Method and device for detarring small-sized biomass gasifier

A gasification furnace and biomass technology, applied in the field of gasification furnaces, can solve the problems of high tar content, low gas calorific value, unstable operation, etc., and achieve the effects of simple device structure, improved operation stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

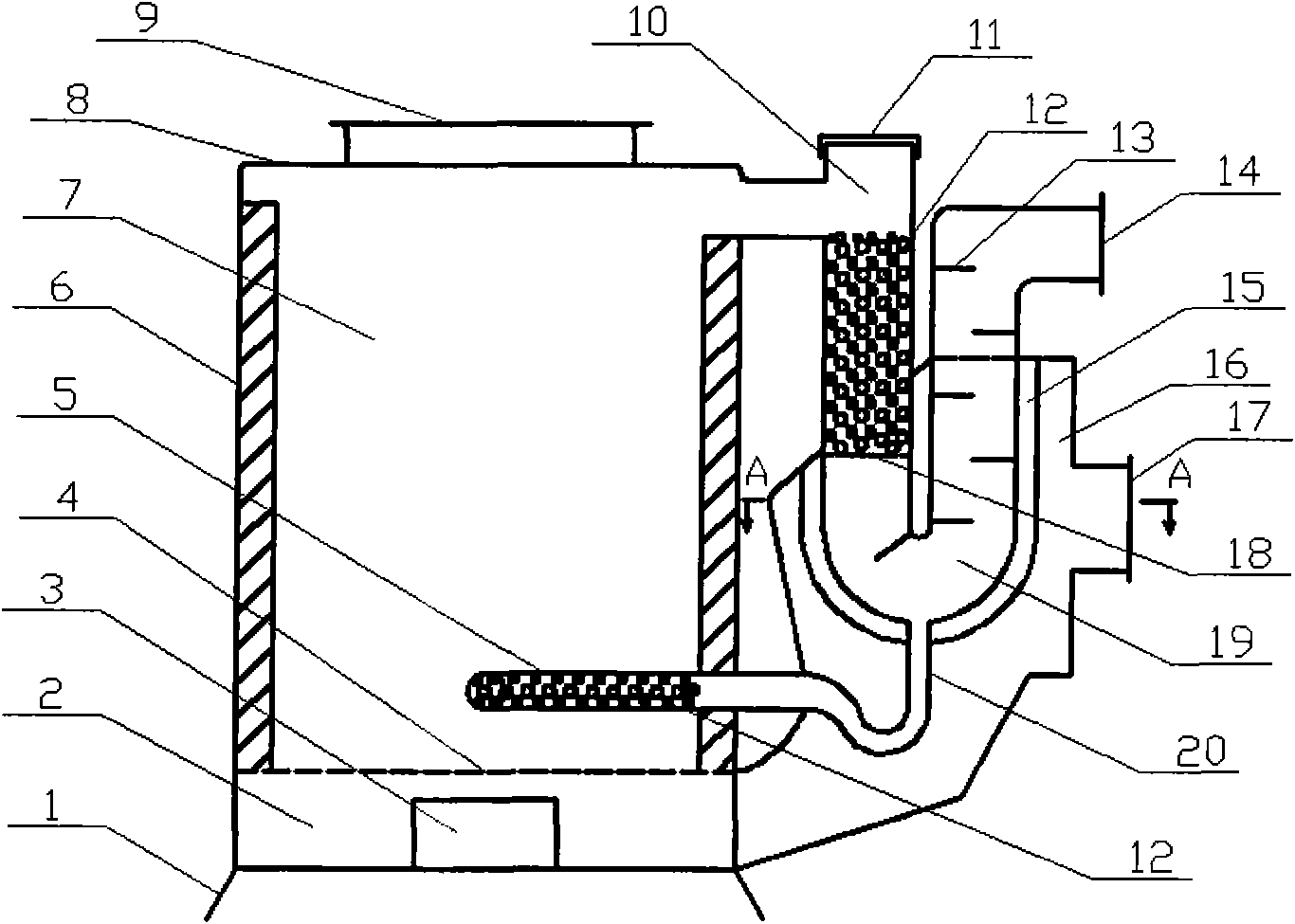

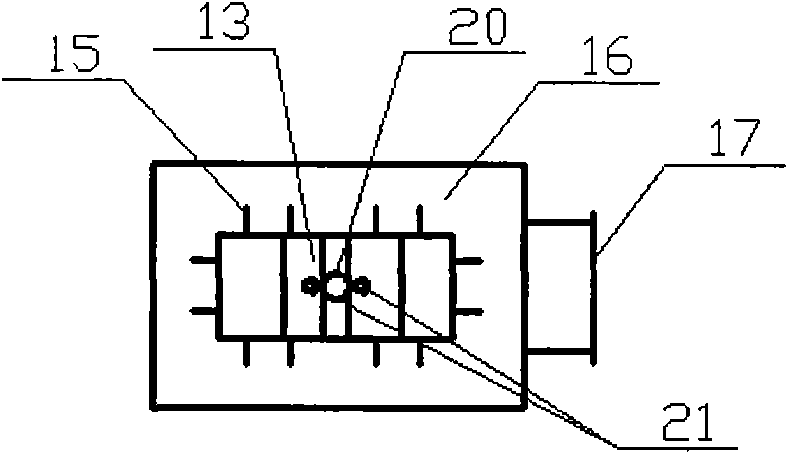

[0016] exist figure 1 Among them, the gasifier furnace body 6 is a cylindrical shape made of steel plate, supported by a foot 1, the ash chamber 2 is located below the grate 4, the ash chamber is provided with an ash discharge port 3, and a furnace cover for sealing is provided on the top 8. Biomass raw materials are added from the raw material inlet 9 on the top of the furnace, and the gasification agent (air) is blown in from the air inlet pipe 17 on the right side of the furnace body, and first flows through the air preheating chamber 16 to replace the gas in the purification and separation chamber 19. After heating up, it flows through the grate 4 and enters the furnace 7, and the gas produced is discharged from the top of the gasifier.

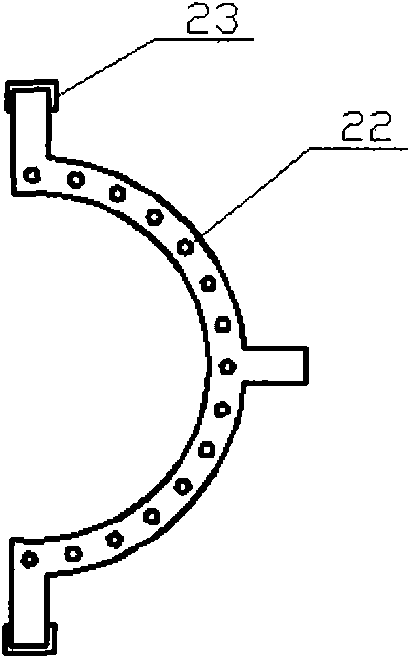

[0017] The gas produced by the gasification furnace is collected from the top of the furnace and then flows into the catalytic chamber 10 set outside the furnace. There is a movable cover 11 on the top of the catalytic chamber for the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com