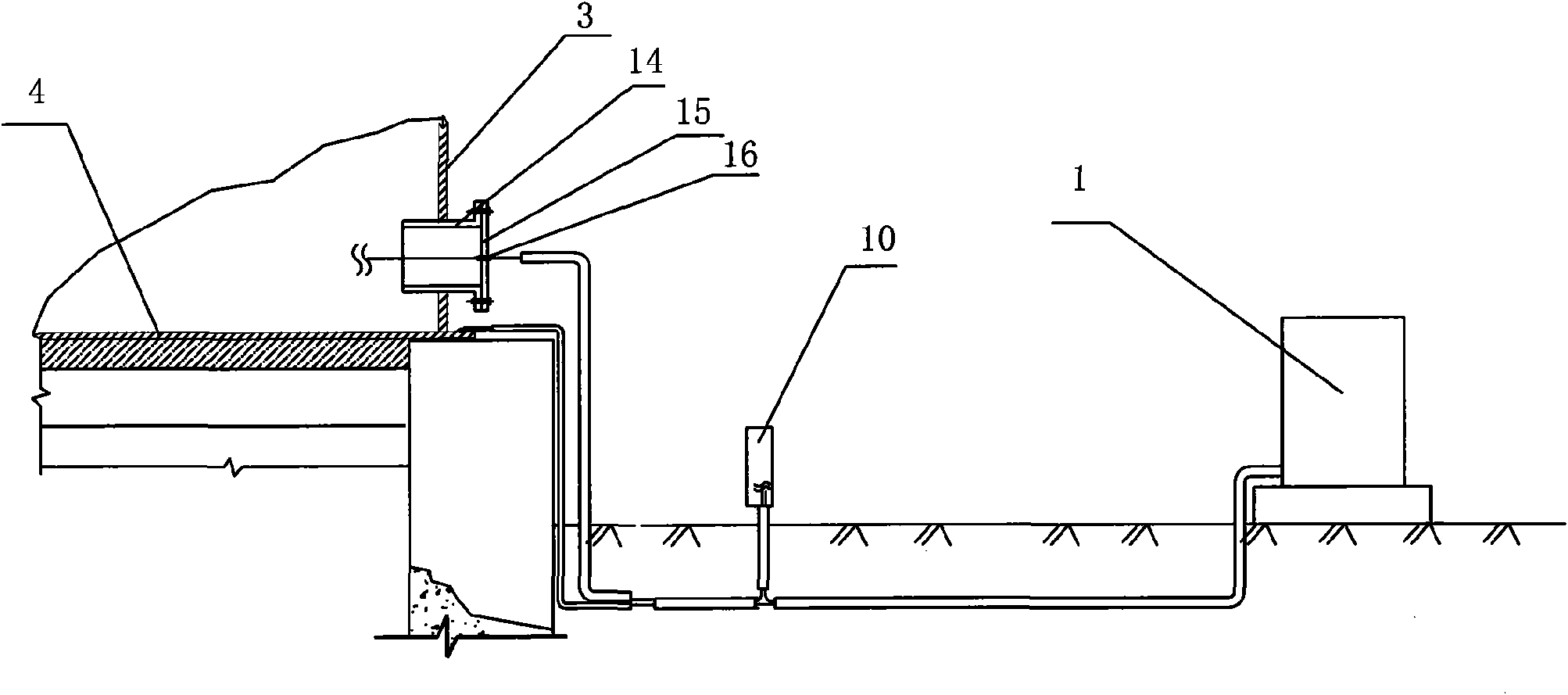

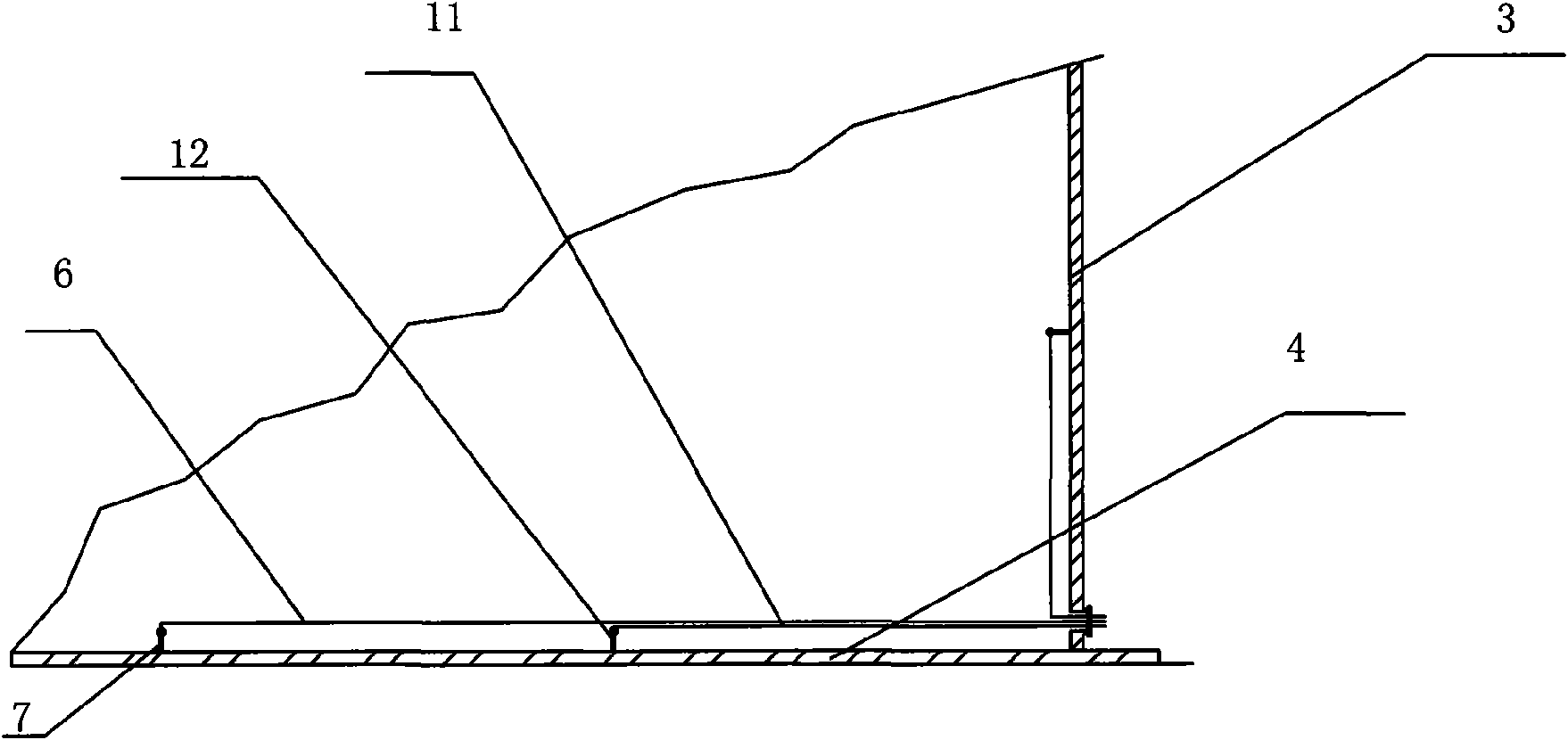

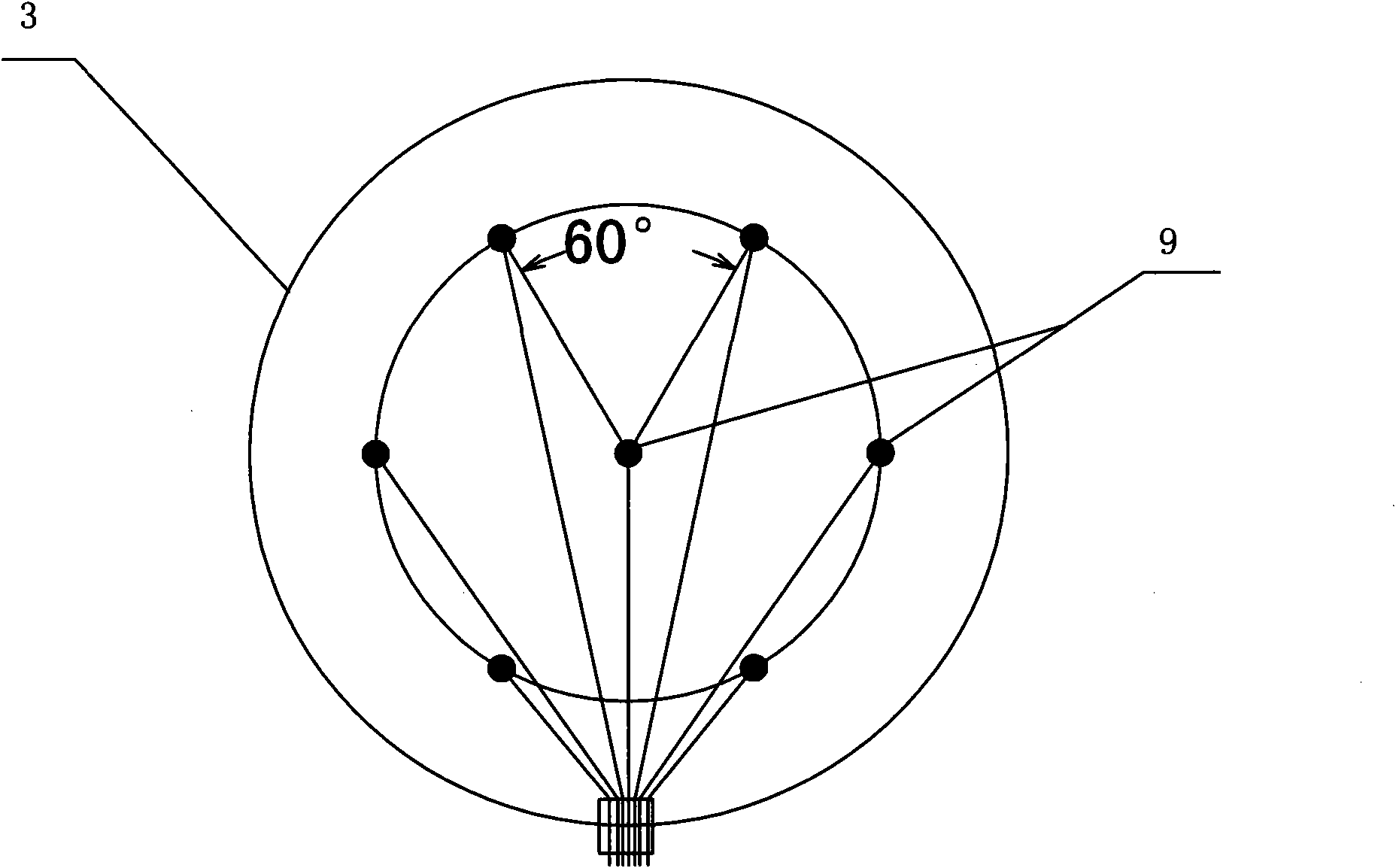

[0021] An anti-corrosion device for an oil storage tank during a seawater pressure test, which includes a potentiostat 1, a cathode cable 2 drawn out from the potentiostat 1 is connected to the bottom plate 4 of an oil storage tank 3, and a reference cable drawn out from the potentiostat 1 The zero position connection negative line 5 in the signal line is connected to the bottom plate 4 of the oil storage tank 3, and the signal reference electrode line 6 in the reference signal line drawn by the potentiostat 1 is connected to the signal on the tank body of the oil storage tank 3. The reference electrode 7 is connected, and the anode cable 8 drawn from the potentiostat 1 is connected to the mixed metal oxide auxiliary anode 9 installed in the oil storage tank 3 .

[0022] It also includes a junction box 10, a plurality of test reference electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com