Ceramic plate stamping technology and ceramic plate stamping device

A technology of ceramic plate and process, applied in the field of ceramic plate embossing process and its device, to achieve good economic benefits, simple structure, and rich effect on the surface of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

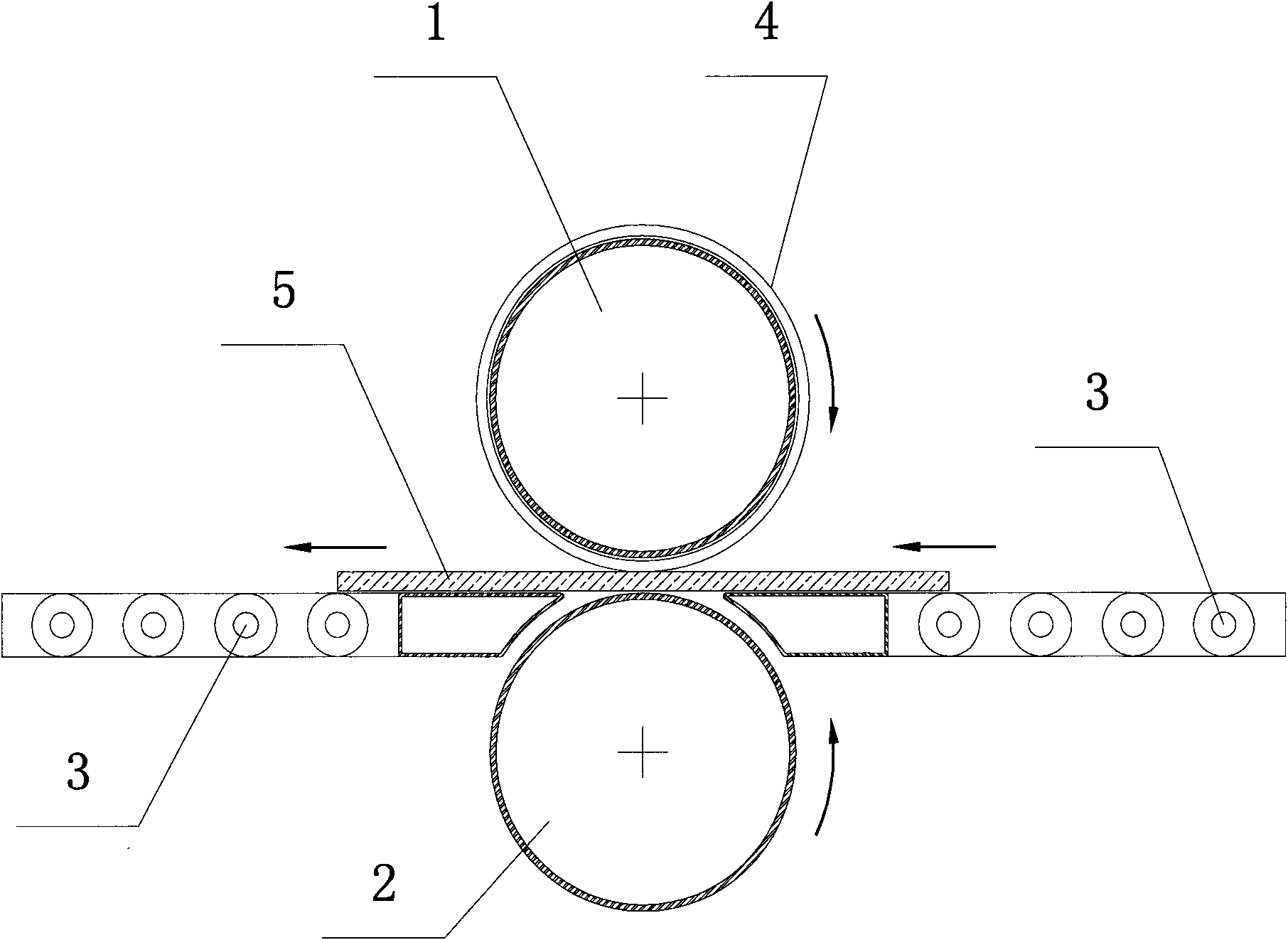

[0024] refer to figure 1 An embodiment of the ceramic plate imprinting device of the present invention, the ceramic plate imprinting device includes a main roller 1, an auxiliary roller 2, a transmission device and a mold 4, the transmission device is arranged horizontally, and the main roller 1 and the auxiliary roller 2 The central connection line is perpendicular to the transmission device, the mold 4 is set on the main roller 1, the transmission device is a roller table 3, and the roller table 3 is composed of several cylindrical rollers arranged horizontally. The transmission device It can also be a conveyor belt, the main roller 1 is a solid or hollow cylindrical metal roller, and the auxiliary roller 2 is a solid or hollow cylindrical metal roller or a circular roller. The distance between the main roller 1 and the auxiliary roller 2 can be adjusted to adapt to ceramic plates of different thicknesses.

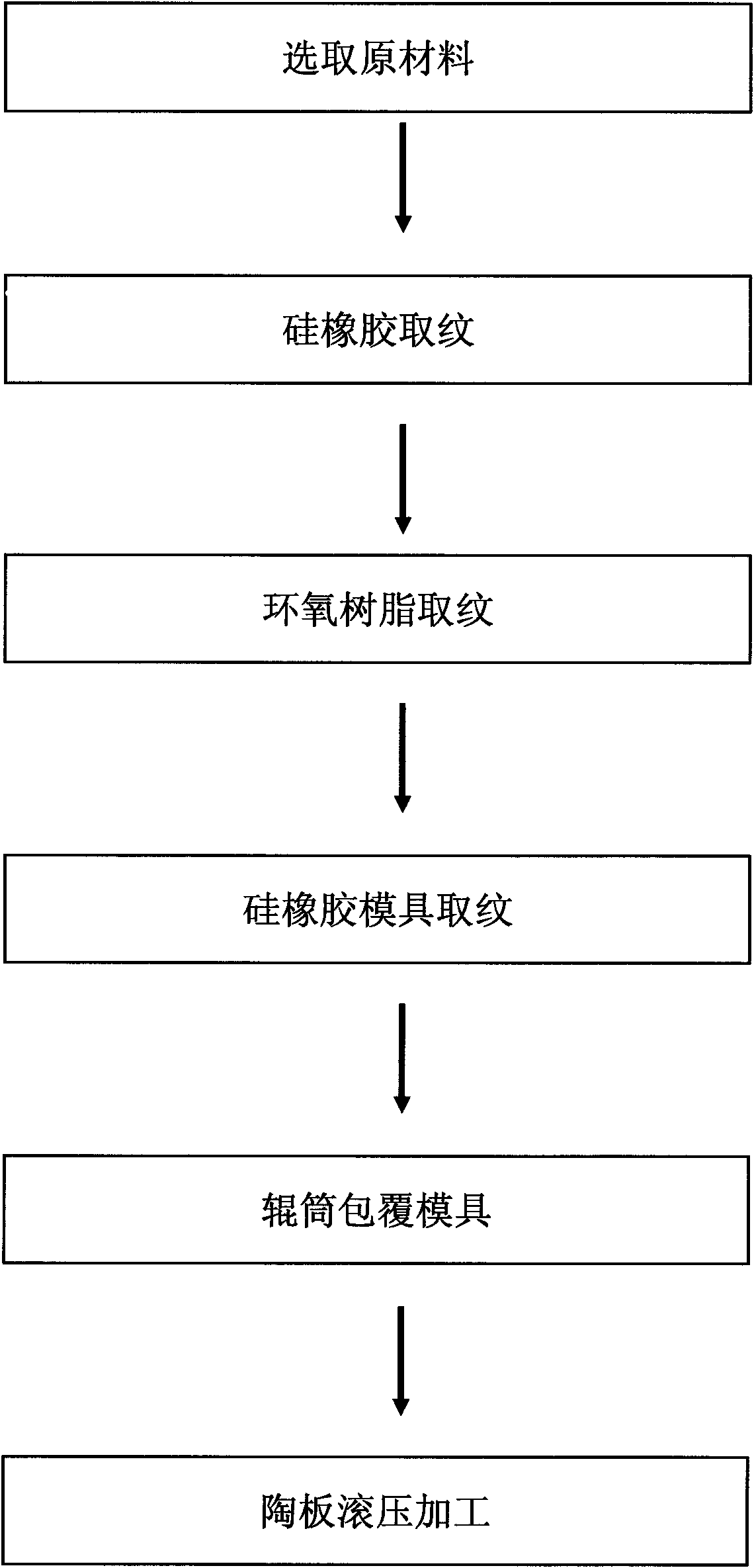

[0025] refer to figure 2 It is an embodiment of the ceramic plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com